Product Specification

| Series | Tact Switch |

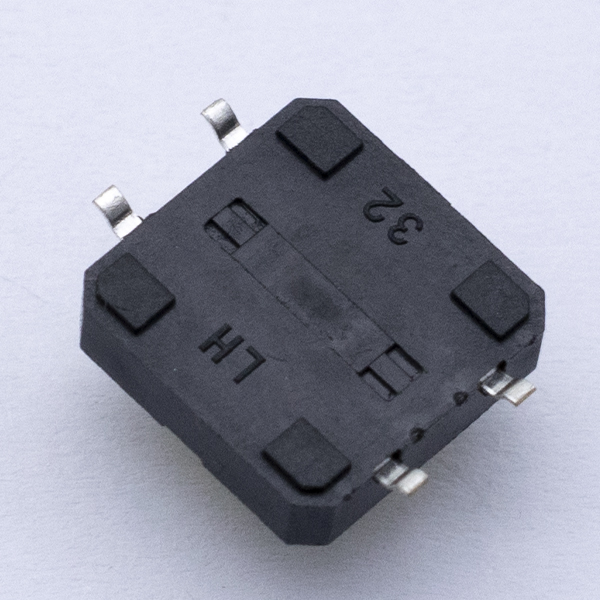

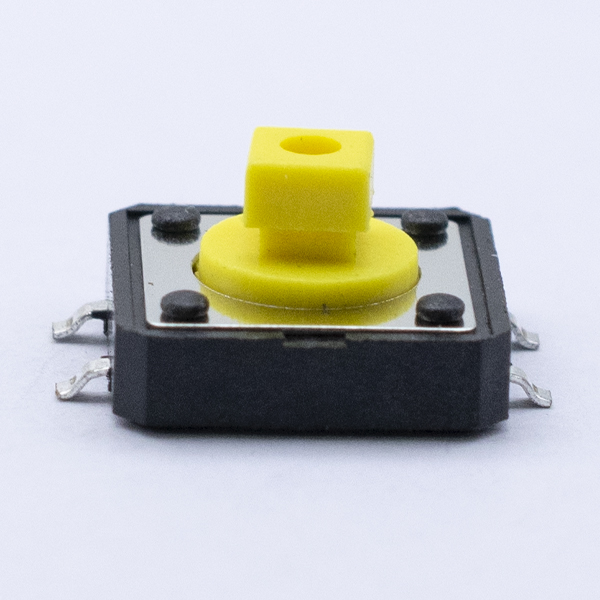

| Model | HX TS1273TP |

| 1. Operating Temperature: | -25-+70°C |

| 2. Rated Load: | DC 12V 50mA |

| 3. Contact Resistance: | ≤100mΩ |

| 4. Insulation Resistance: | ≥100mΩ |

| 5. Withstand Voltage: | AC 250V (50Hz)/min |

| 6. Operating Force: | 250 ± 50g |

| 7. Service Life: | 100,000 cycles |

| 8. For tolerances not specified, refer to the table below. | |

Product Description

The SMT tact switch is a high-performance, compact switch designed for industrial control applications. Engineered with precision, it offers reliable performance in demanding environments, ensuring long-term durability and functionality.

This switch features Surface Mount Technology (SMT), making it easy to integrate into automated production lines, saving valuable space in control panels and machinery interfaces. Its small size does not compromise its strength, as it is built to withstand harsh conditions like vibration, temperature variations, dust, and moisture.

Materials:

- Insert: H62Y brass, T=0.30, Ag

- Base: PPA (black)

- Reed: Stainless steel, Ag

- Cover: Cold-rolled steel strip, Cu/Sn

- Button: PPA (yellow)

Application Field

SMT tact switches are widely used in various industrial control systems due to their compact design, reliability, and precision. Some of the primary application fields for SMT tact switches in industrial control include:

- Control Panels: SMT tact switches are commonly used in control panels to manage machinery and automated systems. They allow operators to control various functions with precision and provide tactile feedback for accurate decision-making.

- Automation Systems: In industrial automation, SMT tact switches are used for controlling automated machinery and robotics. They play a critical role in ensuring smooth operation by offering reliable and responsive control inputs.

- Machine Interfaces: SMT tact switches are integrated into machine interfaces for industrial equipment. These switches help operators interact with machines, adjusting settings and monitoring system status.

- Process Control: SMT tact switches are essential in process control systems used in manufacturing, chemical processing, and assembly lines. They help regulate processes by providing precise control over system inputs and outputs.

- Embedded Systems: In embedded control systems, SMT tact switches are used to enable user interaction with devices. They allow for easy and precise control, especially in systems with limited space for traditional switches.

- Test Equipment: SMT tact switches are frequently used in industrial test and measurement equipment, where accuracy and reliability are essential. They provide dependable input for controlling testing processes and adjusting settings during measurements.

- Power Distribution Systems: SMT tact switches are utilized in power distribution control panels and systems. They offer easy switching and precise control over the distribution of power across large industrial setups, helping to maintain operational efficiency.

- Data Acquisition Systems: For data acquisition and control applications, SMT tact switches offer reliable input methods for monitoring and collecting data from various sensors or equipment in industrial environments.

These SMT tact switches for industrial control ensure efficient operation in critical systems, providing robust performance and precise control in harsh environments.

Why Choose Us

Choosing Hanxia means choosing quality, reliability, and excellent service. Here’s why we are the trusted choice for electronic component manufacturing:

1. Extensive Industry Experience

With over a decade of expertise since our establishment, Hanxia has built a strong reputation in the electronic components industry. We serve a global customer base, including stable partners in the U.S., Germany, South Korea, Japan, Hong Kong, and Taiwan.

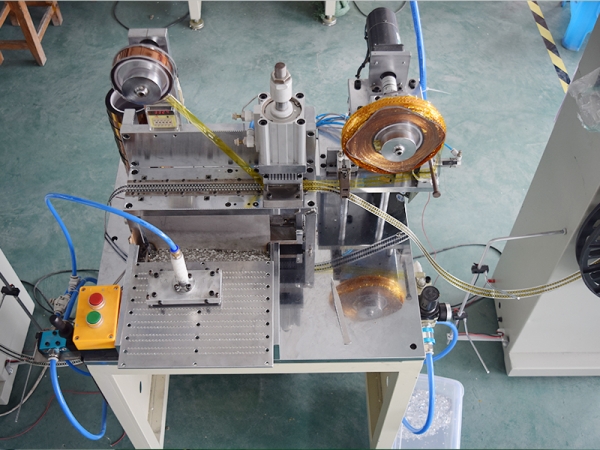

2. Advanced Automated Production

- 38 fully automated production lines with a daily output exceeding 2 million pieces, ensuring fast and reliable delivery.

- Technical collaboration with Korean experts, utilizing fully automatic assembly to minimize errors and improve efficiency.

3. Stringent Quality Control

- Multiple quality checkpoints, including raw material inspection, online sampling, and finished product checks.

- 100% factory inspection guarantees every product meets the highest industry standards.

4. Fast & Risk-Free Delivery

- Zero-risk delivery with on-time shipping worldwide.

- 365-day return policy for quality issues, ensuring customer satisfaction.

At Hanxia, we prioritize innovation, quality, and customer satisfaction, making us a trusted partner in the global electronics industry.

|

|

|

|

|

|

Hanxia, established in 2008, specializes in the R&D and production of switches and sockets. Its production base is in Wenzhou, Zhejiang, with 110+ employees and a 4,300 m² facility, and a sales branch in Bao'an, Shenzhen, for customer service. Hanxia serves 3,500+ customers globally, with stable partners in the U.S., Germany, South Korea, Japan, Hong Kong, and Taiwan. It has a strong sales presence in China's Pearl River Delta and collaborates with listed companies like Alibaba Tmall Magic Box, PISEN Group, and Panteng Technology. The company offers fast, reliable global delivery, a 365-day return policy for quality issues, and professional engineering support, earning widespread customer trust.