Comparing LED Push Button Tact Switch vs Traditional Mechanical Switches

An LED Push Button Tact Switch is a compact, low-power momentary switch with built-in illumination, delivering crisp tactile feedback and precise actuation for control panels, smart devices, and modern LED lighting interfaces. But LED Push Button Tact Switch or traditional mechanical switch - which one truly fits modern lighting control? At first glance, both look similar. Both click, both turn things on and off. But in tight spaces, under heat, and over thousands of presses, the story changes. Tact switches promise clean signals and a crisp feel. Mechanical parts offer familiar feedback and rugged charm. Power budgets, panel density, and user touch all tip the scales. In our tests, small details made big differences. Want to know which wins in real projects - and why? Keep reading. The result may surprise your next design.

What Changes In Daily Use

For basic on/off, traditional mechanical switches earned their reputation: familiar feel, simple wiring, reasonable cost. But LED lighting has raised the bar. Fixtures are slimmer, control boards are denser, and users expect a consistent, premium press - whether that's in a hotel corridor, a showroom, or a smart home panel. These realities expose three pain points that come up again and again:

• Tactile drift over time - the feel becomes mushy or inconsistent after thousands of presses

• Space pressure - crowded PCBs and tight enclosures leave little room for bulky hardware

• Energy discipline - systems run on low-current logic and can't waste power on the interface

A well-designed LED Push Button Tact Switch addresses each. The compact footprint frees panel space. Short, controlled travel produces a crisp, repeatable click. Low operating current supports aggressive energy targets in modern luminaires and controllers.

- Why Feel And Consistency Matter?

Users judge hardware by touch long before they read a spec sheet. In heavy-use applications - think control panels, signage, and accent lighting - the press must be reliable from the first day to the last. Hanxia designs for a stable operating force of 250 gf ± 50 gf and a controlled contact journey of 0.2 ± 0.1 mm. That balance creates confident actuation without finger fatigue and avoids accidental double-presses that frustrate end users and inflate support tickets.

Inside The Switch

Comparisons work best when numbers meet outcomes. Here's how critical parameters translate into real-world behavior for lighting and control systems that rely on low-voltage logic.

- Rating: 50 mA at 12 V DC - ideal for LED driver interfaces and microcontroller inputs; it keeps thermal stress down and simplifies layout.

- Contact resistance: ≤ 100 mΩ - cleaner signals, fewer micro-arcs, and reduced contact heating, which helps prevent LED flicker triggered by noisy inputs.

- Insulation resistance: ≥ 100 MΩ - limits leakage paths that can cause “ghost” illumination in sensitive LED circuits.

- Dielectric strength: 250 V, 50 Hz, 1 min - comfortable safety margin during compliance testing and transient events on commercial mains.

- Temperature: −20 °C to 80 °C; Humidity: ≤ 80% RH - reliable feel and actuation across seasonal swings, ceiling voids, utility rooms, and sheltered industrial sites.

- Lifetime: 50,000 cycles - sized for typical lighting interfaces; high-traffic installations can scale reliability with redundancy or usage profiling.

Traditional mechanical switches can certainly hit long lifetimes, but they often bring larger travel, bulkier bodies, and less predictable feel as components wear. A LED Push Button Tact Switch concentrates on electrical cleanliness - reducing bounce and maintaining consistent force - so the signal delivered to the controller is clear and repeatable. That steadiness shortens QA time, lowers return rates, and stabilizes the user experience across production batches.

Space, Thermal Headroom, And Efficiency In LED Systems

Lighting enclosures are getting smaller, drivers run warmer than before, and every cubic millimeter must do more work. Here the tact architecture shines:

- Compact design: Frees space for additional I/O, wireless modules, or larger copper pours that improve heat spreading.

- Low power draw: Keeps the user interface from adding to standby consumption, especially important for always-on smart lighting nodes.

- Thermal cooperation: Less bulk around hot components helps airflow and reduces hotspots near LED driver ICs and capacitors.

Where mechanical devices can feel robust but oversized, an LED Push Button Tact Switch supports modern layouts without sacrificing durability. That makes it easier to meet efficiency regulations and achieve longer service intervals.

- Built For LED Lighting Interfaces

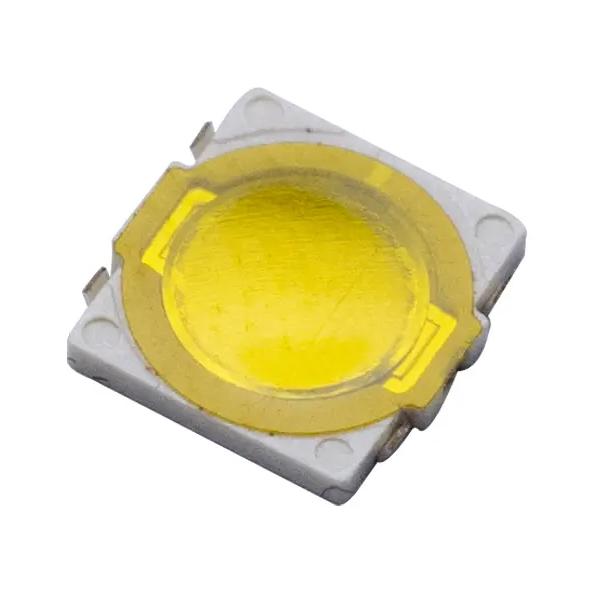

Hanxia's push button tact design with a high-visibility yellow film was developed specifically for LED lighting systems. The film improves target recognition under low ambient light and adds a clean, professional accent on the panel - useful in hotels, lobbies, theaters, or corridors where quick, error-free presses matter. Because the interface is touched by many hands, clear visual guidance reduces mis-presses and speeds interactions for staff and visitors alike.

Where It Fits Best:

• LED lighting systems - from home task lights to office fixtures and retail displays

• Lighting control panels - compact layouts, straightforward wiring, service-friendly access

• Residential and commercial - consistent feel reduces maintenance calls and user confusion

• Accent and decorative lighting - frequent presses demand tactile precision and stable feedback

- When A Mechanical Switch Still Makes Sense

There are cases where a classic mechanical device remains the right choice: higher current paths, large throw for emphatic feedback, or a need for very audible clicks. Many teams pair a mechanical interface with a relay or driver stage. The key is to make the decision based on space, current, and user-experience targets - not habit.

Selection Checklist And Practical Tips

To choose confidently between a mechanical part and a LED Push Button Tact Switch, start with the environment and the electrical envelope, then work forward to the user experience:

• Match the circuit: For logic-level LED control, 12 V DC at 50 mA is a practical baseline.

• Check conditions: −20 °C to 80 °C and ≤ 80% RH cover most indoor and light-industrial sites; verify extremes if you expect heat soak or humidity spikes.

• Validate tactility: Around 250 gf with short travel offers a crisp, gloved-hand-friendly press without accidental activation.

• Plan service life: 50,000 cycles fits typical lighting use; increase margin for 24/7 public interfaces.

• Protect signal quality: Favor low contact resistance and strong insulation to avoid flicker and ghosting in sensitive LED drivers.

• Optimize panel density: Use the smaller footprint to add status LEDs, sensors, or labeling without enlarging the enclosure.

The Hanxia Perspective - And Your Next Step

At Hanxia, we engineer LED Push Button Tact Switch solutions around real deployment needs, not just lab targets. Our development flow validates force curves, travel tolerance, contact resistance, and dielectric strength across temperature and humidity ranges. The result is a switch that feels right, uses power responsibly, and drops into compact designs without drama.

Call To Action

If you're rethinking your lighting controls - or finalizing a new fixture - talk to Hanxia. Request samples, share your load and environmental constraints, and ask for a quick DFM review. We'll help you decide when a LED Push Button Tact Switch makes the most sense, and how to integrate it so your product performs flawlessly from the very first press.