Why Roll Bar Rocker Switch Panel Ensures Long-Term Reliability

Roll Bar Rocker Switch Panel longevity is not an accident. At Hanxia, we build, measure, and verify every switch so your equipment runs longer with fewer surprises.

Why Hanxia Roll Bar Rocker Switch Panel Lasts Longer

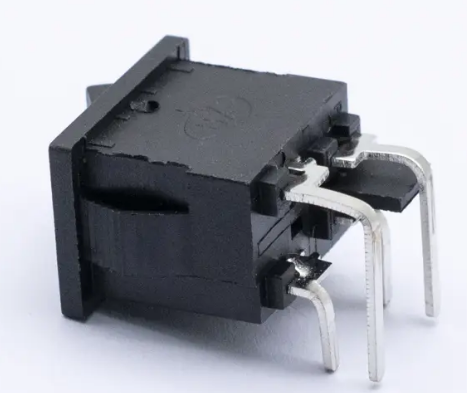

Everyone wants uptime, yet many control panels still fail early. The usual causes are familiar: inconsistent actuation force, weak insulation, poor plating, and exposure to heat or moisture. We designed the Roll Bar Rocker Switch Panel to remove those weak links. Our rocker micro switch for power control applications is compact and space-saving, so it fits tight rails, dense dashboards, and small enclosures without rework. Operators feel a low, consistent operating force, which reduces finger fatigue and contact wear. High insulation resistance and strong dielectric strength protect nearby circuits under load. A long mechanical and electrical life keeps maintenance predictable and budgets under control.

At the factory, we build for repeatability. Surfaces show no rust or plating defects, so you get a clean look and a stable contact interface. That finish does more than look good - it resists corrosion that would otherwise creep in over time. As a manufacturer, we also pay attention to assembly reality. The switch accepts multiple soldering methods without damage, which simplifies line setup and reduces rework.

Reliability You Can Measure

Numbers matter when you design for the field. Our contact resistance remains below 100 mΩ, so the switch wastes less energy and produces a clean signal. Insulation resistance stays above 100 MΩ, limiting leakage that could trigger nuisance faults. Dielectric strength of up to 1500 VAC gives you robust isolation in mixed-voltage enclosures. The Roll Bar Rocker Switch Panel operates from 0 °C to 85 °C and up to ≤ 85% RH, so behavior remains stable in typical equipment rooms, vehicles, and warehouses. The rated electrical life exceeds 10,000 cycles, which supports long deployments in everyday power-control duty.

✅ Key advantages at a glance:

- Compact, space-saving design for easy panel integration.

- Low, consistent operating force for smooth, repeatable actuation.

- High insulation resistance (≥ 100 MΩ) for safer operation.

- Dielectric strength up to 1500 VAC for reliable isolation.

- Electrical life > 10,000 cycles to reduce replacements.

- Resists temperature and humidity for stable long-term use.

These data points aren't marketing noise; they are the inputs our engineering team uses when approving each lot. By holding these targets, we reduce the small drifts that turn into field returns months later.

Built for Real Equipment, Not Just the Lab

Lab tests are a start. Real gear faces cold starts, heat soak, humid storage, and transport shock. We qualify our rocker micro switch through cold, heat, moisture, salt mist, and temperature-cycling tests. We also validate performance under mechanical shocks to protect against damage during installation and shipping. The goal is simple: the panel should feel the same on day one and year five.

A compact footprint helps every downstream step. Shorter wire runs reduce clutter and lower the chance of nicked insulation or loose terminations. Harnesses route cleanly. Panels close without forcing. These small wins add up to lower assembly time and fewer latent defects. Installers notice that the actuation “click” is repeatable across units, which builds operator confidence - an underrated benefit when teams work under time pressure.

We often hear the question: does a high insulation rocker switch panel help with noise and leakage? The practical answer is yes. When insulation resistance is high and stable, leakage paths are minimized, and control signals remain clean. That is why we align our materials and process around maintaining that value over time, not just hitting it on the day of test.

✅ Typical deployment benefits:

- Faster assembly thanks to tidy layouts and fewer cable compromises.

- Consistent “feel” across units, which reduces user error.

- Lower rework risk due to reliable plating and soldering tolerance.

- Confidence in mixed-voltage cabinets because of proven isolation.

We also recognize that service teams want predictable behavior after years of use. The weather-resistant rocker micro switch design and validated operating window help the panel shrug off routine environmental swings. You get steadier performance without redesigning the cabinet or adding costly climate control.

Where the Roll Bar Rocker Switch Panel Fits

Standardizing on one platform reduces inventory and training time. The Roll Bar Rocker Switch Panel supports broad power control applications across general electronic devices, household appliances, office equipment, audio and video devices, automotive electronic controls, industrial machinery signal control, computer peripherals, and communication equipment. This breadth lets engineers reuse a proven part across projects while keeping qualification simple.

When should you specify this panel? Choose it if you need stable switching in compact spaces, clean aesthetics that resist corrosion, and validated performance in typical temperature and humidity. The combination of > 10,000 electrical cycles, controlled actuation force, and verified insulation gives managers confidence that systems will remain online and predictable. Reduced downtime means fewer emergency calls and a healthier total cost of ownership.

✅ Quick Specification Recap

To help with design reviews, here are the essential specs your team will ask for:

- Operating range: 0 °C to 85 °C, ≤ 85% RH.

- Contact resistance: < 100 mΩ.

- Insulation resistance: > 100 MΩ.

- Dielectric strength: up to 1500 VAC.

- Electrical life: exceeds 10,000 cycles.

- Finish: no rust, no plating defects.

- Environmental tests: cold, heat, moisture, salt mist, temperature cycling; withstands mechanical shocks.

As a manufacturer, we do not treat longevity as a feature; it is a process. Material selection, plating quality, tooling control, and in-process checks all drive the same outcome: a Roll Bar Rocker Switch Panel that works the same way every time. That is what your operators feel and what your finance team sees on the maintenance line.

If you need a high insulation rocker switch panel for a new enclosure or a refresh of an existing build, our engineers can guide you on actuator profile, terminals, and mounting choices that align with your wiring practices. We can also share recommended handling steps for storage conditions within the validated 0 °C to 85 °C and ≤ 85% RH window, so the parts arrive on the line ready to perform.

Call to Action

Ready to extend the life of your control hardware with a proven, compact solution? Contact Hanxia for a spec sheet, discuss OEM customization, or book a quick design review for your Roll Bar Rocker Switch Panel program. Let's turn measured reliability into your competitive edge.