When to Use Rotary Switches Instead of DIP Switches: A Practical Guide

You should use rotary coded switches instead of DIP switches whenever end-user convenience and error reduction are your top priorities. While DIP switches are cost-effective for permanent factory settings, rotary switches are superior for field-adjustable settings—such as assigning device addresses or IDs—because they are human-readable (0-9) and do not require binary calculation. Choose a rotary switch if your device requires frequent reconfiguration, is used in low-light environments, or needs to be operated by technicians without specialized tools. They bridge the gap between complex binary logic and simple user interface.

Why Choose Rotary Switches Over Standard DIPs?

The primary reason engineers upgrade from standard Dual In-line Package (DIP) switches to rotary switches is usability.

A standard DIP switch represents raw binary code. To set a device ID to "5," a technician needs to know that "5" equals 0101 in binary and must flip switches 1 and 3 to "On" and 2 and 4 to "Off." This process is prone to human error.

In contrast, a rotary coded switch handles the translation mechanically. The user simply turns the dial to the number "5," and the internal contacts output the correct binary signal to the circuit board. If you are exploring broader component replacements, you might also find our guide on the best alternatives to DIP switches helpful for a wider range of options.

What are the Main Advantages of Rotary Switches?

Ease of Use and Speed

Rotary switches reduce configuration time by eliminating binary math.

When a field technician is installing 50 sensors in a factory, turning a dial to "1," "2," and "3" is significantly faster than referencing a manual to figure out the DIP patterns for those numbers. This "Real Code" or "Complement Code" output is handled entirely inside the switch housing.

Environmental Sealing

Rotary switches are generally easier to seal against dust and moisture.

Because of their internal construction (O-rings on the rotor), many rotary switches come with IP67 ratings as a standard or low-cost option. Standard "piano" style DIP switches are harder to seal effectively without using protective tape that must be peeled off after washing, which adds a step to manufacturing.

Are Rotary Switches More Expensive Than DIP Switches?

Yes, rotary switches typically cost 2x to 4x more than standard DIP switches.

Because they contain more complex internal mechanical parts (a rotor, wiper contacts, and a housing), the manufacturing cost is higher.

However, you must calculate the Total Cost of Ownership (TCO). If a technician spends an extra 10 minutes troubleshooting a device because they flipped the wrong DIP switch, that labor cost far exceeds the $0.50 saved on the component. Use rotary switches on high-value equipment where reliability is paramount.

How Does Space Constraint Affect the Choice?

DIP switches are often flatter, but rotary switches are more footprint-efficient for data density.

A single rotary switch (roughly 10mm x 10mm) can provide 16 distinct positions (0-F, Hexadecimal). To get 16 positions on a DIP switch, you need a 4-position block. While the footprint is similar, the rotary switch is often taller.

If your device is incredibly thin—like a wearable or a credit-card-sized tracker—the height of a rotary switch might be a dealbreaker. In those extreme cases, you might look at alternatives to tact switches in compact devices to see how designers minimize vertical profiles using membrane or capacitive tech.

Comparison Table: DIP vs. Rotary

| Feature | DIP Switch | Rotary Coded Switch |

| User Interface | Binary (Requires calculation) | Decimal/Hex (Human readable) |

| Cost | Low | Medium/High |

| Profile (Height) | Very Low | Medium |

| Sealing (IP Rating) | Low (usually IP40) | High (often IP67) |

| Best Use Case | "Set and Forget" Factory Settings | Field Address/ID Selection |

Can Rotary Switches Be Used for Networking Hardware?

Yes, rotary switches are the industry standard for setting hardware addresses on legacy industrial networks.

Protocols like Modbus, PROFIBUS, and older CAN bus systems frequently use rotary dials to set the "Node ID." However, modern Ethernet-based systems are moving away from physical switches entirely.

In advanced setups, configuration is often handled via software or web servers, eliminating the need for physical interaction. This trend mimics the shift seen in network infrastructure, where managed software is replacing unmanaged hardware. You can learn more about this transition in our article on industrial Ethernet switch alternatives.

Frequently Asked Questions

Most PCB-mounted rotary switches have a slot for a small screwdriver. However, some models feature extended shafts or thumbwheels that allow for adjustment by hand, which is ideal for frequent changes.

Real Code outputs a standard binary signal (e.g., Position 1 = High). Complement Code outputs the inverse (e.g., Position 1 = Low). The choice depends on your microcontroller's logic requirements.

Yes, rotary switches are generally very stable. The detent mechanism (the "click" you feel) is designed to hold the rotor in place, preventing the setting from drifting even under vibration.

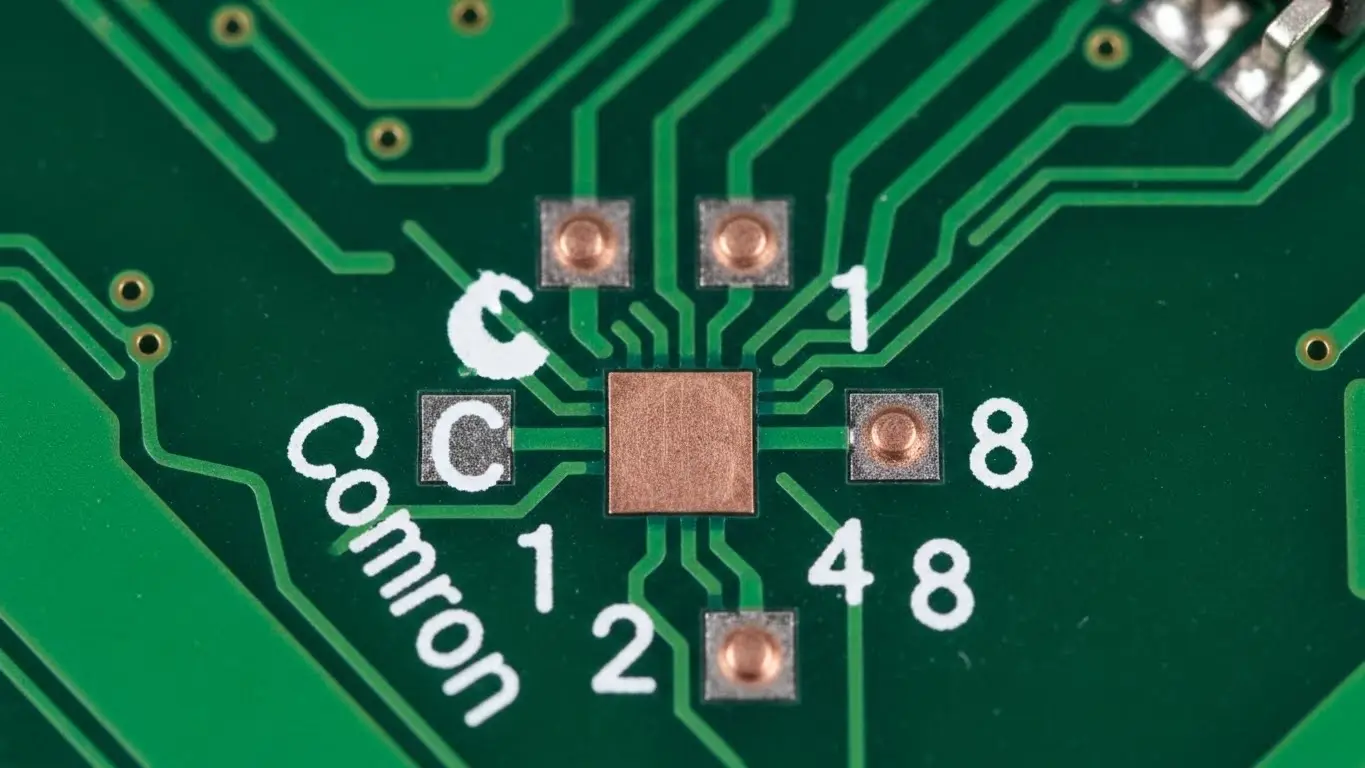

Not directly without a redesign. The pin footprint is different. A DIP switch uses two rows of pins (2.54mm pitch), while a rotary switch typically uses a specific pattern of 4 to 6 pins depending on the coding (1-2-4-8-Common).

Key Takeaways

- User Experience: Use rotary switches when humans need to change settings; they are intuitive and reduce errors.

- Cost vs. Value: Rotary switches cost more but save money on technical support and installation time.

- Environment: Choose rotary switches for harsh environments due to better sealing options (IP67).

- Data: Use rotary switches for setting IDs (0-9 or 0-F); use DIP switches for toggling independent features (On/Off).

Conclusion

Deciding when to use rotary switches instead of DIP switches comes down to who will be touching the device. If it is a factory robot setting configured once, save money with a DIP switch. If it is a field device adjusted by a technician in the rain, the rotary switch is the only professional choice.