Reliable Wafer Connector: Ensuring Secure PCB Connections

What Is a Wafer Connector?

A wafer connector serves the purpose of an electronic connector which integrates the components of an electronic device, usually between a printed circuit board (PCB) and wires or between two PCBs. Each connector has a plastic sleeve containing several metallic contacts. Their small size, high efficiency, and effortless installation make them very popular.

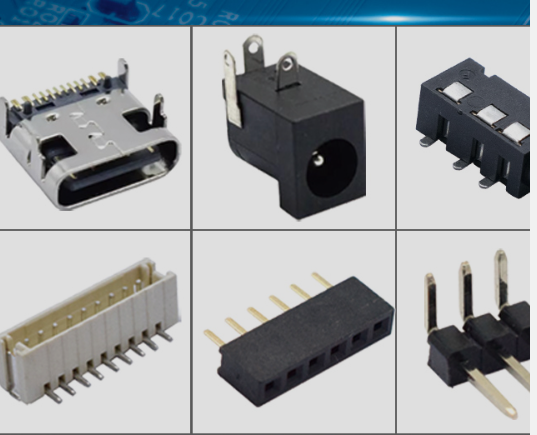

Wafer connectors in particular include:

• Wire-to-board connectors (for connecting wires to PCBs)

• Board-to-board connectors (for connecting two PCBs directly)

Because of their small dimensions, low profile, and dependable interconnects, connectors can be found nearly everywhere, including smartphones and industrial robots.

Why Are Wafer Connectors So Popular?

Compact & Space-Saving

For today's technology, which is continuously getting smaller, these connectors allow designers to conserve the limited space on PCBs in the form of low profile and mini size.

High-Density Connections

If many contacts are required in a confined space, these connectors are the perfect solution, as they provide single-row, double-row, or even multi-row options.

Reliability and Security

These types of connectors grant secure interconnections between PCBs and guarantee stability in power supply and signals in harsh environments.

Versatile Mounting Options

No matter if you prefer a sleek surface mount or a robust through-hole, there’s a connector for you.

Wafer Connectors: Annotated Applications

These connectors are multifunctional warriors for the following applications:

•Consumer Electronics: Smartphones, tablets, laptops

•Industrial Equipment: Automation machines, robotics

•Automotive Systems: Dash Sensors and Dashboard Display Units

•Medical Devices: Diagnostics monitors

•Telecommunications: Networking Equipment and Servers

In these industries, power and signal connectors rely on premium performance from wafer connectors.

Choosing the Best Connectors

While picking a wafer connector may not take rocket science, it does require gentle guidance:

Step 1: Understand Your Application

Is it for a signal? Power? Or both? Each connector has a unique power voltage and current limit.

Step 2: Pin Count

A two-pin connector has a single function. For advanced systems, you might need multi-row or 10-pin connectors.

Step 3: Your Mounting Style

• SMT offers compact designs.

• Through-hole connectors are stronger

Step 4: Check for the Pitch

A connector’s space and size are determined by the pitch. The most commonly used pitch is 2.54mm while the smaller the pitch, the more confined connections get in less space.

Step 5: Material Quality

Longer life and better performance are offered through high-quality plastic housing and metal clips.

Tips for Installing a Wafer Connector

The installation of a connector becomes simple after undergoing the following steps:

PCB Preparation— Ensure the board is clean, and the solder pads are prepped.

Correct Placement of Connector – Make certain the connector is exactly where it needs to be placed on the board.

Pin Soldering – For Through-Hole, insert and solder. For SMT, apply solder paste and reflow.

Housing Securement – Ensure that the connector housing is taut.

Why Choose Hanxia Over Other Vendors?

Strong Partnerships and Modern Innovations

The company Hanxia partners with top Korean companies for technical collaboration to foster innovation.

- This allows them to respond to changes in the market while offering the best quality possible.

- By restricting certified premium raw materials, they ensure the performance and longevity of the products guarantees.

- Regarding their technology objectives, the company says that they have fully automated assembly lines.

- With this, the risk of human errors is dramatically lowered, which leads to stable and dependable quality for every batch of products.

Industry Leading Quality Control

Hanxia set up automated inspection and functional testing of all products, which the company utilizes for quality control and assurance.

- Each connector undergoes quality inspection before it can reach our customers.

- Defect-free, high-performance connectors are what leave our factories.

- It makes us proud that every one of our products follows international certification regulations such as CE, REACH, and ROHS 2.0.

- Moreover, we hold the ISO 9001 certification, which is awarded for global quality management.

Diverse Custom Solutions and a Versatile Product Range

Asda Global Hanxia is known for its patented and copyrighted wafer connectors meeting the requirements for broad applications. We serve all sorts of business clients, whether they are looking for standard models or require intricate technical modifications. Clients who present us with custom requirements greatly benefit from our impressive capabilities in R&D, as we are able to tailor perfectly fitting solutions.

- Fast delivery, high precision, and consistent efficiency are guaranteed by our daily throughput of more than 2 million units, thanks to our 38 automated production lines. Primary Industry Hanxia Dominates Hanxia Define the flexibility Hexiang holds as cross-design landing whole industry.

- Unlimited technologies have granted Hanxia absolute power over the semiconductor manufacturing industry.

- Hanxia stays miles ahead of every other company in the market because of its unmatched performance across the board.

- Exceptional Quality and Effective R&D combined with agile innovation result in indefatigable hand-design-driven enhancements of engineering layouts in production molds.

Professional Quality Management System

Hanxia follows all procedures within a rigid quality management system, to the deal level ensuring each step from design to delivery is compliant with ISO 9001 standards.

Expert Product Selection Guide

Selecting the correct wafer connector is effortless when doing business with Hanxia.

This is an overview of some of the numerous benefits wafer connectors will bring:

- Connectors that save space on a board

- Dependable connections between boards and wires

- Simple installation and repair

- Cost-effective for production in large quantities

- Flexible to fit any purpose

The connectors serve as a vital resource from PCB prototyping to mass production.

Conclusion

In the fast-evolving electronic industry, wafer connectors are miniature life savers that ease the connectivity of circuits, wires, and devices serving as a pathway. With single-row connectors, IDC connectors, SMT board-to-wire connectors, and right-angle PCB headers, there is a manifold of wafer connectors available to aid bring life to your project. Pcb, signal troubleshooting, or solving space constraint challenges all become achievable with the help of wafer connectors. So, the next time you catch a glimpse of the new sparkling gadget or a state-of-the-art industrial robot, don’t forget—somewhere in the background, a tiny wafer connector is laboring diligently!