Technical Use Cases & Application Notes

Engineering reliability isn't just about whether a component works on a datasheet; it’s about whether it survives the field. Field failure analysis consistently shows that 80% of switch malfunctions stem not from manufacturing defects, but from selecting the wrong technology for the specific environmental stress. A standard IP65 mechanical switch might pass initial testing in a food processing plant, but it will almost certainly fail within months when subjected to daily high-pressure caustic washdowns.

At HX-Switch, we move beyond simple industry listings to explore the physics of protection. Understanding why a specific switch technology—Piezo, Capacitive, or Anti-Vandal—is required for a specific application is the difference between a machine that runs for ten years and one that creates costly unplanned downtime.

Critical Environments: The Physics of Protection

The most common specification error we see in industrial design is the misunderstanding of Ingress Protection (IP) and Impact Protection (IK) ratings. These are not merely marketing numbers; they represent specific testing thresholds that dictate survival.

IP67 vs. IP69K: The Washdown Difference

Many engineers default to IP67 (immersion up to 1 meter) assuming it covers all "wet" applications. However, IP67 does not guarantee protection against high-pressure jets.

- IP67 (Immersion): Designed for temporary submersion. The seals are tested against static pressure.

- IP69K (High-Pressure/Steam): Designed specifically for washdowns. The "9K" rating involves testing with water jets at 80°C (176°F) and pressures up to 100 bar (1450 psi).

For industries like food and beverage or pharmaceuticals, where sanitation crews use high-pressure heated water, an IP67 switch will eventually leak. The static seals often cannot withstand the dynamic force of the jet, leading to water ingress and short circuits. In these environments, specifying IP69K is not optional—it is a functional necessity.

IK10 Impact Resistance

In public access areas, durability is measured in Joules. The IK rating system classifies protection against external mechanical impacts. An IK10 rating means the switch can withstand 20 Joules of impact energy—roughly equivalent to dropping a 5kg mass from 400mm directly onto the actuator. This level of protection is critical for unsupervised kiosks, ATMs, and ticket machines where vandalism is a constant risk.

Use Case 1: Food & Beverage Processing

The Challenge: Hygiene and Contamination Food processing machinery faces a dual threat: the aggressive chemical agents used for cleaning (chlorides, acids) and the strict requirement to prevent bacterial growth. Standard mechanical switches often have crevices around the actuator where organic matter can accumulate, creating a biohazard risk (Listeria/Salmonella).

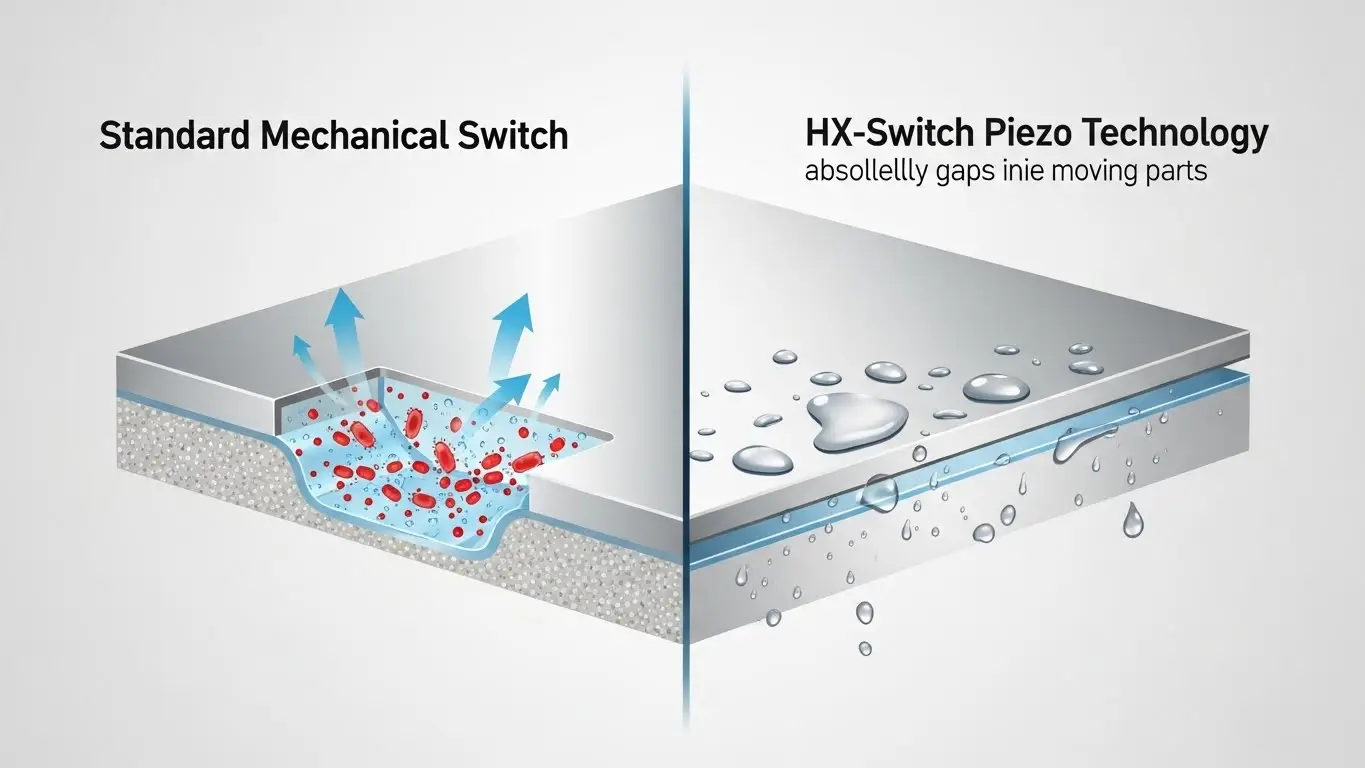

The Technical Solution: Solid-State Piezo Technology For these applications, we recommend Piezo switches. Unlike mechanical switches, Piezo technology has no moving parts. The switch surface is a single, continuous piece of metal that deforms microscopically (microns) to register a press.

- Zero Crevices: The one-piece construction eliminates the gap between the button and the bezel, removing any hiding spot for bacteria.

- Chemical Resistance: When machined from 316L Stainless Steel, these switches resist the corrosive effects of chlorine-based sanitizers that would pit lower-grade 304 steel.

- Operational Life: With no moving parts to wear out, these switches are rated for 50 million cycles, far exceeding the lifespan of mechanical alternatives in high-use production lines.

Use Case 2: Marine & Naval Applications

The Challenge: Galvanic Corrosion and Salt Fog Marine environments are arguably the most corrosive for electromechanical components. The combination of saltwater (an electrolyte), humidity, and dissimilar metals creates the perfect conditions for galvanic corrosion. Furthermore, operators often wear thick neoprene gloves, making standard capacitive touchscreens unreliable.

The Technical Solution: 316L Stainless Steel & Sealed PCBs For marine dashboards and deck controls, material selection is paramount.

- 304 vs. 316L: While 304 stainless steel is adequate for kitchens, it lacks Molybdenum. 316L stainless steel contains 2-3% Molybdenum, which drastically increases resistance to pitting corrosion from chloride ions found in seawater.

- Sealing: We utilize fully potted backs, where the PCB and wiring connections are encapsulated in epoxy resin. This prevents salt fog from reaching the contacts, which causes "fretting corrosion"—a common failure mode where microscopic oxidation builds up on contacts, eventually breaking the circuit.

Note: For systems requiring complex data routing alongside physical actuation in these environments, engineers should also consider exploringindustrial Ethernet switch alternativesthat match these rugged specifications.

Use Case 3: Public Access & Kiosks

The Challenge: Vandalism and Weather Ticket machines, EV charging stations, and public information kiosks are subject to abuse, intentional jamming, and exposure to rain and freezing temperatures.

The Technical Solution: Anti-Vandal Mechanisms Our Anti-Vandal series is designed with three specific defensive features:

- Flush Actuators: The button profile is flush with the bezel, making it nearly impossible to jam a screwdriver or knife under the actuator to pry it off.

- Rear Mounting: The switch is secured from behind the panel. There are no visible screws or mounting nuts on the front, preventing unauthorized removal.

- Short-Body Design: Modern kiosks often have limited depth behind the panel. We offer short-body mechanical switches that provide the necessary IK10 protection while fitting into tight enclosures.

Use Case 4: Industrial Automation & CNC Controls

The Challenge: Vibration and Oil Exposure CNC machines and industrial automation lines subject components to constant vibration (which can cause contact bounce) and exposure to cutting fluids and oils.

The Technical Solution: Momentary vs. Latching Logic In automation, the choice between momentary and latching functions is a critical safety decision.

- Momentary (Non-Locking): Used for "Start" and "Jog" functions. The circuit is active only while the operator presses the switch. This is safer for machine control, ensuring the machine doesn't unexpectedly restart after a power outage (a risk with latching switches).

- Latching (Locking): typically reserved for specific power modes or "Emergency Stop" circuits where the state must be maintained until manually reset.

To combat vibration, our industrial switches utilize high-tension internal springs or solid-state piezo elements to prevent "contact bounce"—a phenomenon where the switch contacts physically bounce apart for milliseconds during actuation, causing false signals in high-speed PLC inputs.

Medical & Laboratory Equipment

The Challenge: EMI and Sterilization Medical environments require devices that are easy to sterilize and do not emit or react to Electromagnetic Interference (EMI), which can disrupt sensitive monitoring equipment.

The Technical Solution: Non-Magnetic Materials & Low Voltage For MRI rooms and sensitive labs, we supply switches made from non-magnetic materials (such as anodized aluminum or specific plastics) to avoid magnetic field interference. Furthermore, our switches are compatible with low-voltage logic (3.3V / 5V / 12V / 24V), integrating seamlessly with modern medical microcontrollers without requiring high-voltage relay intermediates.

Conclusion

The reliability of an industrial machine is often defined by its weakest component. By matching the switch technology—specifically its material, IP rating, and actuation method—to the environmental physics, engineers can virtually eliminate switch-related failures.

Whether you need the hygiene of a Piezo switch for food processing or the brute strength of an IK10 Anti-Vandal switch for a public kiosk, the key is understanding the application notes behind the spec sheet.

Ready to optimize your panel design? Consult with the HX-Switch engineering team to review your environmental requirements and select the exact switching solution for your build.

FAQ

A momentary switch is active only while you are pressing it (like a doorbell or a keyboard key). It returns to its default state immediately upon release. A latching switch stays in its new state after being pressed (like a light switch) and requires a second press to return to the original state. Momentary switches are generally safer for industrial machine "Start" buttons to prevent accidental restarts.

Choose Piezo switches when you need extreme durability (millions of cycles), absolute water/dust sealing (up to IP69K), or vandal resistance. Because they have no moving parts, they are immune to wear and jamming. However, if you need a "click" feeling (tactile feedback) or are switching high currents directly, a mechanical switch might be a better fit.

Yes. To simplify your manufacturing process, we can provide switches with pre-attached wiring harnesses and connectors. This "Plug & Play" approach reduces assembly time and eliminates the risk of soldering errors on your production line.

IK10 is the highest standard rating for impact protection. It certifies that the switch can withstand a 20-joule impact without breaking. In practical terms, this means the switch will survive a significant blow from a heavy object, such as a hammer or a dropped tool, making it ideal for unsupervised public areas.

If the installation is near the ocean or in a snowy area where roads are salted, yes. Standard 304 stainless steel will develop "tea staining" (surface rust) in salty environments. 316L contains Molybdenum, which resists this corrosion. For general outdoor use away from salt, 304 stainless steel or anodized aluminum is often sufficient.