How to Select Waterproof Tact Switches

Select the right waterproof tact switch by evaluating the IP rating (IP67 vs. IP68), actuation force (operating feel), and seal material durability. Prioritize switches with robust contact plating (gold or silver) and validated cycle life to ensure reliability in harsh environments like automotive or medical applications.

What Defines a High-Quality Waterproof Tact Switch?

A high-quality waterproof tact switch features a precise Ingress Protection (IP) rating, durable sealing materials like silicone or elastomer, and consistent actuation force. It must resist moisture, dust, and corrosion while delivering a sharp, tactile "click" throughout its specified lifecycle, often exceeding 100,000 cycles.

When engineering a device for the real world, the definition of "waterproof" is rarely black and white. In my experience troubleshooting field failures for industrial controls, a "waterproof" switch that fails isn't usually leaking water in a bucket test; it's failing due to humidity ingress over months or micro-corrosion on the contacts.

A truly high-quality switch relies on three core pillars:

- Seal Integrity: The method of sealing (e.g., O-ring vs. membrane) determines if the switch can handle high-pressure jets or just accidental splashes.

- Contact Reliability: Even with a perfect seal, condensation can occur. Gold-plated contacts are often necessary for low-current (logic level) applications to prevent oxidation that silver contacts might suffer from.

- Tactile Feedback Stability: A cheap switch loses its "snap" when the rubber dome stiffens in cold weather. A quality switch maintains its force curve across its temperature range.

Key Components of a Waterproof Tact Switch

- The Actuator (Stem): The part you press. Needs to be UV resistant if exposed to sunlight.

- The Dome: Metal or rubber. Provides the tactile feedback.

- The Housing: usually high-temp thermoplastic (like Nylon 6/6) to withstand reflow soldering.

- The Seal: Internal membrane or laser-welded film.

What Do IP Ratings Actually Mean for Tact Switches?

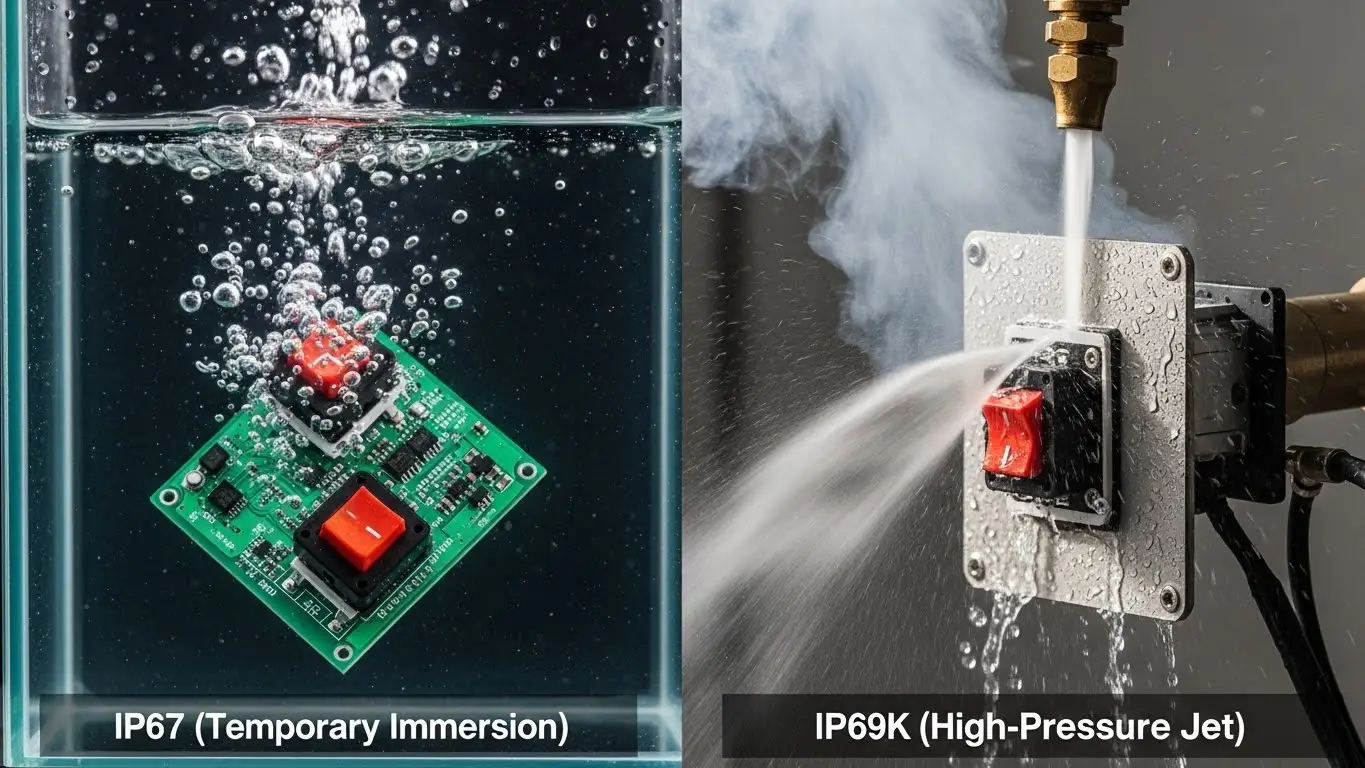

IP ratings indicate protection levels: the first digit (0-6) measures dust resistance, and the second (0-9) measures moisture resistance. For tact switches, IP67 (dust-tight, immersion up to 1m) and IP68 (continuous immersion) are the industry standards for reliable waterproofing.

Understanding Ingress Protection (IP) codes is critical because selecting the wrong one is the most common specification error I see in PCB design.

- IP65: Protected against low-pressure water jets (rain/splashing). Not suitable for submersion. Use this for consumer remotes or kitchen appliances.

- IP67: Protected against immersion up to 1 meter for 30 minutes. This is the "gold standard" for most ruggedized electronics, including handheld GPS units and outdoor sensors.

- IP68: Protected against continuous immersion beyond 1 meter. This is required for marine equipment, dive computers, or devices likely to sit in standing water.

Pro Tip: An IP67 rating does not automatically mean a switch is safe for high-pressure washing (like a car wash). For that, you specifically need an IP69K rating, which resists high-pressure, high-temperature jets.

How Does Operating Force Affect Switch Selection?

Operating force, measured in gram-force (gf) or Newtons (N), determines the tactile "feel" and unintended actuation risk. Heavier forces (260gf+) prevent accidental presses in industrial gear, while lighter forces (100-160gf) suit frequent use in consumer interfaces to reduce user fatigue.

The "feel" of a switch is part of your product's brand identity. A mushy switch feels cheap; a crisp switch feels premium. However, the force isn't just about luxury—it's about function.

| Force Category | Range (gf) | Best Application | User Experience |

| Light Touch | 70gf - 130gf | Keyboards, Data Entry | Fast actuation, low fatigue, potential for accidental presses. |

| Standard | 160gf - 200gf | Consumer Electronics, Home Appliances | Balanced "click," distinct feedback, standard industry preference. |

| Heavy Duty | 260gf - 500gf | Automotive, Industrial Controls | Strong feedback, prevents accidental actuation by vibration or gloves. |

If you are designing a dashboard for a tractor, a 160gf switch will vibrate and "chatter" (false trigger). You need a 300gf+ switch. Conversely, for a medical device keypad used by a technician 500 times a day, a heavy switch will cause repetitive strain.

For a broader understanding of general switch selection, you might find our guide on how to choose the right switch helpful as a baseline before narrowing down to waterproof specifics.

Why Is Seal Material Critical for Longevity?

Seal material dictates chemical resistance and temperature tolerance. Silicone rubber offers excellent flexibility and wide temperature range (-50°C to +200°C), while thermoplastic elastomers (TPE) provide superior chemical resistance against oils and solvents often found in automotive environments.

A waterproof switch is only as good as its seal's chemical compatibility. I once saw a batch of IP67 switches fail in a machine shop not because of water, but because the cutting fluid mist degraded the standard rubber seals, causing them to swell and crack.

- Silicone Seals: Best for outdoor weather resistance (UV and ozone stable). Weak against oils and fuels.

- Nitrile (NBR): Excellent oil resistance but poor UV stability. Good for internal engine components.

- Fluorosilicone: The hybrid choice. Resists both extreme temperatures and aggressive chemicals (fuels/solvents). Expensive but necessary for aerospace applications.

When evaluating these materials, consider the entire lifecycle of the product. If your device will be cleaned with harsh hospital disinfectants, ensure the switch seal material is rated for those specific chemicals.

How to Match Switch Size to PCB Design?

Match switch size to your available PCB real estate and actuation method. Standard sizes like 6x6mm are versatile and widely sourced, while ultra-compact 3x3mm or 4x4mm switches suit high-density wearables but may offer lower cycle life and reduced tactile feedback.

Size constraints often drive the initial selection.

- 6mm x 6mm: The industry workhorse. Massive variety of stem heights and force options. Easy to automate assembly (pick-and-place).

- 12mm x 12mm: Larger surface area allows for bigger internal domes, resulting in a longer lifespan (up to 10 million cycles) and a more distinct "haptic" snap.

- Compact (3mm or 4mm): Essential for hearing aids or smartwatches. Be aware that waterproofing these tiny switches is difficult, and they often carry a price premium for high IP ratings.

If you are currently laying out a board, our specific guide on how to choose a DIP switch for PCB design covers similar spacing and soldering considerations that apply here.

What Are Common Failure Modes for Waterproof Tact Switches?

Common failures include contact oxidation from seal breaches, "stuck" actuators due to debris ingress, and dome fatigue (loss of click). Silver migration between contacts can also occur in high-humidity environments if the switch lacks proper gold plating or sealing.

Knowing how they break helps you choose one that won't.

- The "Squishy" Failure: This happens when the tactile dome cracks or permanently deforms. This is often a sign that the switch was operated with force exceeding its rating (impact load).

- Silver Migration: In humid conditions, silver ions can migrate across the surface of the insulator under DC voltage, creating a short circuit (dendrite growth). Solution: Use gold-plated contacts for any application liable to see high humidity or wetness, even if sealed.

- Vacuum Lock: Sometimes, a perfectly sealed switch works too well. If the air inside heats up (during reflow soldering) and then cools, it can create a vacuum that sucks the button down, keeping it permanently actuated. Solution: Ensure your manufacturer uses a "vented" design that seals after soldering, or strictly follow reflow temperature profiles.

For a deep dive into the nuances of tact technology, refer to our detailed resource on how to choose the right tact switch.

Which Applications Require Specific Certifications?

Medical and automotive applications often require switches meeting specific standards like AEC-Q200 (automotive stress resistance) or ISO 13485 compliance support. Industrial switches may need UL 61058 certification to ensure safety under high electrical loads or flammability requirements.

- Automotive (AEC-Q200): If your switch goes into a car, it must handle thermal shock (-40°C to 125°C) and extreme vibration. Standard IP67 switches will rattle apart.

- Medical (ISO 10993): If the switch surface touches the patient or operator skin, the materials must be biocompatible and non-irritating.

- Fire/Safety (UL 94V-0): The plastic housing must be self-extinguishing. Never overlook this for mains-powered control panels.

Checklist for Final Selection

- Environment: Water, dust, oil, or UV? -> Determines IP Rating & Material.

- User: Gloved hand or bare finger? -> Determines Actuation Force.

- Life: Disposable device or industrial tool? -> Determines Cycle Life (100k vs 1M).

- Assembly: Reflow (SMT) or Hand Solder (THT)? -> Determines Housing Material.

By systematically addressing these questions, you move beyond guessing and start engineering reliability into your product from the very first click.

FAQs (Schema Markup Ready):

IP67 switches are rated for temporary immersion in water (up to 1 meter for 30 minutes), making them suitable for accidental drops. IP68 switches are rated for continuous submersion under conditions specified by the manufacturer, ideal for underwater or marine equipment.

Generally, no. Standard IP67/IP68 switches cannot withstand high-pressure jets. For applications involving pressure washers (like industrial machinery or vehicles), you must select a switch with an IP69K rating to prevent seal breach.

Loss of tactile feedback usually indicates "dome fatigue" or seal failure. If the rubber seal swells due to chemical incompatibility (e.g., oil exposure), it can dampen the movement. Alternatively, mechanical overload can permanently deform the internal metal dome.

Gold contacts are highly recommended for waterproof switches in low-voltage (logic) applications. They resist corrosion and "silver migration" (dendrites) much better than silver contacts, ensuring reliability even if minor condensation forms inside the device.

Extreme cold can stiffen rubber seals, increasing actuation force or causing cracks. High heat can soften plastics or damage the seal adhesion. Always match the switch’s operating temperature range (e.g., -40°C to +85°C) to your specific application environment.