Pushbutton Switches vs. Tactile Switches: How They Differ and Which to Use

Mechanical switches are integral to nearly every electronic device, enabling user control, signaling, and automation. Among the most common types are tactile (tact) switches and pushbutton switches. Though often used interchangeably, they serve distinct purposes and differ significantly in design and operation. This guide dives into the key differences, pros and cons, applications, and selection tips to help choose the right switch for your design.

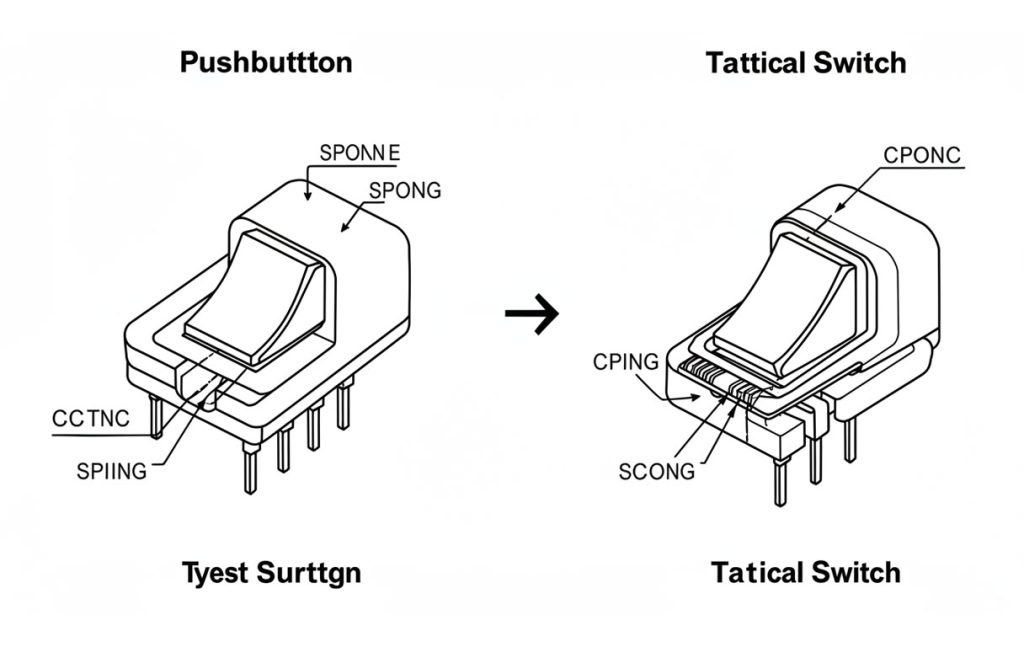

🔍 What Is a Pushbutton Switch?

A pushbutton switch (sometimes simply “pushbutton” or “push switch”) is a mechanical switch activated by pressing a button. It’s designed to make or break an electrical circuit, either momentarily or permanently until pressed again.

- Momentary type: completes the circuit only while pressed; it returns to default position when released.

- Latching type: stays in its last position after pressed—maintains on or off until manually changed again.

Pushbuttons can include visual indicators (like integrated LEDs), come in various shapes and sizes, and support current and voltage ratings suitable for power-level control.

🧩 What Is a Tactile Switch?

A tactile switch (tact switch) is a compact momentary switch designed to provide a tactile or audible click when actuated. They’re intended to affirm user input with physical feedback. These switches typically operate only while pressed and return immediately when released.

Tact switches are generally surface‑mount (SMT) or through‑hole, and often used in situations where board space is tight and feedback reliability is important.

✅ Key Differences at a Glance

| Feature | Tactile Switch | Pushbutton Switch |

|---|---|---|

| Feedback | Tactile click or bump | Varies—may be smooth or clicky |

| Operation Mode | Momentary only | Momentary or latching |

| Size & Profile | Very small, low-profile | Larger, range from mini to industrial |

| Typical Use | Low-power UI input (keyboards, remotes) | High-power control, panel operation |

| Electrical Rating | Low voltage/current | Broader (can handle higher power loads) |

| Durability | Millions of cycles in UI context | Depends on design; often heavy-duty rated |

| Sealing Options | Occasional sealed versions available | Often available with IP ratings for harsh environments |

⚙️ Functional Differences

- Tactile Switches

- Provide a crisp, predictable actuation feel.

- Ideal for feedback-sensitive UI input—like calculator buttons or remote controls.

- Typically only “make” or close while pressed.

- Pushbutton Switches

- May be momentary or latching.

- Often used to switch power, trigger devices, or integrate LEDs/pilot lights.

- Feedback depends on mechanism; may not include a tactile click unless designed to.

📌 Use‑Cases & Applications

Tactile Switch Applications:

- Consumer electronics: remote controls, calculators, game controllers, small handheld devices.

- Computer and laptop keyboards (especially compact and membrane keyboards).

- Medical devices, security systems, and industrial panels where minute inputs need reliable feedback.

Pushbutton Switch Applications:

- Control panels for appliances, HVAC, security systems, and industrial machinery.

- Power controls requiring latching functionality (e.g., push-on/push-off toggles).

- Devices offering illuminated status feedback via LED or neon indicators. en.wikipedia.org

🛠️ When to Use Which?

Choose a Tactile Switch if you need:

- Compact size and PCB-mounted input.

- Physical confirmation with every press (<‑footprint> space).

- Low-cost, high-volume UI press actions.

Choose a Pushbutton Switch if you need:

- A switch to stay in position (latching).

- Higher current or voltage switching capability.

- Industrial-grade or panel-mounted solutions.

- Integrated indicator lighting or sealed functionality.

⚖️ Pros and Cons

Tactile Switch

Pros:

- Precise tactile feedback and consistent actuation feel.

- Minimal size and footprint.

- Excellent for repeated user input.

Cons:

- Limited voltage/current capacity.

- May wear out if held down or pushed off-center.

- Audible click may not suit quiet environments.

Pushbutton Switch

Pros:

- Flexible functions: momentary or latching.

- Can carry higher voltage and current.

- Often more durable and adaptable to harsh environments (sealed, colored, backlit).

Cons:

- Bulkier form factor than tact switches.

- Tactile feedback may not be consistent unless specifically designed.

🛠️ Engineering Considerations

- Lifetime Rating: Most tact switches boast up to millions of cycles, but always validate against your expected usage.

- Mounting: SMT versions allow compact board design; through-hole variants provide mechanical strength.

- Actuation Force & Travel: Tact switches require correct alignment—off-center or excessive force can reduce life.

- Sealing and Environmental Protection: Consider IP ratings if exposed to dust or moisture. Many pushbuttons offer IP54, IP65 or higher.

- Aesthetic & UX: LED illumination or colored legends may be important for user interface design.

🧠 Final Thoughts

Although tactile and pushbutton switches often look similar and sometimes overlap in usage, understanding their core distinctions ensures better design decisions. Tactile switches excel as compact, feedback-rich UI controls on PCBs, while pushbutton switches offer flexible functionality, higher durability, and integration for panel-mounted or higher-power applications.