Why a Multi-Directional Tact Switch Matters in Devices

Multi-Directional Tact Switch technology gives designers precise control in a compact footprint with dependable tactile feedback – exactly what modern, safety-critical devices require. At Hanxia, we build and supply switches that help engineering teams simplify layouts, strengthen usability, and shorten time-to-market without trading away reliability.

The Case for a Multi-Directional Tact Switch

Across medical, lab, and industrial projects, the operator interface must be small, intuitive, and power-efficient. A single Multi-Directional Tact Switch can replace several discrete buttons, trimming PCB area and simplifying the enclosure. That consolidation reduces assembly steps and lowers the chance of wiring or labeling errors. The definitive “click” confirms each action even when screens or audio buzzers are not appropriate, which is common in quiet wards or low-light labs.

From our work with device makers, a few pain points surface again and again: limited board space, strict power budgets, and the need for a consistent, repeatable feel over the full product life. A well-specified Multi-Directional Tact Switch addresses each issue. It delivers precise actuation, supports lean power design, and improves accessibility. Users can navigate menus or engage modes with minimal motion – important for gloved operation and time-sensitive tasks.

✅ Design Pain Points We Solve

- Tight PCB space that forces UI compromises

- Inconsistent feedback from low-grade switches

- Power limits that constrain indicator options

- Tedious assembly created by multi-button arrays

✅ How It Elevates the User Experience

Directional input plus a crisp tactile response makes the interface predictable and fast to learn. Fewer controls mean fewer errors. The short, clean travel tells the operator the command registered, which reduces double presses and improves throughput. Maintenance teams also benefit: when the switch delivers uniform feel over time, calibration checks and service calls become more straightforward.

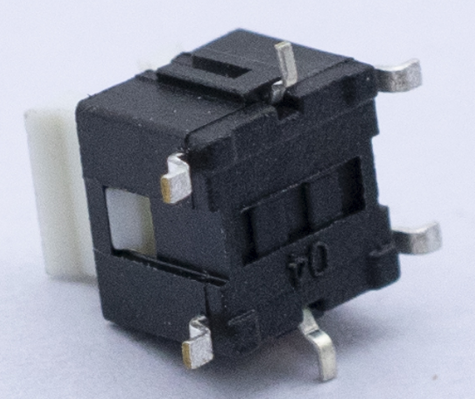

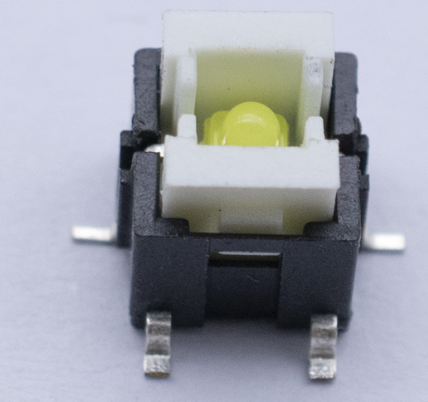

Hanxia‘s SMD Multi-Directional Tact Switch with LED

For medical and diagnostic equipment, our Hanxia SMD 6x6x7.2 Tact Switch with LED combines reliable tactile feedback with a clear visual cue – an ideal pairing for critical environments. We engineered this component to help teams build safer, clearer interfaces without growing the footprint. If you are sourcing an LED tact switch for medical devices or an SMD 6x6x7.2 tact switch, this model aligns with frequent healthcare requirements while keeping integration simple.

✅ Key Advantages

- Long-lasting reliability for stable performance

- Precise actuation that supports accurate operation

- Compact design that saves valuable space

- Low power consumption to enhance efficiency

- Compatibility across a wide range of uses

✅ Core Specifications

- Item Name: Touch switch TS6672TP white light 097

- Operating Temperature: -25 to 70℃; Relative Humidity: ≤80%RH

- Rating: 50mA 12V DC

- Contact Resistance: ≤100mΩ; Insulation Resistance: ≥100mΩ

- Operating Force: 250gf±50gf; Contact Journey: 0.25±0.1mm

- Dielectric Strength: 250V 50Hz 1min

- Lifetime: 100,000 cycles

These figures reflect a balanced design. Short travel supports quick, confident input. Actuation force is firm enough to avoid accidental presses yet comfortable for repeated use, including gloved operation. The integrated LED offers immediate visual confirmation, which improves workflows on busy floors and supports safe operation in dim environments.

✅ Applications in Healthcare Environments

Our Multi-Directional Tact Switch fits patient monitoring systems, medical diagnostic equipment, infusion pumps, hospital control panels, and laboratory instruments. The 6x6x7.2 mm SMD format streamlines pick-and-place assembly and helps reclaim panel space for sensing or communications modules. Because the LED is integrated, teams can simplify the front panel while maintaining clear, repeatable user actions.

Practical Selection Guidance for Engineers

When selecting a Multi-Directional Tact Switch for healthcare or other precision devices, evaluate fit, feel, and safety first. Start with the operating environment. A range of -25 to 70℃ and ≤80%RH covers common clinical and lab conditions, which reduces the risk of drift in feel or performance during seasonal changes. Next, match electrical requirements. The 50mA 12V DC rating maps well to low-power control circuits and helps preserve overall system efficiency. If your design depends on immediate confirmation, prefer an integrated-LED model; it avoids separate light pipes or indicators and cuts wiring complexity.

Feel matters. The 250gf±50gf force profile produces a deliberate, positive press. Coupled with 0.25±0.1mm travel, the operator receives a crisp signal that the input registered, even through nitrile or latex gloves. Reliability is equally important in regulated markets. With a 100,000-cycle lifetime, the switch supports routine use in critical applications. The 250V 50Hz 1min dielectric strength adds margin within a properly designed system, aiding compliance efforts.

Board layout is often the hidden constraint. The compact SMD 6x6x7.2 footprint frees area for sensors, batteries, or wireless modules. That space savings can shrink the enclosure or enable new features without complicating the UI. It is the reason many teams replace multi-button clusters with one Multi-Directional Tact Switch: fewer parts to source, less firmware mapping, and faster onboarding for technicians.

From a manufacturing perspective, consistency across builds is essential. We recommend locking the land pattern early and validating reflow parameters to keep actuation force uniform across production lots. Plan LED behavior during the UX phase rather than post-layout. Define color and blink patterns that align with clinical workflows – steady for “ready,” slow pulse for “standby,” for example – so teams can read the device state at a glance without consulting a manual.

To help you move quickly, here is a concise checklist we share with customers during design reviews:

- Confirm ambient temperature and humidity against -25 to 70℃, ≤80%RH

- Map UI actions to directional inputs to eliminate extra buttons

- Validate feel with gloves and under low-light conditions

- Specify LED states early to avoid late-stage firmware churn

Taken together, these steps reduce rework and improve first-pass yield. They also make certification smoother, because the interface behavior is clean, consistent, and easy to document.

Ready to prototype with Hanxia? Tell us about your project and request samples of Touch switch TS6672TP white light 097. Our engineers can review your schematic and panel layout, then recommend the best Multi-Directional Tact Switch configuration for your build. Contact Hanxia today to discuss pricing, availability, and quick-turn support – and move from concept to reliable production with confidence.