Tact Switches for Automotive Dashboards: Designing for Safety & Feel

In the last decade, automotive interiors saw a massive shift toward "glass cockpits"—giant touchscreens replacing every knob and button. But recently, the pendulum has swung back. Drivers, safety regulators, and automakers are realizing that while touchscreens look futuristic, tact switches for automotive dashboards remain superior for safety and muscle memory.

When you are driving at 70 mph, you cannot afford to take your eyes off the road to navigate a three-layer menu just to turn on the defogger. You need a physical button. You need the distinct, unmistakable "snap" of a tactile switch that confirms, without looking, that your command was registered. This guide explores the critical role of these electromechanical components in modern vehicle interiors, focusing on safety, acoustics, and the rigorous AEC-Q200 standards.

Why "Eyes-Free" Operation Saves Lives

The primary function of a dashboard switch is not just electrical—it is cognitive. A tact switch provides two layers of feedback:

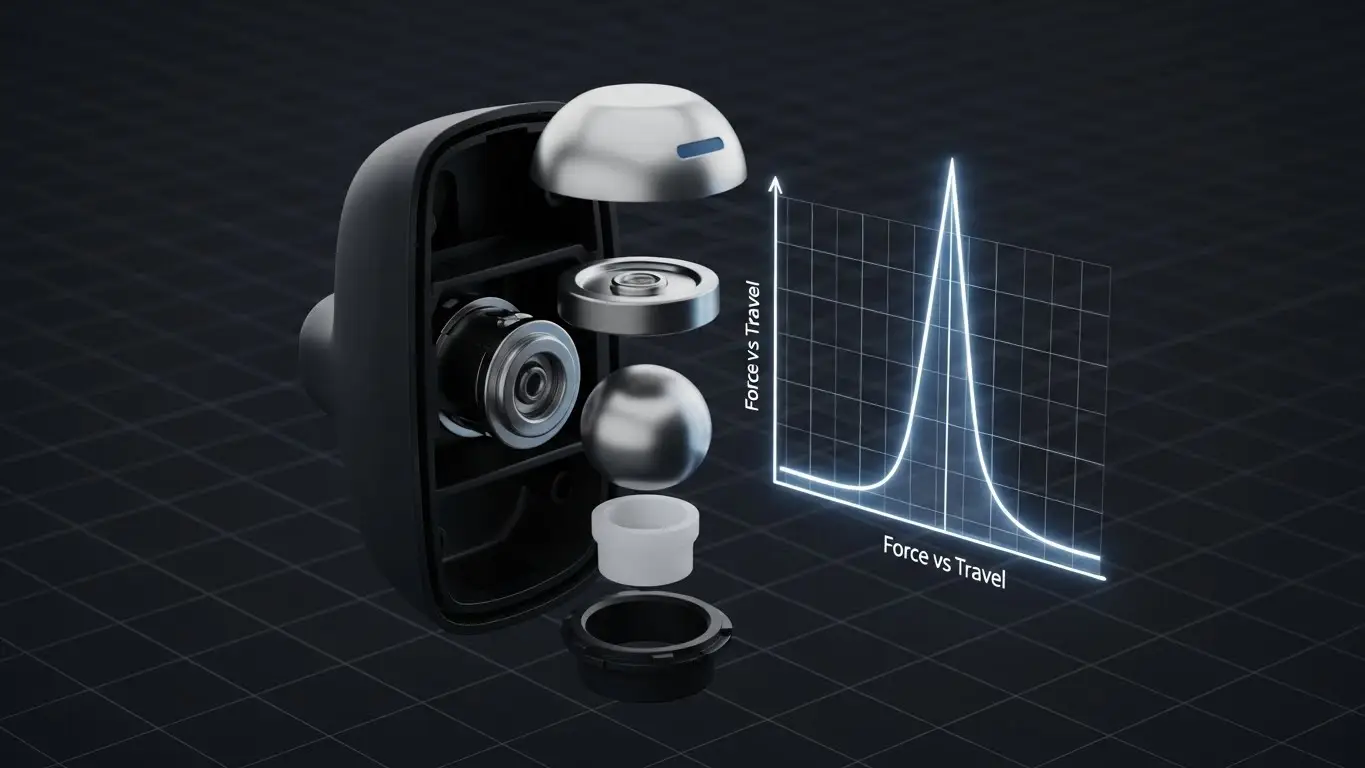

- Tactile: The collapse of the metal dome (Force-Travel curve).

- Auditory: The click sound.

This feedback loop allows for "blind operation." A driver can reach out, feel the raised volume toggle on the steering wheel, press it, feel the snap, and know the volume changed—all while watching the traffic ahead. Touchscreens, which lack this passive feedback, require visual confirmation, increasing distraction time.

The Euro NCAP Pushback

Recent updates to safety ratings (like Euro NCAP) are beginning to penalize vehicles that rely solely on touchscreens for critical functions (turn signals, wipers, hazard lights). This is driving a renaissance in high-quality physical switches.

AEC-Q200: The Non-Negotiable Standard

Unlike tact switches for gaming controllers, which sit in a climate-controlled living room, automotive switches live in hellish conditions.

- Thermal Shock: A car parked in Arizona hits 60°C (140°F), then the AC blasts it with 16°C air.

- Vibration: Constant road noise and engine rumble.

- Humidity: Winter condensation.

AEC-Q200 is the global stress test standard for passive components. An automotive tact switch must be rated to survive these extremes without "contact chatter" (unintended signaling) or mechanical failure. If you are designing for a dashboard, a standard consumer switch will likely fail within a year.

Designing the "Premium" Feel (Haptics & Acoustics)

Not all clicks are created equal. In a luxury sedan, the buttons shouldn't sound like a cheap toy.

- The "Soft" Tact: Used in luxury HVAC controls. These use rubber plungers to dampen the high-pitch "click" sound, resulting in a dull thud that feels expensive and substantial.

- The "Crisp" Tact: Used in Sport Mode buttons or paddle shifters. These use metal actuators for a sharp, loud snap that conveys precision and urgency.

Pro Tip: The "Click Ratio" (Force Drop / Peak Force) defines the sharpness. A 50% ratio feels snappy; a 30% ratio feels soft.

Key Applications in the Cockpit

1. Steering Wheel Controls

- Challenge: Limited space and high vibration.

- Solution: Ultra-low profile SMT switches with high actuation force (300gf+) to prevent accidental presses when the driver grips the wheel tightly.

2. Center Stack (HVAC & Audio)

- Challenge: Frequent use (millions of cycles).

- Solution: Long-life switches (1M+ cycles) often integrated with rotary encoders (knobs) for volume control.

3. Overhead Console (SOS & Sunroof)

- Challenge: Rarely used, but must work in an emergency.

- Solution: Gold-plated contacts to prevent oxidation during years of disuse, ensuring the SOS button works 10 years later.

Comparison: Automotive vs. Other Industries

| Feature | Automotive Dashboard | Industrial Machine | Consumer Electronics |

| Priority | Safety & Haptics | Durability & Dust Sealing | Cost & Size |

| Standard | AEC-Q200 | IP67 / NEMA | Standard |

| Life Cycle | 200k - 1M | 5k - 20k (DIP) | 100k - 500k |

| Temp Range | -40°C to +105°C | -20°C to +85°C | 0°C to +50°C |

Frequently Asked Questions

Technically yes, but it is risky. Standard switches may fail due to the temperature extremes (plastic warping) or vibration (solder joints cracking). Always specify AEC-Q200 qualified parts for critical systems.

"Sharp" switches use a metal dome that snaps suddenly, creating a loud click. "Soft" switches often use a silicone rubber stem or membrane that collapses more gradually, creating a quieter, smoother press often preferred in premium audio controls.

Yes, extensively. Night driving requires backlit buttons. Illuminated tact switches have an integrated LED or a clear plunger that sits over a PCB-mounted LED, allowing the icon (e.g., Seat Heater) to glow.

Tactile switches for medical equipment prioritize sterilization (sealing against alcohol/bleach) and extremely high reliability, but they don't face the same vibration/thermal shock challenges as automotive switches.

This is often due to "soft-touch" paint degrading over time, not the switch itself. However, if the click is gone, the silicone dome inside the switch may have torn or the metal dome has fatigued.

Key Takeaways

- Safety Critical: Physical switches allow for "eyes-free" operation, reducing driver distraction compared to touchscreens.

- AEC-Q200 is Mandatory: Only use components certified for thermal shock and vibration to ensure longevity in the vehicle environment.

- Tune the Sound: The "click" sound is part of the car's brand identity—choose rubber (soft) or metal (sharp) actuators accordingly.

- Redundancy: Even digital cockpits need physical backup buttons for Hazards, Defog, and Volume.

Conclusion

The future of tact switches for automotive dashboards is not extinction; it is evolution. As cars become computers on wheels, the need for a physical, grounding connection between the driver and the machine becomes even more vital. By selecting the right switch—one that withstands the heat, sounds premium, and clicks reliably—you aren't just designing a dashboard; you are designing a safer driving experience.