How to Select Tact Switches for Automotive Devices: The Engineering Guide

Selecting tactile switches for automotive applications is fundamentally different from consumer electronics. In a vehicle, a switch isn't just an interface; it is a safety-critical component exposed to thermal shock, constant vibration, and chemical aggressors.

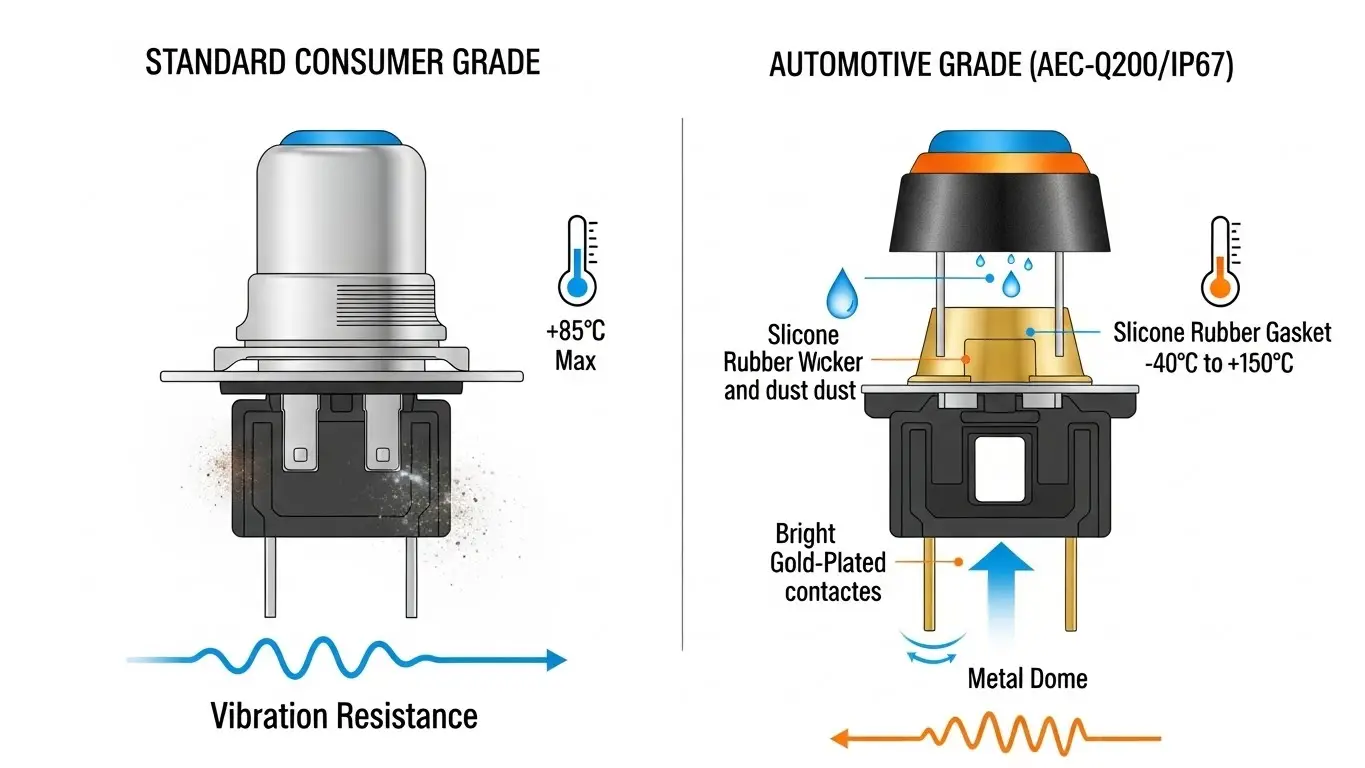

While standard switches prioritize cost and compactness, automotive tact switches must prioritize reliability (AEC-Q200 compliance) and haptic consistency. A switch that fails in a key fob is an annoyance; a switch that fails in an emergency hazard control is a liability.

This guide details the engineering parameters required to select the right electromechanical switches for automotive interfaces, balancing rugged durability with the premium "feel" drivers expect.

1. The Non-Negotiable: AEC-Q200 and Reliability Standards

Before evaluating size or feel, automotive engineers must filter for reliability standards. The baseline for any component on a vehicle PCB is AEC-Q200 compliance.

Understanding Stress Grades

Not all "automotive grade" switches are equal. You must match the switch's temperature grade to its location in the vehicle:

- Grade 0 (-40°C to +150°C): Required for under-hood applications or near engine blocks.

- Grade 1 (-40°C to +125°C): The standard for most dashboard and steering wheel electronics.

- Grade 3 (-40°C to +85°C): Acceptable for cabin electronics that are thermally isolated (e.g., rear-seat entertainment), but often insufficient for dashboard components exposed to direct sunlight.

Note: For a deeper dive into general selection criteria beyond just automotive standards, review our guide onhow to choose the right switch for your project.

2. Environmental Resilience: "The Automotive Factor"

Vehicles are hostile environments. Your switch selection must account for three primary environmental aggressors.

Vibration and Contact Fretting

Unlike stationary industrial devices, vehicles are in constant motion. Low-frequency vibration from the road and high-frequency vibration from the engine can cause "fretting corrosion" on switch contacts.

- Solution: For high-vibration zones (steering wheels, gear shifters), specify switches with high contact force or sliding contact mechanisms that "wipe" the surface clean with every actuation.

Moisture and Chemical Ingress (IP Rating)

Cabin spills, humidity, and condensation are inevitable.

- IP67 Rating: Essential for center console switches (prone to coffee spills) and door controls (exposed to rain).

- Silver Migration: In high-humidity environments, silver contacts can suffer from electromigration, causing short circuits. For critical applications, consider gold-plated contacts to prevent corrosion and migration.

Thermal Shock

A car parked in winter can go from -20°C to +25°C in minutes when the heater starts. Your switch must withstand this rapid expansion and contraction without cracking the housing or delaminating the dome.

3. Haptics: The "Feel" of Quality

Once reliability is secured, the focus shifts to the driver's experience. In automotive design, the "click" conveys quality. A mushy switch feels "cheap," while a crisp, sharp click feels "premium."

The Force-Travel Ratio

- Short Travel (0.15mm - 0.3mm): distinct "clicky" feel. Preferred for steering wheel controls where the driver needs immediate confirmation without looking.

- Long Travel (0.5mm+): Softer, rubbery feel. Often used in dashboard buttons to prevent accidental actuation.

Haptic Consistency

A major challenge in automotive design is maintaining the same "feel" across temperatures. Cheaper silicone actuators stiffen in the cold, making the button hard to press in winter.

- Recommendation: Use switches with high-quality metal domes or specially formulated silicone that maintains consistent elasticity from -40°C to +85°C.

For more on selecting switches for connected/smart vehicle modules, see our guide on selecting switches for IoT devices.

4. Lifespan: Matching Cycles to Usage

Not every button needs a million cycles. Over-specifying drives up costs, while under-specifying leads to warranty claims.

| Application | Required Cycles | Why? |

| Turn Signals / Audio Volume | 300k - 1M+ | High-frequency daily use. Requires long lifespan tact switches. |

| Hazard Lights | 50k - 100k | Infrequent use, but must work perfectly after years of dormancy. |

| Seat Memory Set | 30k - 50k | Low frequency; primarily "set and forget." |

5. The Ecosystem: PCB Configuration & Settings

While the tactile switch is the user interface, the automotive Electronic Control Unit (ECU) often requires internal configuration switches for factory settings, regional coding, or diagnostics.

- Controller Boards: Designers often use DIP switches to set initial parameters (e.g., selecting between "sedan" or "SUV" firmware profiles on a universal ECU). Learn more about DIP switches for controller boards here.

- Network Configuration: For telematic units handling Wi-Fi or LTE settings, internal switching may be required during the assembly process. See how to choose DIP switches for router and network settings.

Frequently Asked Questions

Automotive grade switches typically undergo stricter testing (AEC-Q200) for thermal shock, vibration resistance, and solvent resistance. They often feature higher operating temperature ranges and robust silver/gold plating to prevent failure in harsh conditions.

Silver offers lower electrical resistance and is cheaper, making it standard for most signal currents (12V). However, for low-power logic circuits (5V or 3.3V) or high-sulfur environments, Gold is recommended because it does not tarnish or corrode, ensuring signal integrity over the vehicle's 10+ year life.

Luxury vehicle manufacturers often specify "soft sound" switches (using rubber actuators) to reduce cabin noise and create a refined atmosphere. Sports cars or utility vehicles may prefer "crisp sound" (metal actuators) to provide clear, audible feedback that the action was registered.

Automotive switches often use higher actuation forces (300gf - 500gf) compared to consumer electronics (160gf). This prevents accidental presses caused by road vibration or the weight of the driver's hand resting on the controls.

Key Takeaways

- Prioritize Standards: Ensure your switch meets AEC-Q200 guidelines and the correct temperature grade for its location in the vehicle.

- Match the Haptics: Use "Crisp/Short Travel" for blind-operation controls (steering wheel) and "Soft/Long Travel" for comfort controls.

- Watch the Environment: Use IP67 switches for areas exposed to spills or moisture and consider gold contacts to prevent corrosion.

- Plan the Whole PCB: Don't forget internal configuration components like DIP switches for ECU setups.

Conclusion

Selecting the right tact switch for automotive devices is a balancing act between rugged reliability and refined user experience. By focusing on the "Three H's"—Hardness (Durability/IP Rating), Heat (Temperature Grade), and Haptics (User Feel)—engineers can specify components that survive the life of the vehicle while providing the premium interaction drivers demand.