What Is a Tact Switch and How Does It Function?

Tactile switches, commonly called tact switches, are compact, momentary push‑button switches widely used in modern electronics. They deliver a noticeable tactile “click” when pressed, providing physical feedback that confirms actuation. They’re essential components in devices ranging from computers and remotes to industrial controls and medical instruments

⚡ What Is a Tact Switch?

A tactile switch is a type of momentary switch, meaning it only closes the circuit while being pressed. When released, the circuit opens again. These switches are designed to be felt and sometimes heard, satisfying users that their input was registered correctly

They commonly come in surface-mount (SMT) or through-hole packages, with some variants offering right-angle mounting for design flexibility

🧩 Internal Structure & How They Operate

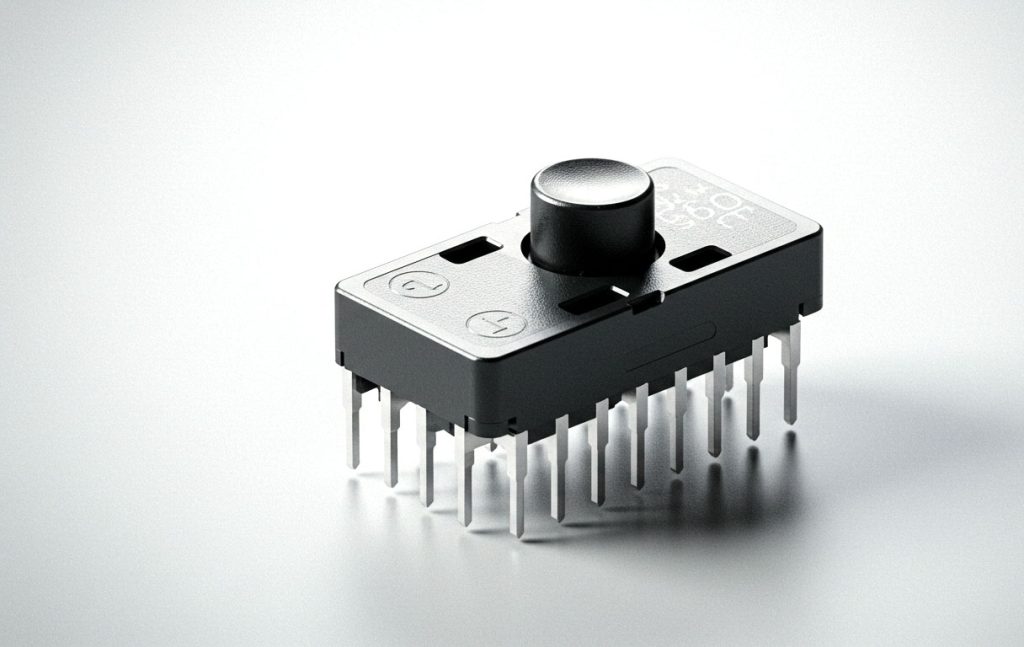

Though compact, tact switches consist of around five primary components:

- Cover – the outer protective shell, sometimes doubling as ground shielding

- Plunger/Stem – transfers the user’s push force

- Contact Dome – a metal or polymer dome that deforms to close the circuit

- Base & Terminals – anchors the switch to the PCB and provides connections

- Actuator or Tape Layer – aids in sealing or switching action

How It Works:

- At rest, the dome is arched and isolated from terminals, keeping the circuit open.

- When pressed, the plunger collapses the dome, making electrical contact.

- Upon release, the dome snaps back, opening the circuit again.

This simple mechanism yields high reliability and long life with low parts count

🔍 Why Tactile Feedback Matters

Tactile and audible feedback (the “click”) ensures the user knows the switch was actuated. This is particularly important in input-heavy scenarios—like typing or pressing remote buttons—where missing a press can cause errors

Compared to traditional push‑buttons, tact switches are optimized for tiny dimensions, short actuation travel, and consistent feedback, making them suited for dense PCB applications

✅ Advantages & Limitations

Pros:

- Responsive tactile experience– physical bump or light click

- Durable, rated for thousands to millions of actuations

- Low-profile and compact design ideal for small devices

- Low voltage/current operation, making them energy-efficient and cost-effective

Cons:

- Not suited for high-current/high-voltage use

- Audible clicks can be disruptive in silent environments

- Environmental sensitivity (dust, moisture) unless sealed variants are used

🧪 Major Types of Tact Switches

1. Standard vs. Sealed

- Standard: open type, no sealing, compact and cost-effective.

- Sealed: includes film or rubber barriers to resist dust and moisture—ideal for harsh environments

2. Mounting Options

- Surface-Mount (SMT) for compact PCBs and automated assembly

- Through-Hole for more robust, mechanical support and manual soldering

- Right-Angle variants for horizontal actuation in space-limited designs

3. Actuation Feel

- Metal Dome: crisp, sharper feedback

- Rubber Dome: softer, quieter feel

Manufacturers tailor dome materials/shapes to tune force, travel, tactile feel, and acoustic response

4. Normally Open vs. Normally Closed

- Normally Open (NO): closes the circuit when pressed

- Normally Closed (NC): opens the circuit when pressed

NC types are available for niche needs where reverse action is desired

🏭 Where Tact Switches Are Used

Tact switches feature across industries and device types:

- Consumer Electronics: remote controls, calculators, handheld devices, gaming controllers

- Computer Keyboards: especially laptop or compact keyboards

- Medical Equipment & Industrial Control Panels: for reliable, tactile input

- Automotive Dashboards: infotainment controls, steering controls, HVAC buttons

- Security Systems & Telecommunications Interfaces: reliable and resilient under frequent use

🛠️ How to Choose the Right Tact Switch

When selecting a tact switch for your design, consider these key parameters:

- Mounting Method: SMT or thru-hole depending on PCB assembly

- Sealing Needs: opt for sealed models for moisture/dust environments

- Actuation Force & Travel: defined in gf and mm; ensure comfort and reliability

- Electrical Specs: voltage/current rating suitable for your circuit

- Feedback Profile: metal vs rubber dome depending on tactile preference

- Life Expectancy: check cycles rating (e.g., 100k to millions)

- Size & Profile: verify overall footprint meets project constraints

- Noise Level: choose quieter switches if user environment is sensitive to clicks

🧠 Quick Comparison Table

| Feature | Typical Specification |

|---|---|

| Action Type | Momentary (press-to-make) |

| Contact Style | Normally Open (NO), optional Normally Closed (NC) |

| Mounting | SMT or Through-Hole / Right-Angle |

| Tactile Feedback | Clicky bump (metal dome) or soft (rubber dome) |

| Actuation Force | ~50–300 gf (application dependent) |

| Travel Distance | ~0.35–0.65 mm or more |

| Voltage / Current | Low-level, signal-level capacities |

| Durability | Tens of thousands to millions of cycles |

| Environmental Protection | IP-rated versions available |

🧠 Design Tips & Best Practices

- Evaluate feel: test switches under real finger pressure for user comfort

- Check datasheets for actuation specs and lifecycle ratings

- Ensure proper soldering: for SMT types, use recommended reflow profiles

- Consider sealing: where moisture or dust may degrade switch life

- Plan for PCB layout: align pads and terminals precisely for thru-hole types

- Noise management: metal domes offer sharper clicks; rubber domes are quieter

✅ Why Tact Switches Still Matter

Despite minimal size and complexity, tact switches continue to be a fundamental choice for accurate, reliable user input across electronics. Their combination of low cost, compact profile, defined actuation, and physical feedback makes them indispensable in user interfaces.

As touchscreens grow, tact switches remain essential where discrete, reliable physical input is needed—like keyboards, instrument panels, industrial controls, and portable gadgets.

🌐 Conclusion

Tact switches balance simplicity and usability, enabling designers to deliver precise, satisfying user input in space-constrained, low-power devices. Understanding their mechanical structure, feedback behavior, and application context ensures the right choice for your next PCB interface design.