Tact & DIP Switch Fundamentals: The Engineer's Guide | HX Switch

In the world of electronics design, the switch is more than just a component—it is the handshake between the user and the machine. Whether it is the satisfying "click" of a consumer interface or the critical configuration logic deep inside an industrial controller, the switch defines the device's reliability and feel.

However, selecting the right electromechanical component is often undervalued. We frequently see high-end PCBs compromised by "mushy" buttons, field failures due to contact oxidation, or assembly rejections caused by improper flux handling.

At HX Switch, we understand that a switch is a precision instrument. This guide explores the electromechanical DNA of Tactile (Tact) and DIP switches, helping engineers and procurement specialists move beyond basic datasheets and make decisions that ensure manufacturing success.

Understanding Tactile (Tact) Switches

A Tactile switch (or "Tact switch") is a momentary action device designed specifically to provide physical feedback to the user. Unlike a standard push-button that might operate silently, a tact switch is engineered to deliver a perceptible "click" or snap.

The Mechanics of the Click

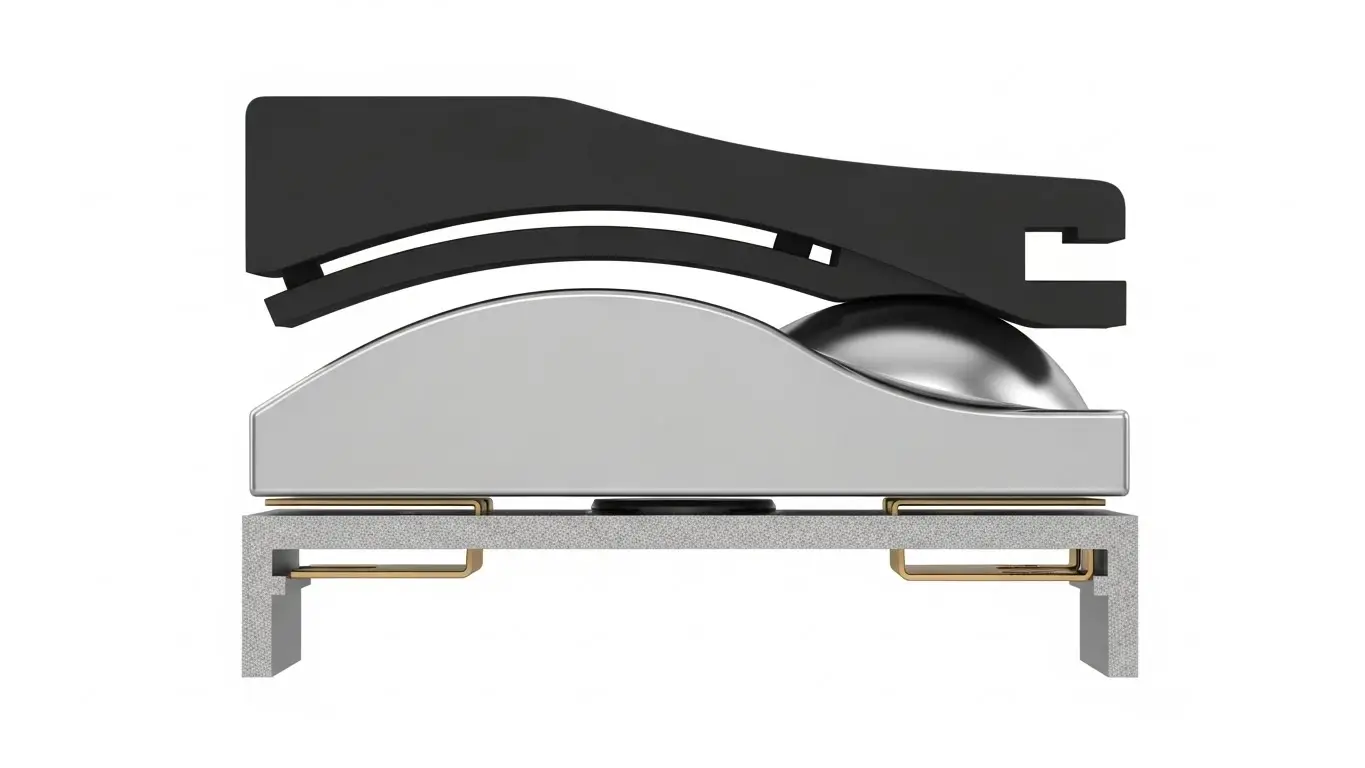

The heart of a tact switch is the metal dome. This is a curved piece of metal (usually phosphor bronze or stainless steel) that sits beneath the actuator.

When you apply force, the dome inverts, closing the circuit between two stationary contacts. Once the pressure is released, the dome snaps back to its original shape, breaking the circuit. This mechanism serves two purposes:

- Electrical: It acts as a Single Pole Single Throw (SPST) normally open switch.

- Haptic: The rapid inversion of the dome creates the crisp physical feedback and audible sound confirming the input.

The "Feel" Factor: Tactile Ratio

Not all clicks are created equal. In our engineering lab, we quantify "feel" using Actuation Force and Tactile Ratio.

- Actuation Force (Operating Force): The amount of pressure required to collapse the dome, typically measured in gram-force (gf). Standard values range from 160gf (soft) to 260gf (firm).

- Tactile Ratio: This is a calculated percentage that defines how "crisp" the switch feels. A higher ratio means a sharper, snappier click. A lower ratio results in a softer, smoother press.

If you are designing a rugged industrial panel, you generally want a high force (260gf+) and high tactile ratio to ensure the operator knows the button was pressed, even while wearing gloves.

Deep Dive into DIP Switches

While tact switches are about user interaction, DIP (Dual In-line Package) switches are about device logic. These are used to customize the behavior of an electronic device for specific situations. They are essentially a series of tiny sliding switches grouped together in a single housing.

DIP switches are typically "set and forget." They are used for setting addresses on a network, configuring remote control frequencies, or selecting operating modes on a motherboard.

Common Types and Applications

Choosing the right form factor depends heavily on your PCB layout and how accessible the switch needs to be.

- Slide Type: The standard configuration. It features raised or recessed actuators that slide ON or OFF. It is robust and immediately readable.

- Piano Type: The actuators are pitched on the side, resembling piano keys. These are excellent for edge-of-board mounting, allowing users to configure the device without opening the enclosure.

- Rotary Type: Instead of sliding levers, you turn a small dial. These are sophisticated switches that output a coded signal (Binary Coded Decimal or Hexadecimal). They are ideal for space-saving designs where you need multiple setting options (like setting a timer delay) in a small footprint.

Critical Specifications for Engineers

When reviewing a specification sheet from HX Switch, three metrics dictate the longevity and reliability of your application.

Contact Rating (Low Power Logic)

It is vital to remember that both Tact and DIP switches are signal switches, not power switches.

- Typical Rating: 50mA @ 12VDC.

- The Risk: Trying to drive a motor or a high-wattage LED directly through these switches will cause arcing, pitting, and immediate failure. They should trigger a controller or transistor, which then handles the heavy load.

Contact Resistance

For low-voltage logic circuits, resistance is the enemy. New switches typically boast a contact resistance of less than 100mΩ.

- Aging: Over time, oxide layers can build up, increasing resistance. If the resistance gets too high, the microcontroller may fail to register the signal "low," leading to intermittent errors.

Life Cycle Differences

This is the most distinct difference between the two families:

- Tact Switches: Built for endurance. Rated for 100,000 to over 1 million cycles.

- DIP Switches: Built for stability. Rated for 2,000 to 5,000 cycles.

Since a DIP switch is usually set once at the factory or during installation, 2,000 cycles are more than sufficient.

Material Science: Gold vs. Silver Contacts

One of the most common questions we receive is: "Should I pay extra for gold plating?"

The answer depends on your environment and electrical load.

Silver (Ag) Clad

- Pros: Excellent conductivity and lower cost.

- Cons: Prone to "sulfurization" (tarnishing) over time if exposed to sulfur gases or high humidity.

- Best For: Standard consumer electronics and general switching.

Gold (Au) Plad

- Pros: Gold does not corrode or oxidize. It remains stable indefinitely.

- Cons: Higher cost.

- Best For: "Dry Circuit" applications. If you are switching extremely low currents (micro-amps) where there isn't enough electrical energy to punch through a thin oxide layer, you must use gold. It is also mandatory for harsh industrial or marine environments.

Assembly & Soldering Best Practices

Even the highest quality switch can be destroyed in seconds on the assembly line. The interaction between the switch housing, the terminals, and the soldering process is critical.

SMT vs. Through-Hole

- Through-Hole (THT): Mechanically stronger. Use this if the switch will be subjected to heavy physical abuse or shear forces.

- Surface Mount (SMT): Ideal for high-density boards. However, you must adhere strictly to the reflow temperature profile (usually a peak of 260°C for extremely short durations).

The Flux Warning

The number one killer of switches during manufacturing is flux wicking. If flux from the soldering process creeps inside the switch housing, it can coat the contact dome. Once this happens, the switch becomes an insulator—it clicks, but no signal passes.

The Solution:

- Unsealed Switches: Should never be washed. Flux must be applied carefully.

- Sealed Switches (IP67): These include a protective membrane or seal (often a Kapton tape or internal O-ring) that allows the board to be washed without contaminating the internal contacts. If your production line involves a full immersion wash, you must specify a sealed switch.

Conclusion

While they share space on the PCB, Tact and DIP switches serve fundamentally different roles. Tact switches are the voice of the user, requiring attention to "feel," actuation force, and high cycle life. DIP switches are the silent logic controllers, requiring stability and clarity of configuration.

For manufacturers, the key to reducing field failures lies in understanding the materials (Gold vs. Silver) and the assembly constraints (Sealed vs. Unsealed).

At HX Switch, we help engineers navigate these choices every day. Whether you need a snappy tact switch for a dashboard or a rotary DIP for a timing circuit, selecting the right component at the design phase saves significant costs in the long run.

FAQ

What is the difference between a Tact switch and a Push button?

A Tact switch is a specific type of momentary push button characterized by a distinct "click" feedback and low current rating (usually <50mA). Standard push buttons may be latching (stay on), can handle higher power, and often lack the sharp tactile click.

What does "DIP" stand for in DIP switch?

DIP stands for Dual In-line Package. This refers to the physical housing of the switch, which has two parallel rows of connecting pins, matching the standard footprint of legacy integrated circuits (chips).

Can I wash Tact switches after soldering?

Only if they are Sealed (IP67 rated). Standard, unsealed tact switches have small openings where washing solvents and dissolved flux can enter, coating the contacts and causing the switch to fail electrically.

Why do my tact switches fail after soldering?

The most common cause is flux contamination. During wave soldering or hand soldering, excess flux wicks up the terminals and enters the switch housing. Heat deformation of the plastic housing due to excessive temperature is the second most common cause.

What is Actuation Force?

Actuation force is the amount of physical pressure (measured in gram-force, gf) required to collapse the switch's internal dome and close the circuit. A higher force (e.g., 260gf) feels stiffer, while a lower force (e.g., 100gf) feels lighter and softer.