How the Slide Switch Transforms Smart Tech Design

Every smart gadget you hold today - whether a fitness band, a noise-cancelling earbud case, or a home-automation hub - relies on a Slide Switch for silent, fast, and reliable control. At Hanxia, we have spent eleven years perfecting this deceptively simple component so that device brands can focus on bold ideas instead of basic power or mode selection. Below, we share our perspective on why the Slide Switch matters, how we build it at scale, and what comes next for our partners and the industry.

Why the Slide Switch Drives Next-Gen Smart Devices

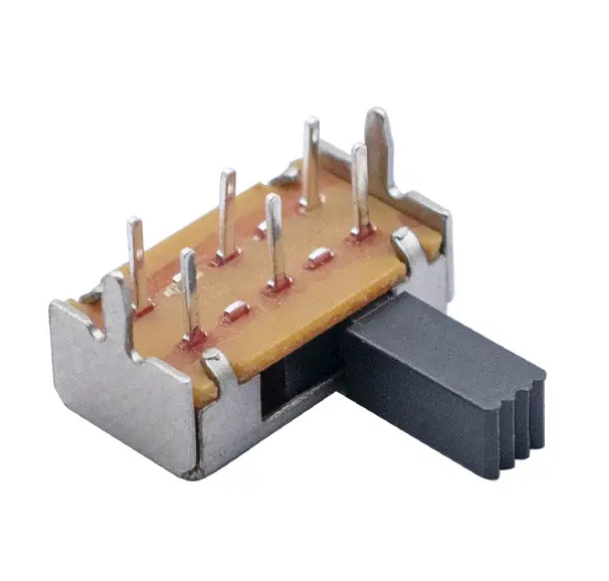

A Slide Switch looks modest, yet it solves three core design challenges: size, user delight, and durability. Users do not want to hunt for a button or wait for a capacitive sensor to wake up. They expect instant mechanical feedback - the reassuring click that tells them the device has obeyed. Engineers, on the other hand, need ultra-low resistance, minimal footprint, and long cycle life.

• Compact Form, Big Impact

The latest fitness trackers ship with battery envelopes under 50 mAh; every millimeter counts. Our most popular Slide Switch is only 2.0 mm high, allowing stacked PCB layouts that free space for larger batteries or RF shields. Despite its small frame, it endures 50,000 actuations in lab tests - more than the average lifetime toggles of a consumer gadget.

Inside the switch, a copper-alloy slider glides across silver-plated terminals. The result is ≤10 mΩ contact resistance, so the MCU sees a clean logic level without debounce headaches. Designers gain:

✅ Stable signal for firmware debouncing under 5 ms

✅ Low actuation force (180 gF typical) ideal for one-handed wearables

✅ Operational range from –40 °C to +85 °C, matching automotive specs

More important, the Slide Switch offers intuitive interaction with no learning curve. A gentle push left or right conveys power, privacy, or pairing in an instant - features touch panels still struggle to match when fingers are wet or gloved.

Hanxia's Slide Switch Manufacturing Advantage

As a specialist with 11 years in Slide Switch production, Hanxia serves brands from start-ups to listed multinationals. By 2025 we had delivered tailor-made switches to 3,625 enterprises, many of whom return year after year because we combine competitive cost with engineering depth.

• Certifications and Capacity

Our Kaiping plant runs 24 SMT lines and precision punch presses that push daily output to 2 million units. That scale lets us quote aggressive MOQs without sacrificing flexibility. Each line is ISO-certified and meets:

✅ CE, REACH, and RoHS 2.0 environmental directives

✅ Utility Patent coverage for our dust-proof slider design

✅ 100 % AOI plus functional tests at 3 A - double typical load

For a new project, our median lead time is 2-6 working days once drawings are frozen. Need a faster ramp? We reserve pilot-line slots to bridge the gap while mass tools come online. Should an unexpected issue arise, our field engineers travel on-site, troubleshoot, and fine-tune firmware debounce or housing tolerances.

• Service

Even the most reliable Slide Switch may face rough handling in the field. To protect your margins, Hanxia offers a 90-day no-reason return and exchange program on standard parts. The process is simple: submit the batch lot, describe the failure mode, and receive RMA approval within 24 hours. For custom SKUs, we analyze root causes and ship replacements or corrective kits without waiting for quarterly reviews.

Future Trends and Partner Opportunities with Hanxia

Smart gadgets are spreading from the wrist and desk to every corner of life. Analysts expect the average household to own 25 connected devices by 2028 - many battery-powered, all demanding intuitive control. The Slide Switch is evolving in three directions:

• Miniaturization Meets Multi-Function

Our R&D roadmap includes a 1.4 mm ultra-low-profile Slide Switch with dual-throw positions and an IP67 seal. That means device makers can merge on/off and mode selection into one tactile element while hitting water-resistance targets. Early samples already power AR glasses where housing depth is only 3 mm.

• Sustainable Materials and Circular Design

Regulators and consumers alike ask for greener electronics. We are shifting to recycled copper alloys and bio-based nylon sliders that lower embodied carbon by up to 30 %. A closed-loop take-back scheme lets OEMs reclaim precious metals when devices reach end-of-life.

• Co-Creation for Differentiated User Experience

Function alone is not enough; brands want a signature feel. Hanxia invites partners to co-design the actuation force curve, travel distance, and audible feedback. A Bespoke Switch Program compresses this process into four sprints: concept sketch, rapid prototype, EVT, and mass production - each phase tracked in a shared cloud dashboard.

✅ Dedicated PM guiding cross-time-zone calls

✅ 3D-printed fixtures for early enclosure tests

✅ Live data on pull force, resistance drift, and cycle wear

By combining our manufacturing muscle with your product vision, we turn the humble Slide Switch into a tactile brand asset - one users notice every day.

Ready to Power Your Next Smart Gadget?

From true-wireless earbud cases to industrial IoT sensors, the Slide Switch remains the most dependable human–machine interface. Hanxia's certified lines, rapid lead times, and unwavering after-sales support remove risk while sharpening your competitive edge. Reach out today for a free design consultation, and let's place world-class control at your customers' fingertips.