How Do They Differ from Standard Tact Switches

Low-profile tact switches differ from standard switches mainly in height, travel distance, and actuation feel. Standard switches offer longer travel (0.25mm+) and a softer, deeper click, while low-profile versions provide a shorter, sharper "snap" (0.1mm - 0.2mm travel) and are designed for high-density mounting where vertical clearance is critical.

Comparison: Standard vs. Low-Profile

When selecting components, you are always trading physical feel for space. Here is the breakdown:

| Feature | Standard Tact Switch | Low-Profile Tact Switch |

| Height | 3.5mm - 12mm+ | 0.35mm - 2.0mm |

| Mounting | DIP (Through-Hole) or SMD | Almost exclusively SMD |

| Actuation Travel | Long (0.25mm - 0.5mm) | Short (0.10mm - 0.20mm) |

| Tactile Feel | Deep, distinct click | Sharp, crisp "snap" |

| Life Cycle | 100k - 1M cycles | 50k - 500k cycles (typically) |

| Actuation Force | Wide Range (100gf - 500gf) | Limited Range (160gf - 300gf) |

If you are working with larger industrial boards where space isn't an issue, you might prefer the robustness discussed in tact dip switch fundamentals. However, for a smartwatch, the low-profile option is the only viable choice.

What Are the Key Design Challenges? (The Engineering Reality)

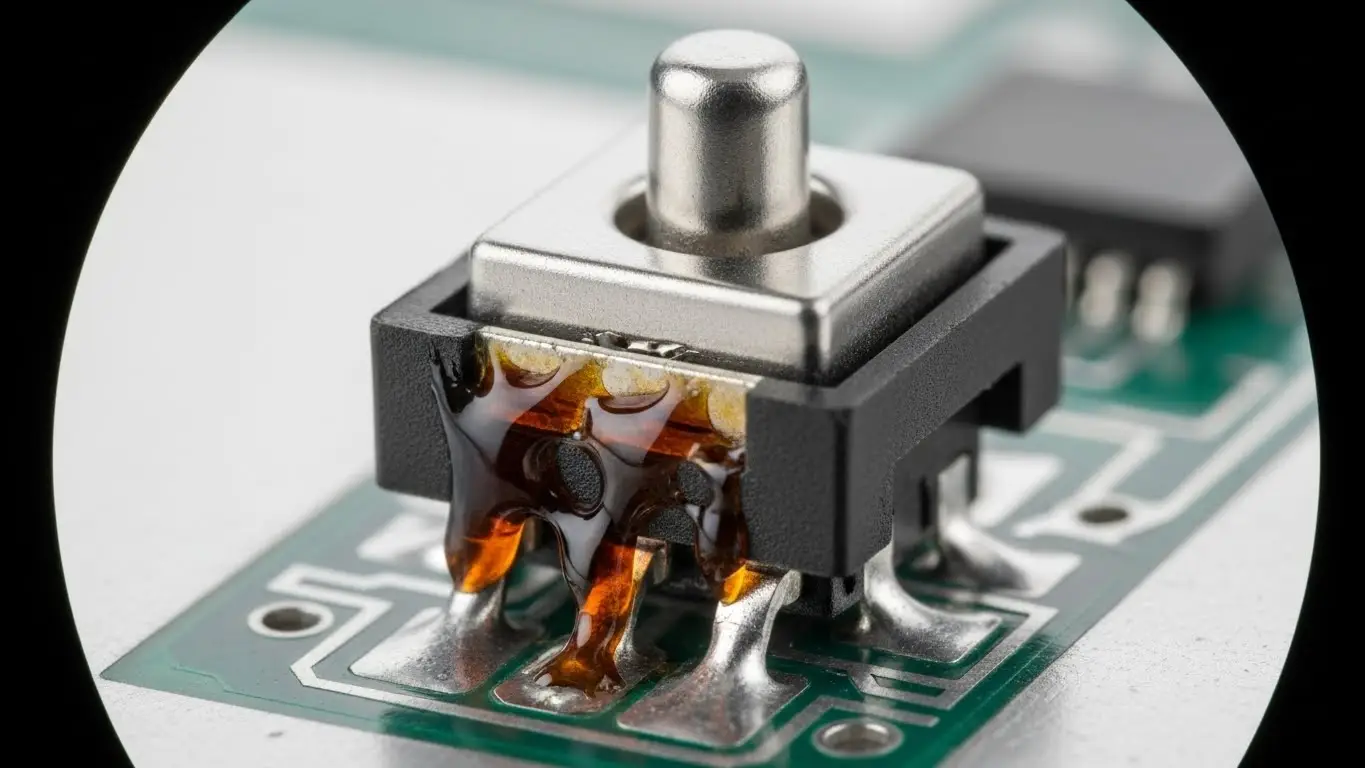

Designing with low-profile tact switches introduces unique challenges, specifically flux contamination during soldering and pick-and-place accuracy. Because the switch body is so close to the PCB, wicking actions can draw molten flux inside the contact area, insulating the dome and causing switch failure before the device even leaves the factory.

The "Silent Killer": Flux Wicking

I have spoken with production engineers who have lost entire batches of boards to this. When you wave solder or reflow a switch that sits only 0.5mm off the board, the capillary action is strong.

- The Symptom: The switch clicks perfectly but sends no signal. The flux has coated the internal contact.

- The Fix: You must use a strictly controlled reflow profile. Avoid aggressive washing of non-sealed switches. If your environment is harsh, you must upgrade to a sealed version. Consult a sealed tact switches guide to understand the protective barriers available.

Pick-and-Place Nightmares

Another specific anecdote from the assembly line involves the nozzle height.

- Too Low: You crush the delicate actuator, permanently deforming the metal dome.

- Too High: The vacuum fails, and the part is dropped.With ultra-miniature switches (like 2mm x 3mm footprints), the "keep-out" zone for the nozzle is tiny. Programming the Z-axis height on the mounting machine requires extreme precision.

Where Are Low-Profile Tact Switches Used?

Low-profile tact switches are ubiquitous in space-critical applications, including smartphones (volume/power buttons), wearable health trackers, Bluetooth headsets, hearing aids, and slim membrane keyboards. They are also increasingly found in automotive interiors for steering wheel controls and key fobs where sleek, flush surfaces are desired.

Industry-Specific Use Cases

- Wearables: In a fitness tracker, the battery takes up 80% of the space. The switch must sit flush against the casing to prevent a "bump" on the user's wrist.

- Medical Devices: For handheld glucose monitors or hearing aids, the switch must be reliable but microscopic.

- Consumer Audio: High-end noise-canceling headphones use these for the hidden control buttons on the ear cups.

If these devices are expected to be used outdoors or in sweaty environments (like gym wearables), understanding the difference between simple sealing and true waterproofing is vital. Review waterproof tactile switches explained for IP67/IP68 distinctions.

Can Low-Profile Switches Be Illuminated?

Yes, low-profile tact switches can be illuminated, but the design is complex. Manufacturers typically use side-firing LEDs mounted next to the switch or integrate a tiny LED die directly into the switch housing. However, due to the limited vertical space, the "light pipe" effect is harder to achieve uniformly compared to taller switches.

The Space vs. Light Trade-off

Adding light requires height. A standard illuminated switch might be 4mm tall to allow room for the LED. Creating a 1mm tall illuminated switch is a marvel of optical packaging.

For a broader look at how light and haptics interact, check out how illuminated tact switch works. In low-profile designs, you will often see "halo" illumination (light around the button) rather than the button cap itself glowing, simply because there isn't enough thickness in the cap to diffuse the light.

Summary and Next Steps

Understanding what is a low-profile tact switch reveals a component that punches well above its weight. It allows for the sleek, modern aesthetic of today's electronics while providing the critical human-machine interface we rely on.

However, they are not "drop-in" replacements for standard switches. They require:

- Precise Soldering: To avoid flux contamination.

- Careful Mounting: To prevent dome crushing.

- Correct Specification: Balancing life cycle with actuation force.

Frequently Asked Questions

There is no single standard, but "low-profile" generally refers to switches under 2.0mm in height. Ultra-low-profile models can be as thin as 0.35mm to 0.6mm, often used in smartphones and smartwatches.

Not by default. Standard low-profile switches are IP40 rated (dust resistant but not waterproof). You must specifically select IP67 or IP68 rated models if your device needs protection against sweat, rain, or immersion.

Yes. Because the internal travel distance is shorter (often 0.15mm vs 0.30mm), the click feels sharper and "faster" (crisp), whereas taller switches often have a deeper, softer actuation feel.

It is difficult and risky. Due to the small size and plastic housing being close to the pins, hand soldering often melts the casing or allows flux to wick into the switch mechanism. Reflow soldering with a controlled profile is highly recommended.

The most common cause is flux contamination. During soldering, liquid flux can be drawn inside the switch via capillary action, coating the contacts and insulating them. This results in a switch that clicks but sends no electrical signal

They generally range from 50,000 to 500,000 cycles. While some high-end metal dome variants can reach 1 million cycles, the compact nature often means a slightly lower durability rating compared to larger, ruggedized industrial switches.