Product Specification

Product Description

Application Field

Why Choose Us

Product Description

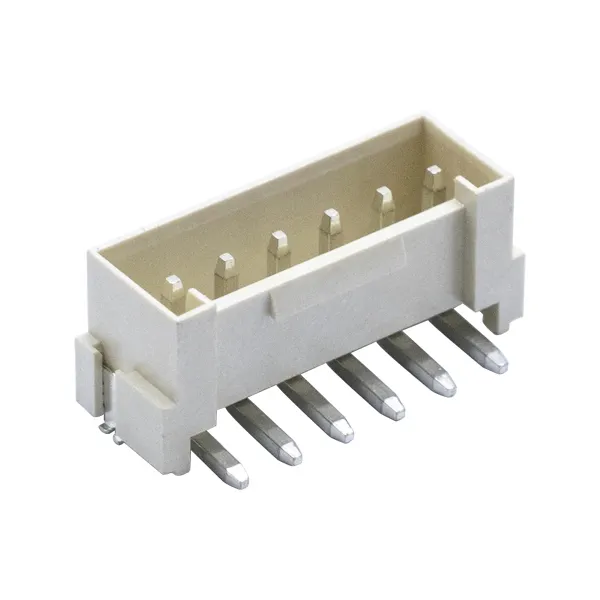

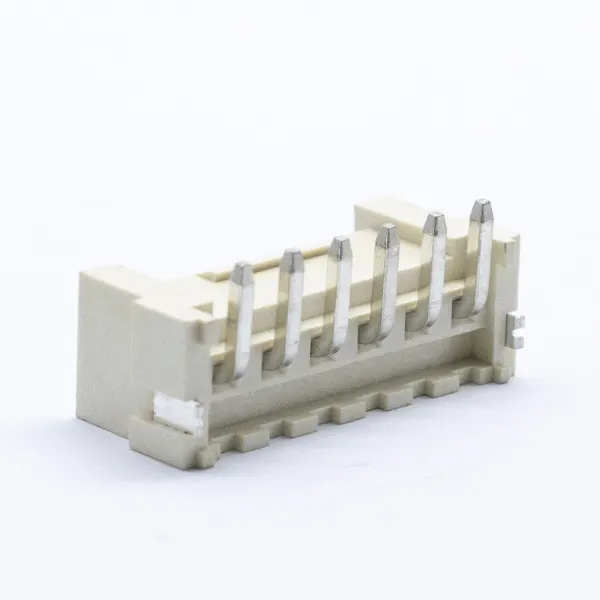

VH3.96 is a 3.96 mm pitch, medium-to-high current wire-to-board connector designed for appliances, power supplies, LED drivers, and industrial control, handling both power and signal. Available in SMT (vertical/right-angle) and THT (straight/90°) variants, it features polarization keys, friction latch/snap options, and reinforced solder/board-lock designs to improve vibration resistance and pull-out strength, while supporting automated assembly.

Key features

- Pitch: 3.96 mm; circuits: 2–12 pins (more on request)

- Mounting: SMT vertical/right-angle; THT straight/90°

- Mechanical and safety: polarized anti-mismating, optional friction latch/snap, shrouded housing walls, clear tactile mating

- Reinforcement: large pads, metal stiffener/side solder tabs, board locks for enhanced retention and vibration performance

- Mating parts: matching terminals and housings; common wire gauges AWG16–22 (terminal dependent)

- Materials and plating: housing PA66/PA9T, UL94 V-0; terminals copper alloy, nickel underplate + matte tin; selective gold on contact area optional

Electrical performance (typical; see datasheet)

- Current rating: up to ~10 A per contact (depends on wire gauge, circuit count, and temperature rise criteria)

- Voltage rating: up to 250 V AC/DC

- Contact resistance: ≤ 10 mΩ (typical)

- Insulation resistance: ≥ 1000 MΩ

- Dielectric withstand: ≥ 1500 VAC for 1 minute

Environmental and reliability

- Operating temperature: −25 to +105 °C

- Lead-free reflow compatible; halogen-free options available

Assembly and soldering

- SMT: tape-and-reel supply; optional pick cap; recommended land pattern and stencil apertures provided; reflow per J-STD-020

- THT: supports wave/selective solder; use fixtures and post-solder reinforcement as applicable

Compliance and documentation

- RoHS and REACH compliant

- 2D drawings, PCB footprints and libraries, 3D STEP, and soldering/handling guides available

Packaging

- Standard tape-and-reel (SMT); tray/box optional (THT/large bodies)

Typical applications

- White goods control boards, AC/DC power supplies, LED drivers

- Industrial control, HVAC, relay/IO modules

- Battery packs and charging/energy storage modules

Selection and ordering example

- Part number format: Series – Pitch – Mount – Orientation – Positions – Plating

- Example: VH – 3.96 – SMT – RA – 06P – Sn

- Final part numbers, dimensions, pad layouts, and performance limits are per the official datasheet; wire harness customization available (cut/strip/crimp, length, overmold, testing, labeling, etc.).