Space-Saving PCB Layouts Using Plastic Mini Slide Switch Options

Plastic Mini Slide Switch solutions help engineers design compact, efficient, and reliable products without sacrificing usability or service life. At Hanxia, a leading manufacturer of switches in China, we help teams that are fighting for every millimeter on the PCB. Products keep getting thinner; user expectations keep going up. Below, we share practical guidance, failure patterns to avoid, and how our Micro Slide Switch With Adjusting Functions supports space-constrained layouts while preserving accuracy and low power.

Why Smarter Switching Unlocks Smaller Boards

Shrinking a board is more than pushing parts closer together. It's a balancing act between enclosure geometry, assembly flow, heat, and signal integrity. The humble Plastic Mini Slide Switch influences each of these areas. Its location defines the wall thickness of the housing, the shape of the user interface, and even how your product sounds and feels when operated.

Teams often choose a tiny footprint and hope size alone solves the problem. It rarely does. A compact device still needs crisp actuation, stable contact resistance, and low current draw under real conditions - heat, vibration, dust, and repeated use. Cut corners here, and you invite intermittent operation, "no-click" complaints, and rework on the line. Hanxia focuses on tight mechanical tolerances and tuned operating force so a small switch still feels deliberate and lasts.

✅ The Hidden Constraints Designers Face:

• Limited edge real estate and tight bezel clearances

• Interference between actuator travel and nearby parts

• Assembly variance that dulls tactile feedback

• Contact resistance drift due to wear or contamination

• Strict battery budgets in handheld devices

These constraints are normal. The fix is thoughtful placement, reliable mechanics, and early validation - before enclosure tooling locks in your assumptions.

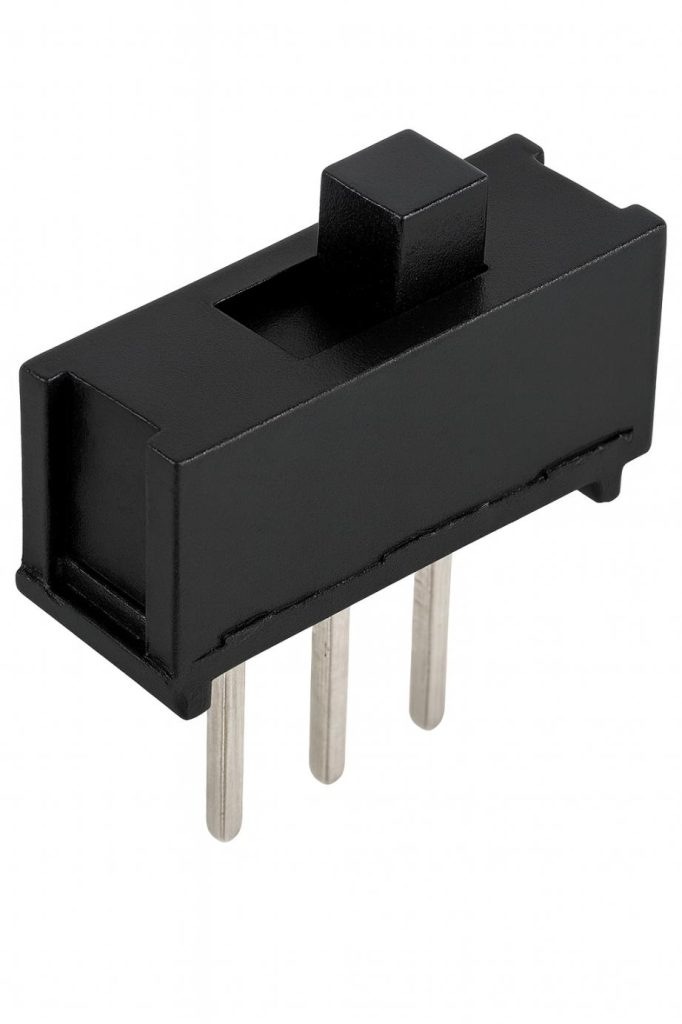

Inside Hanxia's Micro Slide Switch With Adjusting Functions

Our Micro Slide Switch With Adjusting Functions serves both simple on/off duties and fine adjustments such as volume, speed, and mode selection. The sliding action is smooth and repeatable, helping users land precisely on the setting they want - no overshoot, no wobble. The package is compact, so it fits cleanly at a board edge or under a slim fascia where finger travel is short and predictable.

What it delivers in real products:

• Long-lasting reliability - Contact geometry and materials resist wear, limiting drift over life.

• Precise actuation - A consistent force curve supports accurate control, even behind thin plastic or metal.

• Compact design - Saves PCB area and reduces enclosure depth.

• Low power consumption - Supports battery-first designs and reduces heat.

• Broad compatibility - Works across consumer, medical, industrial, automotive, and communication devices.

✅ Key electrical and mechanical data:

• Rated value: DC 12 V, 50 mA

• Contact resistance: ≤ 100 mΩ

• Insulation resistance: > 100 MΩ

• Operating force: 250 ± 50 g

These values align with low-current logic and user-facing controls. The operating force is tuned for a confident "click" without excess stiffness, which keeps the interaction consistent even after enclosure assembly tolerances stack up.

✅ Where It Fits Best:

• Consumer Electronics - Remotes, audio gear, and home appliances that need clear mode changes.

• Medical Devices - Portable instruments where precise adjustment and low power are essential.

• Industrial Equipment - Fine control and safe enable/disable in compact panels.

• Toys & Gadgets - Small controls that survive frequent, sometimes rough, use.

• Automotive - Lighting, entertainment, and auxiliary systems that benefit from tactile certainty.

• Communication Devices - Radios and intercoms requiring stable contacts and reliable feel.

Practical Layout Tactics For Saving Space

The right Plastic Mini Slide Switch can unlock millimeters - if you design around it early. Below are field-tested tactics we recommend to OEM teams.

1) Start With Human Access, Then Route

Reserve the actuator window on day one. Map finger travel, wall thickness, and cap height before finalizing routing. This avoids late changes that push parts outward and bloat the enclosure.

2) Align To The Edge To Reclaim Depth

Mount the switch parallel to the board edge to reduce internal overhang. If the stackup is tight, consider reversed or low-profile orientations. Shorter actuator paths improve feel and reduce assembly variability.

3) Budget Your Stackup Tolerances

Small parts magnify small errors. Account for PCB thickness variance, boss height, and enclosure flex. A thin shim - 0.2 to 0.3 mm - can remove rattle, restore a clean click, and protect long-term feel.

4) Keep Heat And Noise Away From Contacts

Route high-current or noisy traces elsewhere. Avoid crowding the switch with inductors or heat sources. A cooler, quieter neighborhood keeps contact resistance stable across the product's life.

5) Validate Force In The Final Housing

Measure actuation after bezels, gaskets, and coatings are installed. Interface friction changes perceived force. Aim to meet the 250 ± 50 g target in the finished product, not just on the bare PCB.

6) Design For Assembly And Field Service

Use clear silkscreen marks and fiducials to help pick-and-place. If rework is possible, allow access without tearing down the full front panel. Seconds saved per unit become real money at scale.

7) Prove Reliability With A Focused Checklist

• Cycle the mechanism under realistic load and temperature.

• Run vibration and drop tests with the actual enclosure in place.

• Measure contact resistance drift before and after environmental stress.

• Inspect for dust ingress and debris along the slider path.

✅ What Goes Wrong When Corners Are Cut

• Intermittent operation from debris accumulation or contact bounce.

• Flat, mushy feel due to misalignment between cap and actuator.

• Audible rattle from insufficient support under the switch.

• Premature wear when heat and vibration exceed the design envelope.

These failures are avoidable. Most stem from late placement changes, unverified tolerances, or choosing a switch on size alone. Pairing a robust Plastic Mini Slide Switch with early ergonomic planning solves the bulk of them.

Bring Your Next PCB Down To Size - Without Compromise

If your team is under pressure to hit a slimmer enclosure, faster assembly, and better battery life, Hanxia can help. Our Plastic Mini Slide Switch solutions and Micro Slide Switch With Adjusting Functions are engineered for tight spaces, repeatable feedback, and stable electrical performance. Contact Hanxia's engineering team for samples, drawings, and quick DFM advice. We'll review placement, stackup, and access windows so your next board is smaller, cleaner, and built to last.