Enhance Product Safety Using a Panel Mount Slide Switch

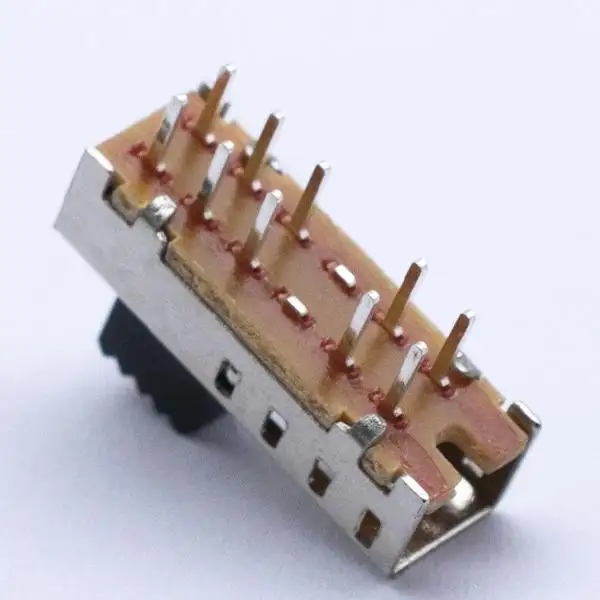

A Panel Mount Slide Switch looks small, but it can change how safe a product feels. It is a front-panel control that moves in a straight line to select a clear state. One slide. One decision. No guesswork. It mounts securely on the enclosure and connects to low-power control lines. The action is crisp, so operators feel each step even with gloves. In busy plants, that clarity matters. Fewer errors. Faster checks. But the real value hides in how it handles noise, vibration, and daily wear. Want to know why this tiny switch protects big systems? Keep reading.

Safety You Can Feel, See, And Trust

People notice when a control feels right. That starts with the tactile profile. Our Hanxia Panel Mount Slide Switch uses a precise sliding mechanism with a deliberate operating force of 250 ± 50 g. It resists casual bumps yet glides smoothly when an operator intends to switch. The travel has clear detents, so technicians feel position changes even through gloves and in noisy areas where alarms and motors drown out ambient cues.

Electrical integrity backs up that mechanical feel. Contact resistance ≤ 100 mΩ stabilizes low-level signals headed to PLC inputs, reducing chatter and false trips. Insulation resistance > 100 MΩ helps keep mixed-voltage cabinets quiet, protecting adjacent circuits from leakage paths. The device is rated at DC 12 V, 50 mA, making it a natural fit for enable lines, logic control, indicators, and other low-power switching points found across modern automation cells.

Safety also depends on visibility and placement. Because this is a panel-mounted device, it lives on the front door where decisions happen - start/stop, mode select, or maintenance override. When paired with simple nameplates and color bands, the Panel Mount Slide Switch gives unmistakable feedback: operators can confirm state at a glance and auditors get the clear labeling they expect during walk-throughs and lockout/tagout checks.

- Why Engineers Pick Hanxia?

• Compact body that conserves panel space in crowded enclosures

• Low power draw that minimizes heat in dense control cabinets

• Durable materials for repetitive use in dusty, high-vibration zones

• Consistent actuation so every workstation feels the same across shifts

Where The Panel Mount Slide Switch Makes The Biggest Difference

If you build or maintain industrial equipment, you've seen how small interface choices ripple through uptime and safety scores. Here are the applications where customers tell us the Hanxia Panel Mount Slide Switch pays for itself:

- Industrial Control Systems

On conveyors, robotic cells, and process skids, operators need quick, honest control over enable lines and operating modes. A positive detent reduces mis-operations when a line starts, pauses, or ejects a part for inspection.

- Machinery And Equipment Controls

Automated machinery often requires frequent transitions - setup, run, purge, service. A slide action suits these workflows because it demands intent yet stays simple to clean and inspect. Mode selection becomes predictable, which means fewer training gaps and fewer "why did it do that?" moments.

- Factory Automation

In integrated systems, the Panel Mount Slide Switch ties neatly into PLC logic. Low contact resistance supports reliable sensing, and insulation headroom helps on cabinets that pack IO cards, VFDs, and power supplies in close quarters.

- Electrical Equipment

HVAC units, pumps, and motors often need local state changes while maintenance teams are on site. The switch's feel communicates status immediately - no second guesses, no hunting through HMI screens while a fan is still spinning.

- Power Distribution Panels

For auxiliary circuits and feeder enables, a front-panel slide offers clear intent without the bulk of lever hardware. It also makes documentation easier: label it once and train once, then replicate across cabinets.

✅ Practical Integration Tips From The Field

- Use the Panel Mount Slide Switch on low-power control paths and interlocks rather than high-inrush loads.

- Place it in the operator's natural reach path; label both ends of travel to match standard work.

- Pair it with status LEDs and SCADA tags so state is visible locally and in the control room.

- Standardize the actuation force across stations so muscle memory reduces mistakes.

Building Safer Panels, Faster - The Hanxia Approach

Design time is precious, and so is panel real estate. Our compact footprint lets you keep human-machine controls within the ergonomic "golden zone," not scattered wherever space remains. Shorter wire runs reduce crosstalk and heat; lower power use eases thermal budgets in tightly packed enclosures. For maintenance teams, easy access and consistent feel translate into fewer errors during shift changes and quicker recoveries after faults.

What about long-term performance? Safety isn't just "day one." It's cycle after cycle, week after week. We build for that. Tight tolerance on contacts maintains ≤ 100 mΩ performance as the device ages; insulation stays high to protect adjacent circuits; the sliding geometry keeps its crisp detent so operators don't have to "guess the click" a year later. When the interface remains stable, training sticks, audits go smoother, and root-cause investigations get shorter because inputs behave exactly as expected.

From an ROI perspective, small decisions compound. A clearly labeled, predictable Panel Mount Slide Switch lowers nuisance trips, reduces accidental mode changes, and prevents the kind of ambiguous input that sends technicians hunting through PLC code. The result is less downtime and more focus on throughput.

✅ Quick Spec Snapshot (For Fast Reviews)

- Rated Value: DC 12 V, 50 mA

- Contact Resistance: ≤ 100 mΩ

- Insulation Resistance: > 100 MΩ

- Operating Force: 250 ± 50 g

- Form Factor: Panel-mounted slide for control doors and HMIs

✅ Common Pain Points We Address

- Ambiguous controls that create audit findings

- Inconsistent switch feel across stations, hurting training and muscle memory

- Heat buildup from crowded layouts and high current hardware

- False triggers from noisy signals in mixed-voltage cabinets

By targeting these everyday issues, Hanxia helps teams turn a modest component into a meaningful safety upgrade.

Call To Action: Build Safer, Clearer Interfaces With Hanxia

If you're planning a new control panel or retrofitting legacy gear, let's talk. Our engineering team can help you integrate the Hanxia Panel Mount Slide Switch with the right placement, labeling, and diagnostics so your operators make confident moves - and your equipment follows without hesitation. Reach out for drawings, compliance notes, and evaluation units. Let's design panels that protect people and keep production moving.