Tactile Switches for Medical Equipment: Design, Safety & Selection Guide

Tactile switches for medical equipment are specialized electromechanical components engineered to deliver precise user input, high reliability, and resistance to harsh sanitation protocols. Unlike standard switches, medical-grade tact switches must meet rigorous safety standards (such as IEC 60601), withstand frequent sterilization via chemicals or autoclaving, and provide unmistakable haptic feedback through surgical gloves. They serve as the critical interface for life-sustaining devices like ventilators, infusion pumps, and defibrillators, where a failure to register a command can have life-threatening consequences.

What Standards Define Medical-Grade Tactile Switches?

Medical-grade switches are defined by their ability to maintain electrical integrity under frequent cleaning, high usage cycles, and stringent regulatory compliance.

When designing for the medical sector, off-the-shelf components often fail to meet the necessary durability requirements. A medical tact switch must typically offer an IP67 or IP68 rating, ensuring the internal contact dome is hermetically sealed against the ingress of fluids, biological contaminants, and aggressive cleaning agents like isopropyl alcohol or bleach.

Additionally, these switches often require gold-plated contacts to prevent oxidation and ensure reliable low-current switching (logic level) over a lifespan that can exceed 1 million cycles. For engineers, understanding the testing protocols for these standards is vital. You can find deeper insights into testing and validation in our technical switch application notes.

Why Is Haptic Feedback Critical in Medical Devices?

Haptic feedback—the physical "click" felt upon pressing—is a non-negotiable safety feature that confirms actuation without requiring the user to look at the device.

In a high-stress operating room or emergency vehicle, medical professionals rely on muscle memory. They often cannot divert their eyes from the patient to check a screen. A tact switch with a sharp "snap" ratio (high tactile ratio) provides physical confirmation that a drug dose has been adjusted or a mode has been changed.

Furthermore, medical staff frequently wear latex or nitrile gloves, which dull sensitivity. A standard consumer switch with a light actuation force (e.g., 100gf) might not be felt through a glove. Therefore, medical switches often utilize higher actuation forces (250gf to 400gf) to ensure the user feels the collapse of the dome.

Can Tact Switches Withstand Medical Sterilization?

Yes, but only if they are specifically specified with sealed housings and chemically resistant materials.

A standard tact switch will fail if exposed to saline or sterilization fluids; the liquid will wick into the switch and corrode the contacts. Medical switches combat this with:

- Silicone or Rubber Actuators: These provide a continuous seal through the device panel.

- Laser-Welded Housings: Eliminating gaps where fluid could enter.

- Membrane Overlays: Often, tact switches are placed behind a sealed graphic overlay to provide a completely flat, wipeable surface.

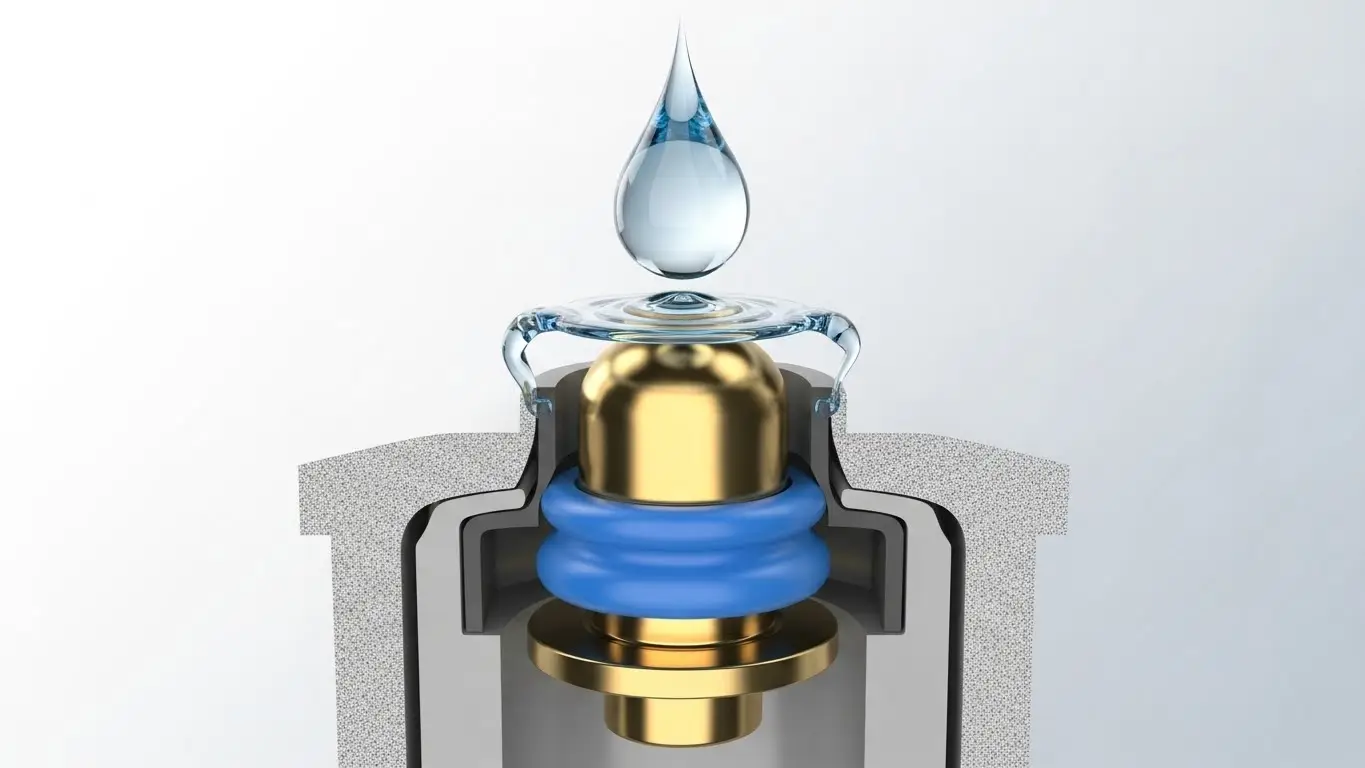

Image Suggestion:

Description: A close-up cross-section of a sealed tact switch showing the internal rubber gasket and gold contacts, protecting it from a droplet of water.

Alt Text: Cross-section of IP67 sealed tactile switch resisting liquid ingress for medical safety.

How Do Medical Tact Switches Differ from Consumer Versions?

The primary differences lie in the operating life, failure rate tolerances, and environmental sealing.

While a remote control uses a switch designed for cost-efficiency, a dialysis machine requires a switch designed for zero-failure tolerance.

- Consumer Switches: Focus on compact size and low cost. Often rated for 100k cycles.

- Medical Switches: Focus on redundancy and robustness. Rated for 1M+ cycles and often use silver-palladium or gold contacts.

For a detailed look at the consumer side of design to understand the contrast, refer to our guide on tact switches for consumer electronics.

Comparison: Tact Switches vs. Other Medical Interfaces

| Feature | Tactile Switch | Membrane Switch | Capacitive Touch |

| Feedback | High (Physical Snap) | Low/Medium | None (Requires Audio/Vibration) |

| Glove Usage | Excellent | Good | Poor (Requires specialized gloves) |

| Cleaning | Good (with overlay) | Excellent (Flat surface) | Excellent (Flat surface) |

| Cost | Low | Medium | High |

| Reliability | High (Mechanical) | Medium | High (Solid State) |

While tact switches handle the dynamic user inputs, other switches handle configuration. For example, DIP switches for industrial machines and medical equipment are often used on the internal PCB to hard-code device addresses or calibration modes that doctors do not need to access.

What Are the Best Actuation Forces for Medical Applications?

The ideal actuation force for medical devices typically ranges between 260gf and 400gf to prevent accidental presses and ensure detection through gloves.

Selecting the wrong force is a common design error.

- Low Force (<160gf): Too light. Risk of accidental activation if brushed against. Hard to feel through gloves.

- High Force (>500gf): Causes finger fatigue during repetitive tasks (e.g., scrolling through a patient menu).

- Medium-High (300gf): The "Sweet Spot" for medical panels.

Image Suggestion:

Description: A surgeon’s gloved hand pressing a "Power" button on a medical monitor, highlighting the indentation of the button.

Alt Text: Surgeon with latex gloves pressing a high-actuation force tactile switch on medical equipment.

Frequently Asked Questions

Yes. Integrated LED tact switches are popular in low-light environments (like radiology labs) to indicate device status (e.g., Green for "Ready," Red for "Alarm") directly on the button.

IP67 protects against temporary immersion (1 meter for 30 mins), which covers accidental spills or wiping. IP68 offers continuous protection under pressure, which is necessary for devices that might be fully submerged during sterilization.

If the switch is IP-rated (sealed) or covered by a membrane overlay, yes. If it is an unsealed open-frame switch, alcohol can wash away the internal lubricant and damage the contact, leading to failure.

Gold is chemically inert and does not oxidize. This is crucial for medical devices that may sit in storage for months but must work instantly when powered on. Silver contacts can tarnish over time, causing open circuits at low voltages.

Key Takeaways

- Safety First: Tactile feedback confirms actions, preventing errors in critical medical procedures.

- Sealing is Mandatory: Always specify IP67 or higher to withstand hospital-grade cleaning agents and fluids.

- Glove Compatibility: Choose higher actuation forces (250gf+) to ensure doctors can feel the click through gloves.

- Reliability: Opt for gold-plated contacts to ensure longevity and consistent performance over millions of cycles.

Conclusion

Selecting tactile switches for consumer electronics is about convenience; selecting tactile switches for medical equipment is about patient safety. By prioritizing sealed designs, appropriate actuation forces, and high-quality contact materials, engineers can build interfaces that healthcare professionals can trust in the most demanding environments.