Best DIP Switches for Controller Boards

The best DIP switches for controller boards are typically Surface Mount (SMT) Half-Pitch DIP switches for modern, high-density PCBs, or Piano-style (side-actuated) DIP switches for boards located in accessible enclosures. For industrial controller boards requiring frequent wash-downs or harsh environment protection, tape-sealed slide DIP switches with gold contacts are the industry standard.

Selecting the right switch depends on three specific factors: board real estate (pitch), mounting style, and actuation method. While standard 2.54mm pitch switches are reliable for legacy hardware, 1.27mm half-pitch switches are essential for compact IoT and smart device controllers.

Understanding DIP Switch Types for Controllers

To choose the best component, you must match the actuator style to the controller's physical design.

Slide vs. Piano vs. Rotary

- Slide DIP Switches: The most common type. Low profile and cost-effective. Best for "set and forget" configurations like baud rates or device addresses.

- Piano DIP Switches: Side-actuated (rocker style). These are ideal when the controller board is mounted vertically, or when the switches need to be accessed through a cutout in the device housing.

- Rotary DIP Switches: Allow for selecting a specific value (0-9 or 0-F) using a screwdriver. These are best for complex addressing where you need more than simple On/Off binary options.

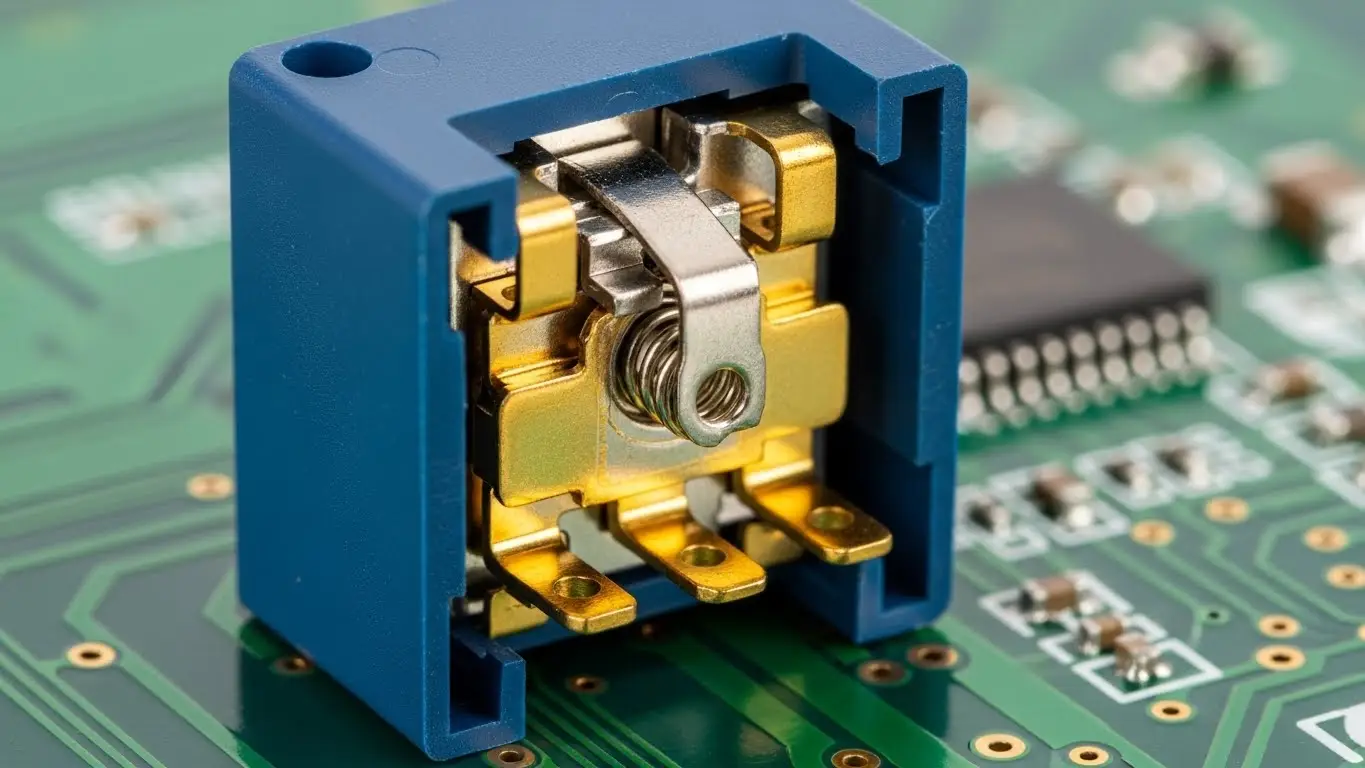

Alt Text: Comparison of Slide, Piano, and Rotary DIP switches mounted on a green controller circuit board.

SMT vs. Through-Hole Mounting

Modern manufacturing generally favors SMT for speed and density, but Through-Hole remains vital for mechanical strength. When designing your board layout, you must decide largely based on your assembly process. For a detailed breakdown on this specific decision, read our guide on how to choose SMT vs. Through-Hole DIP switches.

Comparison of Mounting Styles:

| Feature | SMT (Surface Mount) | Through-Hole |

| Board Space | Minimal (allows components on both sides) | Moderate (takes up space on back) |

| Assembly | Automated Pick & Place | Wave Solder or Manual |

| Mechanical Strength | Moderate | High |

| Best Use Case | IoT Devices, High-Density Boards | Industrial Heavy Machinery, Prototypes |

What is the function of a DIP switch on a circuit board?

A DIP switch is a manual electric switch packaged with others in a standard dual in-line package, used to control signal flow or configure hardware settings.

On a controller board, these switches act as hardware jumpers. They provide a physical way to change the operating mode of a device without software intervention. Common functions include:

- Setting unique device addresses on a network (like RS485 or DMX).

- Configuring baud rates for communication.

- Enabling or disabling specific resistors or circuit paths.

- Putting a board into "test" or "firmware update" mode.

How do I choose the right DIP switch pitch?

Choose a standard 2.54mm pitch for manual prototyping and ease of access, or a 1.27mm half-pitch for space-constrained, machine-assembled production boards.

Space is often at a premium on modern controller boards. If you are designing for the Internet of Things (IoT), miniaturization is key. High-density designs often require components that offer the same functionality in a smaller footprint.

- Full Pitch (2.54mm): Easier to manipulate with fingers; standard for hobbyist and legacy industrial boards.

- Half Pitch (1.27mm): Requires a tool to switch; standard for compact consumer electronics.

For more insights on miniaturized components, check our guide on how to select switches for IoT devices.

Durability and Environmental Protection

Controller boards often sit in unconditioned environments. Dust, moisture, and oxidation are the enemies of reliable signaling.

Sealing Options (Tape vs. Unsealed)

If your controller board undergoes a washing process after soldering to remove flux, you must use a DIP switch with a top tape seal. This prevents contaminants from entering the contact area during production.

For environments that are constantly wet or humid, looking into high IP-rated components is necessary. While DIP switches are rarely IP67 rated once the tape is removed, the logic for selecting sealed components is similar to how to select waterproof tact switches; preventing moisture ingress is critical for long-term reliability.

Contact Material: Gold vs. Tin

- Gold Contacts: Highly recommended for controller boards. Gold resists oxidation and ensures reliability at low logic-level voltages (logic signals).

- Tin Contacts: Cheaper, but better suited for higher current applications where the "wetting" current can break through oxide layers.

Reliability in Industrial Applications

In industrial settings, vibration and temperature fluctuations are common. A cheap switch can accidentally "bounce" or lose contact, causing a controller failure.

When sourcing components for heavy-duty machinery, you need switches tested for shock resistance and extended lifecycles. Just as you would carefully evaluate components when you how to choose tactile switches for industrial devices, you should verify the actuation force and housing rigidity of your DIP switches.

Lifespan Considerations

DIP switches are generally not rated for millions of cycles because they are set infrequently. However, the quality of the contact retention matters. If you require components that handle frequent user interaction, you might want to compare the durability specs against other interface components, such as those discussed in our article on best long lifespan tact switches.

General Selection Checklist

To ensure you cover all bases, use this quick checklist before finalizing your BOM (Bill of Materials):

- Current Rating: Ensure the switch handles the logic level (usually 24V DC, 25mA).

- Actuator Height: Low profile for compact cases, extended for easy access.

- Pole Count: Do you need 4, 8, or 10 positions? Always leave one spare position for future firmware options.

- Cost vs. Quality: For detailed sourcing strategies, refer to our broader guide on how to choose the right switch.

Frequently Asked Questions

o. DIP switches are designed for low voltage and low current (typically signaling logic, 24VDC, 25mA to 100mA). Using them for mains voltage (110V/220V) is dangerous and will destroy the switch.

"Switching rating" refers to the current the switch can handle while being moved. "Non-switching rating" is the current it can carry while in a static position. The non-switching rating is always higher (e.g., 100mA vs 25mA).

Only wash DIP switches that have a factory-installed tape seal. If the switch is unsealed, washing it can trap solvent and flux inside the housing, ruining the contact resistance.

Key Takeaways

- Context Matters: Use SMT Half-Pitch for compact IoT boards and Through-Hole Standard Pitch for industrial prototypes.

- Accessibility: Use Piano (side) switches if the board is mounted vertically or needs edge access.

- Reliability: Always choose gold-plated contacts for low-voltage controller logic to prevent oxidation issues.

- Protection: Ensure switches are tape-sealed if the PCB will undergo a washing process.

Conclusion

Selecting the best DIP switch for your controller board isn't just about the number of poles; it's about matching the mounting style, pitch, and contact material to your specific application environment. By prioritizing gold contacts and the correct form factor, you ensure your controller remains reliable for years to come.