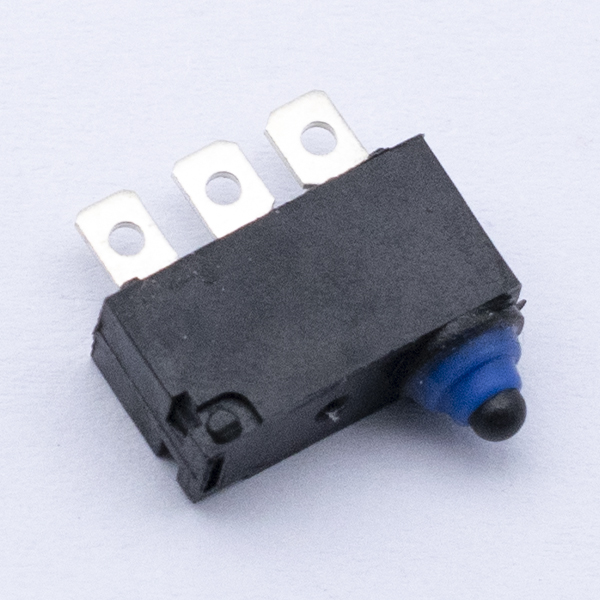

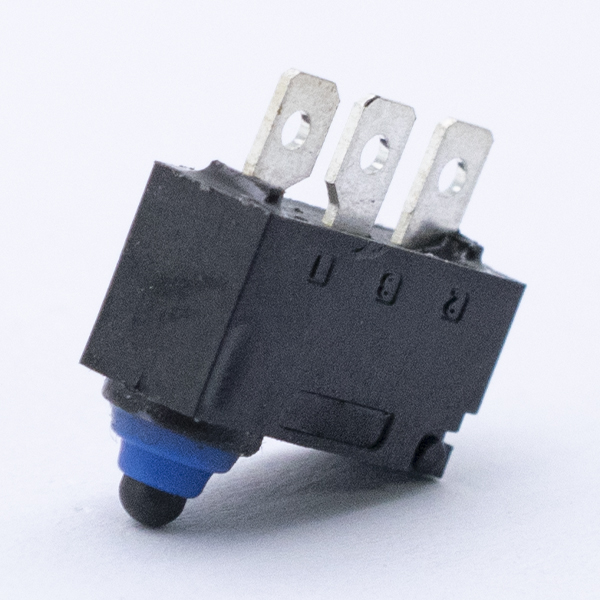

Micro Mechanical Switch vs Traditional Switch: Key Differences

Micro Mechanical Switch performance shapes how devices feel, respond, and survive in the field. From Hanxia's manufacturing floor to your assembly line, our goal is simple: deliver a reliable switch that drops into compact designs, tolerates tough conditions, and keeps your engineering team focused on the product - not the parts.

Why Micro Mechanical Switches Are Different

Traditional switches were born in an era of roomy enclosures and mild environments. They still work, but the trade-offs show up as devices shrink and duty cycles rise. A Micro Mechanical Switch is built for today's constraints: small footprint, consistent actuation, and low power. Those attributes translate into cleaner signals, tighter safety margins, and fewer field issues over the life of the product.

Space and Actuation Precision

Packaging rules many design decisions. A Micro Mechanical Switch occupies minimal real estate, freeing space for seals, cable routing, and sensors. Short travel and a defined actuation point reduce bounce and timing drift, so triggers are clean and repeatable. That matters in door sensors, window controls, and compact HMI modules where a late or noisy edge can confuse the controller. Legacy, traditional switch formats typically need more room and show larger variation as components wear.

Protection and Longevity

Environment is the silent failure mode. Dust, moisture, and salt fog attack unsealed hardware, causing intermittent contacts and rising resistance. Hanxia engineers against these risks with IP67 or IP68 sealing. Our Micro Mechanical Switch keeps its feel and resistance values even when exposed to water or fine particulates. Traditional non-sealed parts often require earlier replacement and create avoidable maintenance windows - costs that rarely appear on the BOM but show up in service reports.

What the Specs Mean in the Real World

Numbers only help if they map to outcomes. Below is how Hanxia's core specifications connect to the pain points we've seen across automotive, marine, outdoor, and industrial programs.

- Long-lasting reliability - Fewer intermittent faults and fewer returns.

- Precise actuation - Predictable signals support safer control logic.

- Compact design - More room for seals, batteries, or antennas.

- Low power consumption - Better battery life and less thermal stress.

- Broad compatibility - Smooth integration with common control boards.

✅ Electrical Fundamentals

- Rated value: DC 12V, 50 mA - Fits low-voltage systems and logic inputs without oversizing traces or drivers.

- Contact resistance: ≤ 100 mΩ - Helps maintain crisp voltage levels and minimizes heating at the contact.

- Insulation resistance: > 100 MΩ - Reduces leakage paths that can complicate diagnostics in humid conditions.

- Operating force: 250 ± 50 g - A balanced feel that's firm enough to avoid false triggers yet light enough for small actuators.

- Waterproof rating: IP67 / IP68 - Designed to withstand water and dust ingress in real-world deployments.

These parameters address the issues that frustrate builders most: creeping corrosion, unstable contacts that ghost-trigger inputs, and housings that grow just to accommodate oversized hardware. With the IP67 micro switch for automotive electronics as a flagship capability, Hanxia simplifies validation without rewriting your enclosure or gasket strategy.

✅ Mechanical Feel and Integration

Tactility is not just comfort - it is signal integrity. The controlled 250 ± 50 g force profile creates a repeatable actuation point that your firmware can trust. Pair that with the compact footprint and you gain layout flexibility: shorter levers, cleaner actuator geometry, and less friction in the stack-up. Because our Micro Mechanical Switch is designed for low power draw, thermal modeling is easier and battery calculations are less pessimistic. In volume production, that means fewer last-minute board reworks and clearer margins during compliance testing.

Applications and Buying Guidance

A Micro Mechanical Switch excels when space is limited, environments are harsh, or signal fidelity is critical. A traditional switch still has a place in clean, roomy panels where cost is the only driver. The right choice balances environment, footprint, and lifetime cost - not just unit price.

Automotive and Marine

Vehicles live with splash, humidity, and vibration. Hanxia supplies car door sensors, window controls, and safety-related interfaces where a missed trigger is unacceptable. In marine equipment - boats, ships, and offshore platforms - salt spray accelerates corrosion and exposes weak seals quickly. Our waterproof micro switch for marine equipment maintains stable performance where non-sealed traditional parts lose consistency.

Outdoor and Industrial Equipment

Outdoor lighting, garden tools, and weatherproof gadgets need compact, sealed switches that do not consume maintenance hours. In factories, processing plants, and agriculture, dust and washdowns are routine. With IP67/IP68 sealing and tight contact specs, Hanxia's Micro Mechanical Switch helps reduce nuisance trips, extends service intervals, and supports predictive maintenance without redesign. The result is more productive uptime and a calmer support queue.

Quick Decision Guide

✅ Choose Micro Mechanical when:

- You must save space without giving up tactile accuracy.

- The device faces water, dust, or salt spray frequently.

- Power budgets are tight and heat must be controlled.

- Consistent actuation is tied to safety or user experience.

✅ A Traditional switch can suffice when:

- The environment is clean, indoor, and low duty cycle.

- Housing volume is generous and occasional rework is acceptable.

How Hanxia Reduces Risk

From a manufacturer's perspective, repeatability beats hero parts. We design for consistent operating force, stable contact resistance, and robust sealing that holds up across production runs. That consistency shortens your qualification cycle and limits surprises during field use. Our teams work closely with OEM engineers on actuation geometry, lever design, and enclosure sealing so the final product feels right and lasts.

Call to Action

Evaluating a Micro Mechanical Switch for your next build? Contact Hanxia for samples, drawings, and a quick DFM discussion. We'll help you match operating force, electrical rating (DC12V 50mA), and sealing (IP67/IP68) to your environment and assembly needs - so your product ships on schedule and performs for the long haul.