How to Select Switches for IoT Devices

Selecting the right electromechanical switches for Internet of Things (IoT) devices requires balancing strict size constraints, energy efficiency, and environmental durability. To ensure optimal performance, you must prioritize components that offer low contact resistance to preserve battery life and compact footprints, such as SMT tactile switches, to fit dense PCBs. Additionally, the operating environment dictates the need for ingress protection; IP67-rated switches are often essential for wearables and outdoor sensors to prevent failure from moisture or dust. Finally, the switch must provide precise actuation force to ensure user confidence without requiring heavy mechanical reinforcement.

Critical Factors in IoT Switch Selection

When designing connected devices, the physical interface is often the only point of physical contact a user has with the hardware. Therefore, the switch choice defines the user experience.

To start, you need to look at the Power Budget. IoT devices often run on coin cells or small rechargeable batteries. A switch with high contact resistance can create unnecessary power loss. You should look for gold-plated contacts which provide reliable low-level switching and resistance to oxidation over time.

Secondly, consider Space Constraints. IoT devices are shrinking. Using bulky components is rarely an option. . This is where understanding the fundamentals of component selection is vital. You can learn more about the basics in our guide on how to choose the right switch for general applications before narrowing down to IoT specifics.

Haptic Feedback and User Experience

Because IoT devices often lack screens or visual indicators, the "click" of a button confirms a command has been sent. This is called haptic feedback. A crisp, tactile feel is preferred for functions like pairing Bluetooth or resetting a device.

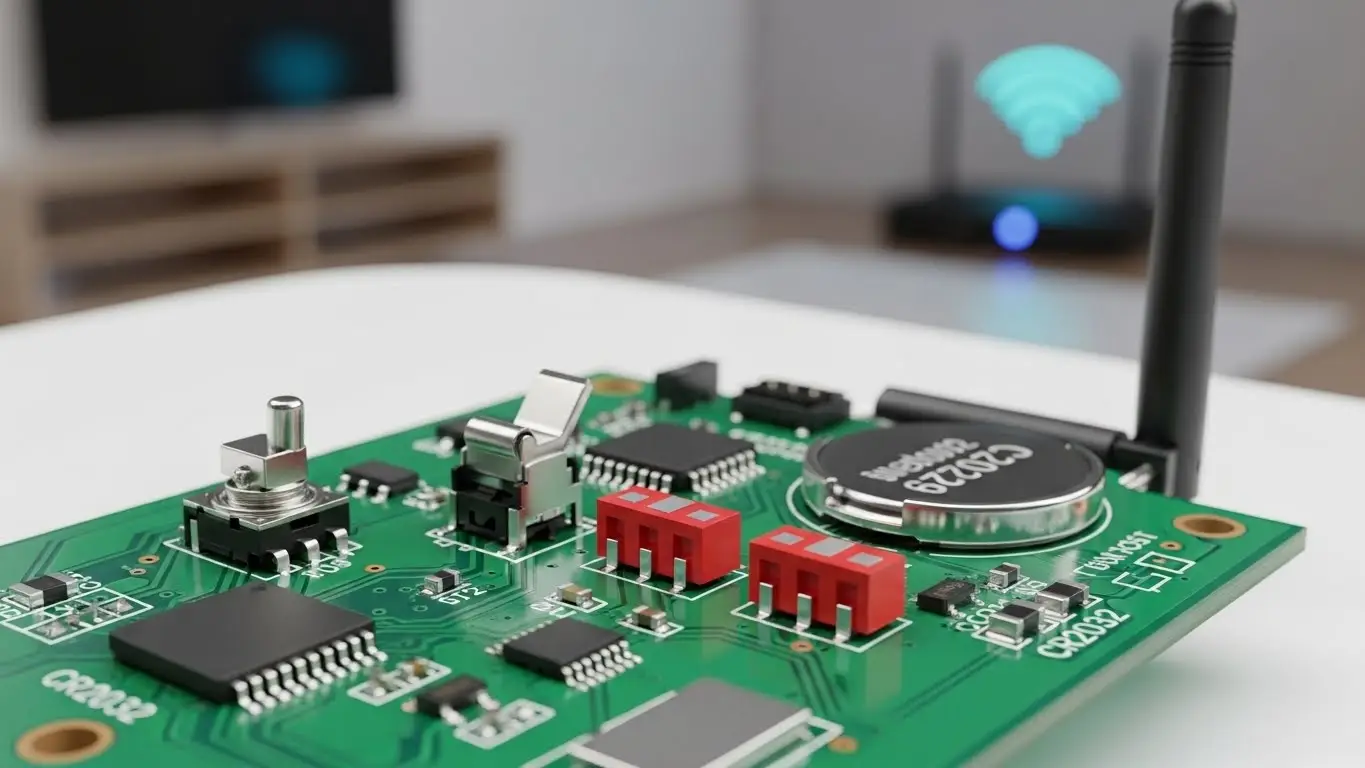

Common Switch Types for Connected Devices

Not all switches serve the same purpose in an IoT ecosystem. The two most common categories are Tactile Switches (for users) and DIP Switches (for configuration).

Tactile Switches for User Interface

Tactile switches are the industry standard for IoT inputs (power, reset, volume, pairing). They are momentary, meaning they are only active while pressed. When selecting these, you must balance the actuation force (how hard you press) with the device's weight. A heavy press on a light wearable device feels awkward. For a deep dive on specific specs, read our guide on how to choose the right tact switch.

DIP Switches for Configuration

For industrial IoT (IIoT) sensors, you often need to set device addresses or toggle specific modes physically before installation. DIP (Dual In-line Package) switches allow you to "set and forget" these configurations. If your PCB layout is tight, you need to know how to choose a DIP switch for PCB design that maximizes space without sacrificing accessibility for the technician.

What IP Rating Do IoT Switches Need?

For most consumer and outdoor IoT devices, an IP67 rating is recommended to ensure the switch withstands temporary submersion and dust ingress.

IoT devices are "in the wild." A smart doorbell, a fitness tracker, or an agricultural sensor will be exposed to rain, sweat, and dirt. If the switch isn't sealed, moisture will corrode the contacts, leading to device failure.

Standard switches are open to the air. Sealed switches utilize internal membranes or O-rings. If you are designing a device for the outdoors or a humid environment (like a smart bathroom fixture), you must review how to select waterproof tact switches.

SMT vs. Through-Hole: Which is Better for IoT?

Surface Mount Technology (SMT) is generally superior for IoT devices because it allows for smaller PCBs and automated pick-and-place assembly.

Through-hole switches are mechanically stronger but take up valuable board space and require holes drilled through the PCB, which limits routing options on multi-layer boards. SMT switches sit on the surface, allowing components to be placed on both sides of the board—a crucial feature for miniaturized IoT tags or sensors.

However, mechanical strength still matters. If the USB port or switch will be abused, through-hole might be necessary. To weigh the manufacturing pros and cons, check our comparison on how to choose SMT vs. Through-Hole DIP switches.

How to Handle High-Traffic Industrial IoT Environments?

Industrial IoT (IIoT) switches require high lifecycle ratings (often 100,000+ cycles) and high temperature resistance to survive factory floor conditions.

Unlike a consumer smart remote that might be pressed a few times a day, an industrial control panel might see hundreds of actuations an hour. Furthermore, IIoT environments often involve vibrations from heavy machinery. A standard consumer switch may experience "contact bounce" or mechanical failure under vibration.

You need switches specifically rated for harsh environments. This involves checking the operating temperature range and vibration resistance. For specific criteria on rugged environments, see how to choose tactile switches for industrial devices.

Comparison: IoT Switch Features by Application

| IoT Application | Recommended Switch Type | Key Feature Priority | IP Rating Needed? |

| Smart Wearable | Ultra-thin SMT Tactile | Low Profile (<2mm height) | Yes (IP67/IP68) |

| Smart Home Hub | Standard Tactile | High Cycle Life | No (IP40 is fine) |

| Asset Tracker | DIP Switch | Reliability (Gold contacts) | Yes (Sealed) |

| Industrial Sensor | Ruggedized Tactile | Vibration Resistance | Yes (IP67) |

Frequently Asked Questions

A: Gold contacts are highly resistant to corrosion and oxidation. Since many IoT devices operate at very low logic voltages/currents (dry circuit), even a small amount of oxidation on silver contacts can block the signal. Gold ensures reliability over long periods of inactivity.

A: Yes, membrane switches are great for sealing a device completely. However, they often lack the sharp "click" (tactile feedback) of a discrete electromechanical switch, which users often prefer for confirmation.

A: Indirectly. A switch with poor tactile feedback might cause a user to press it multiple times or hold it down longer than necessary, keeping the device in a "wake" state longer, which consumes more battery power.

A: Travel is the distance the button moves before it actuates. For IoT wearables, short travel (0.1mm - 0.25mm) is preferred to keep the device compact.

Key Takeaways

- Prioritize Size and Assembly: Use SMT switches to save PCB space and allow for automated manufacturing in mass-produced IoT devices.

- Don't Ignore Environment: Always specify IP67 or higher for wearables, outdoor sensors, or industrial tools.

- User Feedback is Crucial: Choose tactile switches with the right actuation force to give users confidence without needing visual indicators.

- Lifecycle Matters: Match the cycle rating of the switch to the expected lifespan of the product (e.g., 100k cycles for consumer, 1M+ for industrial).

Conclusion

Selecting the right switch for an IoT device is about more than just closing a circuit; it’s about ensuring reliability in a compact, energy-efficient package. Whether you need a waterproof tactile switch for a wearable or a DIP switch for a remote sensor, the right choice prevents field failures and improves user satisfaction.

If you are ready to source high-performance components for your next project, explore our full catalog at HX Switch to find the perfect match for your specifications.