The Benefits of Latching Switches for Long-Term Operational Stability

In today's fast-paced business environment, reliability matters more than ever. A latching switch locks into its set position without the need for constant power. This feature reduces wear and energy costs. Many companies face downtime due to simple switch failures. Adopting a latching switch can prevent unplanned stops. It also ensures consistent performance under heavy use. Maintenance teams spend less time on repairs. Managers enjoy clearer budgets and fewer surprise expenses. Designers value the compact form factor and rugged design.

These switches suit industrial machinery, smart building systems, and remote monitoring setups. They excel where power savings and stability are critical. In the long run, businesses benefit from both efficiency gains and improved safety records. As systems grow more complex, choosing the right components can make all the difference. Investing in latching switch technology today paves the way for smoother operations tomorrow.

Market Demands for Long-Term Stability

Why Unplanned Downtime Hurts Profitability

Unplanned downtime leads to direct financial losses. Machines and systems that fail unexpectedly cause production delays and increased repair costs. This disrupts workflow and impacts deadlines, reducing customer satisfaction. Businesses must minimize these interruptions to stay competitive.

Common Failure Modes in Control Systems

Control systems often fail due to unreliable switches. Momentary contact switches, for instance, can lose their position, leading to system shutdowns. Such failures are costly in critical operations. The risk of these failures highlights the need for more reliable solutions, such as latching switches.

From Momentary to Latching: A Shift in Reliability

Latching switches provide a more reliable solution. Unlike momentary switches, they stay in their set position without needing continuous power. This ensures that systems remain stable and secure for longer periods, reducing the risk of failure and increasing operational stability.

How Latching Switches Secure Continuous Operation

Core Principle: Lock-In vs. Momentary Contact

The key difference between latching and momentary switches lies in their functionality. Latching switches “lock” into position once activated, maintaining the state until manually switched again. Momentary switches, on the other hand, only remain in their state while the button is pressed. Latching switches offer continuous, reliable operation.

Energy Savings Through Self-Holding Mechanisms

Latching switches are energy-efficient. They do not require constant power to maintain their position. Once activated, they hold the state with minimal energy consumption, making them ideal for long-term, low-energy operations. This leads to lower operational costs in power-hungry industries.

Eliminating False Triggers in Harsh Environments

Harsh environments often trigger false alarms in sensitive equipment. Latching switches, with their secure locking mechanism, avoid these false triggers. This makes them perfect for use in manufacturing or industrial environments where reliability is paramount, ensuring stable operations even under challenging conditions.

Key Technical Advantages of Latching Switches

Adjustable Sensitivity for Tailored Thresholds

Latching switches can be fine-tuned to meet specific operational needs. Their adjustable sensitivity settings allow businesses to customize thresholds. This ensures that the switch responds accurately, whether it's for high-precision industrial equipment or simple control systems.

Rugged Construction to Withstand Shock and Vibration

Built to last, latching switches are designed for tough environments. They are made with durable materials that can withstand shock, vibration, and extreme temperatures. This makes them ideal for machinery in heavy industries such as automotive or mining, where reliability and durability are crucial.

Fast Response and Low Power Draw

Latching switches offer a quick response time. They immediately lock into position without delay, which is essential in systems requiring fast action. Additionally, they have a low power draw, making them energy-efficient, perfect for applications where power conservation is vital.

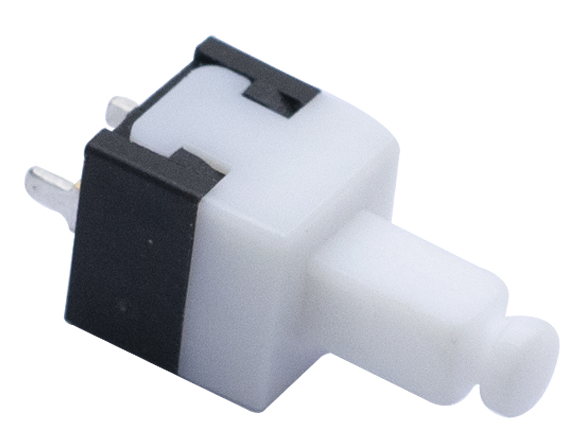

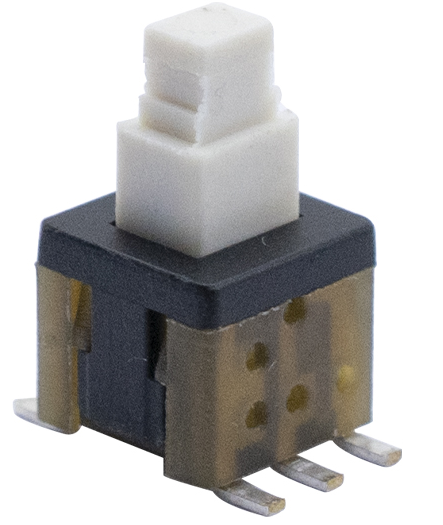

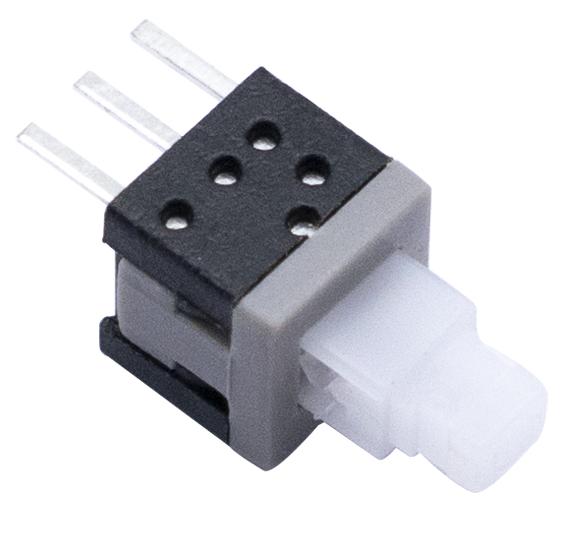

Hanxia's Latching Switch Portfolio

Product Line Overview and Certifications

Hanxia offers a wide range of latching switches designed to meet the needs of various industries. All our products are CE, RoHS, and ISO 9001 certified, ensuring they meet international quality standards. This guarantees high performance and safety, making our latching switches suitable for even the most demanding environments.

Automated Assembly and Strict Quality Control

At Hanxia, we utilize fully automated assembly lines to manufacture latching switches. This helps minimize human errors and ensures precision in every unit produced. Our strict quality control measures, including automated inspections, ensure that each latching switch performs reliably and meets all required specifications before reaching customers.

Customization Options

We understand that each business has unique needs. Hanxia's latching switches come with customizable features, such as adjustable pin counts and actuation forces. This flexibility allows businesses to tailor the switches to their specific applications, ensuring optimal performance and integration with existing systems.

Industry Applications Driving ROI

Industrial Machinery

In industrial machinery, latching switches play a vital role in ensuring operational stability. They are commonly used in pumps, compressors, and conveyors, where continuous operation is essential. These switches reduce downtime and prevent system failures, contributing to increased productivity and cost savings for businesses.

Smart Buildings and Remote Monitoring Systems

Latching switches are also integral to smart buildings and remote monitoring systems. Their ability to hold a set position without constant power makes them ideal for controlling lighting, HVAC systems, and security devices. With reliable operation, these switches ensure energy efficiency and long-term reliability in smart building systems.

Automotive and Heavy Equipment Use Cases

In automotive and heavy equipment industries, latching switches are used in a variety of applications, from engine control systems to safety mechanisms. Their durability and performance under extreme conditions make them indispensable for maintaining the safety and reliability of vehicles and heavy machinery, ensuring smooth operations in tough environments.

Integrating Latching Switches for Future Growth

Best Practices for Panel Design and Wiring

When integrating latching switches into your systems, it's important to follow best practices for panel design and wiring. Proper wiring ensures the longevity and performance of the switches. Clear labeling and organized wiring also reduce troubleshooting time and help streamline maintenance efforts.

Partnering with Hanxia for Technical Support and Training

At Hanxia, we provide full technical support and training for businesses adopting our latching switches. Our team ensures that your staff understands installation and maintenance procedures, empowering you to maximize the benefits of our products and keep systems running smoothly.

Emerging Trends: IoT-Enabled Switch Monitoring

The future of latching switches is closely tied to IoT-enabled monitoring systems. These innovations allow businesses to remotely monitor the status of switches, predicting failures before they occur. With IoT integration, businesses can make data-driven decisions to further optimize operations and reduce downtime.

Unlock Stability and Efficiency with Hanxia's Latching Switches

Ready to boost your operational reliability? Explore Hanxia's high-performance latching switches today. Contact us to learn more about our customizable solutions and how we can help drive your business towards greater efficiency and cost savings.