Waterproof Tactile Switches Explained

A waterproof tactile switch is a momentary push-button designed to interact with a circuit while preventing the ingress of contaminants like dust, moisture, and water. These switches rely on a specific Ingress Protection (IP) rating—most commonly IP67—to define their durability. Unlike standard switches, waterproof variants utilize internal seals, such as silicone rubber membranes or O-rings, to protect the metal dome contact mechanism. They are essential components in environments where electronics are exposed to rain, wash-down processes, or high humidity, ensuring reliable electrical connectivity and distinct tactile feedback even in harsh conditions.

What Defines a Waterproof Tactile Switch?

To understand the waterproof variant, you first need to understand what a standard tact switch is. A standard tactile switch is an electromechanical device that provides a perceptible "click" or tactile bump when pressed, completing an electrical circuit.

However, standard switches are vulnerable to oxidation and failure when exposed to moisture. A waterproof tactile switch (often called a sealed switch) integrates a protective barrier. This barrier does not alter the fundamental function of the switch but significantly extends its lifespan in outdoor or industrial applications.

Key Components of Protection:

- Sealing Member: Usually a silicone rubber stem or membrane.

- Housing: Often made from high-temperature thermoplastics (like Nylon 6/6) to withstand soldering heat and environmental stress.

- Contacts: Silver or gold-plated contacts to resist corrosion inside the sealed chamber.

How Does the Sealing Mechanism Work?

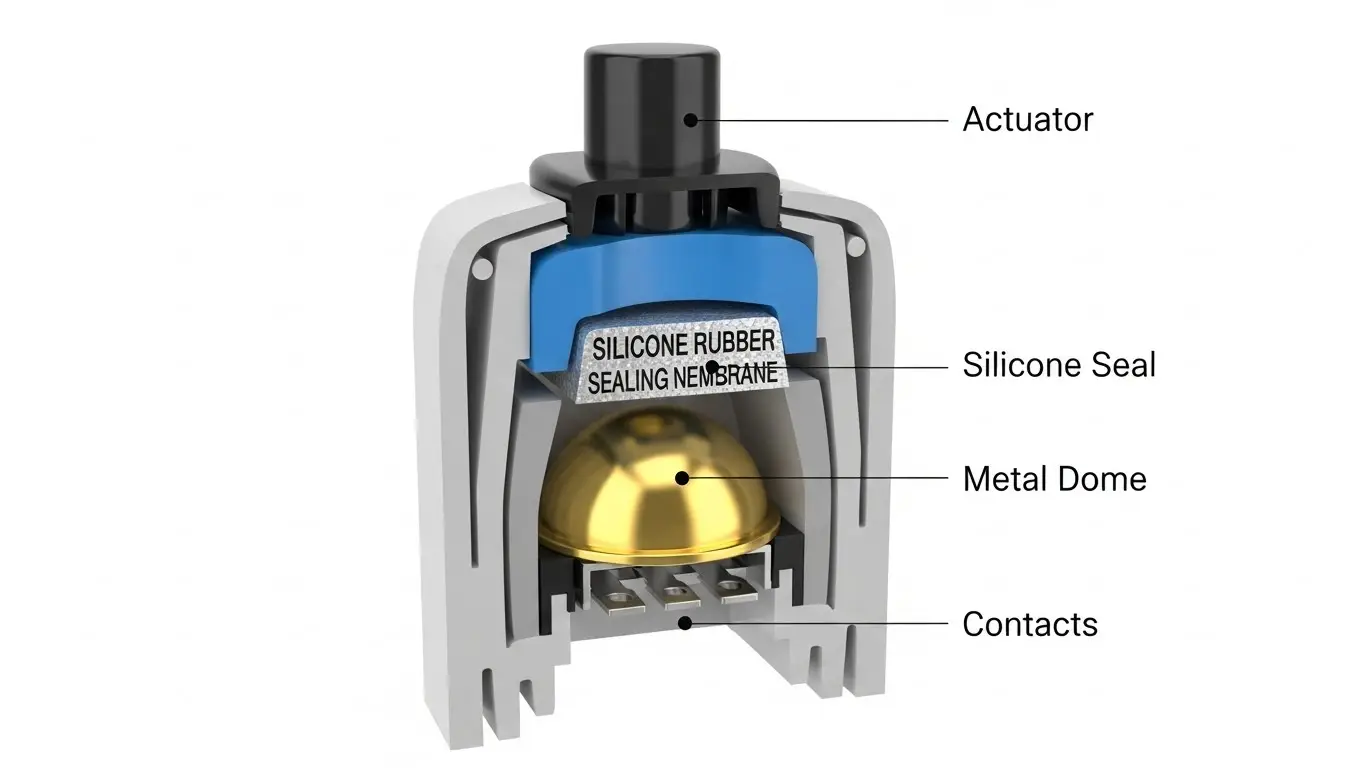

The functionality mirrors a standard switch, but the internal architecture is distinct. If you are familiar with how the internal mechanism works, you know that a metal dome collapses to create a connection.

In a waterproof version, the actuator (the part you press) pushes down on a flexible sealing membrane. This membrane transfers the force to the metal dome without creating an opening for water to enter. This allows the switch to be "washable" during PCB assembly and resistant to environmental elements during end-use.

What Do IP Ratings Mean for Switches?

People Also Ask: What is the difference between IP65 and IP67 switches?

The difference lies in the intensity of water exposure the switch can handle. An IP rating (Ingress Protection) consists of two digits: the first represents dust protection, and the second represents liquid protection.

- IP65: Dust-tight and protected against low-pressure water jets (like a splash).

- IP67: Dust-tight and protected against the effects of temporary immersion in water (usually up to 1 meter for 30 minutes).

Most high-quality waterproof tactile switches are rated IP67, making them suitable for the majority of consumer and industrial electronics.

IP Rating Comparison Table

| IP Rating | Dust Protection | Water Protection | Typical Use Case |

| IP65 | Dust Tight | Water Jets (Splash) | Indoor control panels, Kitchen appliances |

| IP67 | Dust Tight | Immersion (1m depth) | Outdoor tech, Wearables, Automotive |

| IP68 | Dust Tight | Continuous Immersion | Underwater equipment, Marine gear |

Why Use Sealed Switches in PCB Design?

People Also Ask: Do I need a sealed switch for my circuit board?

You need a sealed switch if your device will be used outdoors or if your manufacturing process involves washing. Even if the end product isn't for outdoor use, the sealed tact switches guide suggests using them to survive the automated soldering and washing process.

Benefits of Sealed Switches:

- Process Compatibility: They withstand the harsh chemicals and water wash-down stages of PCB assembly.

- Oxidation Prevention: The seal keeps sulfur and oxygen away from the silver contacts, preventing contact failure over time.

- Dust Resilience: In industrial environments, dust is as dangerous as water. These switches prevent particulate buildup that causes "double-clicking" or non-actuation errors.

Can Waterproof Switches Be Submerged?

People Also Ask: Are waterproof tactile switches submersible?

Yes, but only within specific limits defined by their rating. An IP67 switch can be submerged up to 1 meter for approximately 30 minutes. However, they are generally not designed for operation while submerged (actuating the switch underwater), but rather to survive the submersion without leaking.

For applications requiring deep-sea diving or continuous underwater usage, you would require an IP68 rating or a specialized magnetic reed switch setup rather than a standard mechanical tactile switch.

Frequently Asked Questions

Water-resistant implies the switch can handle humidity or light splashes (IP64/IP65), while waterproof (IP67+) indicates the switch can be submerged in water for a specific period without failure.

Sometimes. Because of the rubber sealing membrane, waterproof switches may feel slightly "softer" or have a more muted sound compared to the sharp "snap" of a non-sealed metal dome switch, though high-end models minimize this difference.

Generally, no. Tactile switches are low-power devices (logic level) intended for signaling (e.g., 12V DC, 50mA). For high currents, you need a power switch.

Manufacturers perform a "bubble test" or vacuum leak test. In a DIY setting, checking for continuity after submerging the switch (while not powered) and drying it off is a common verification method.

Key Takeaways

- Check the Rating: Look for IP67 for reliable protection against immersion and board washing processes.

- Internal Structure: Sealed switches use a membrane to separate the actuator from the electrical contacts.

- Manufacturing Safe: Waterproof switches are essential if your PCB assembly involves a washing phase.

- Application: Ideal for automotive, medical devices, and outdoor consumer electronics.

Conclusion

Waterproof tactile switches are critical components for modern electronics, offering the durability needed for portable and outdoor devices. By understanding the distinction between standard and sealed mechanisms, and choosing the correct IP rating, engineers can ensure their products withstand the elements.

If you are designing a product that requires robust interface components, ensure you review the specific datasheets to match the actuation force and life cycle to your needs.