A Comprehensive Analysis of the Best Alternatives

In the last 15 years of designing industrial networks, I’ve seen the landscape change dramatically. There was a time when "reliability" simply meant buying the most expensive blue or yellow box you could find, paying a premium for the logo, and hoping for the best.

But today, with supply chains stretched thin and budget scrutiny at an all-time high, the equation has changed. I’ve spoken with countless plant managers who are frustrated by 50-week lead times from major incumbents like Cisco or Moxa. They are asking a critical question: Are there reliable alternatives that don't compromise on quality?

The answer is yes. But you have to know what you’re looking for. In 2025, reliability isn't defined by a brand name; it's defined by engineering specifications, chipset quality, and rigorous testing standards.

If you are looking to optimize your industrial network infrastructure without the "brand tax," this analysis is for you.

Why Industry Leaders Are Seeking Alternatives

The shift away from Tier-1 giants isn't just about saving money—though the savings are significant. It’s about agility and pragmatism.

When a production line is down, you cannot wait six months for a replacement switch. Specialized manufacturers have carved out a critical niche by offering significantly shorter lead times—often weeks instead of months. This agility is a massive competitive advantage for system integrators who need to deploy projects on schedule.

The "Over-Engineering" Trap

A common realization I see among engineers is that they are paying for features they never use. Why pay for a complex Layer 3 enterprise license when your application only requires a robust Layer 2+ DIN-rail switch for a machine cell?

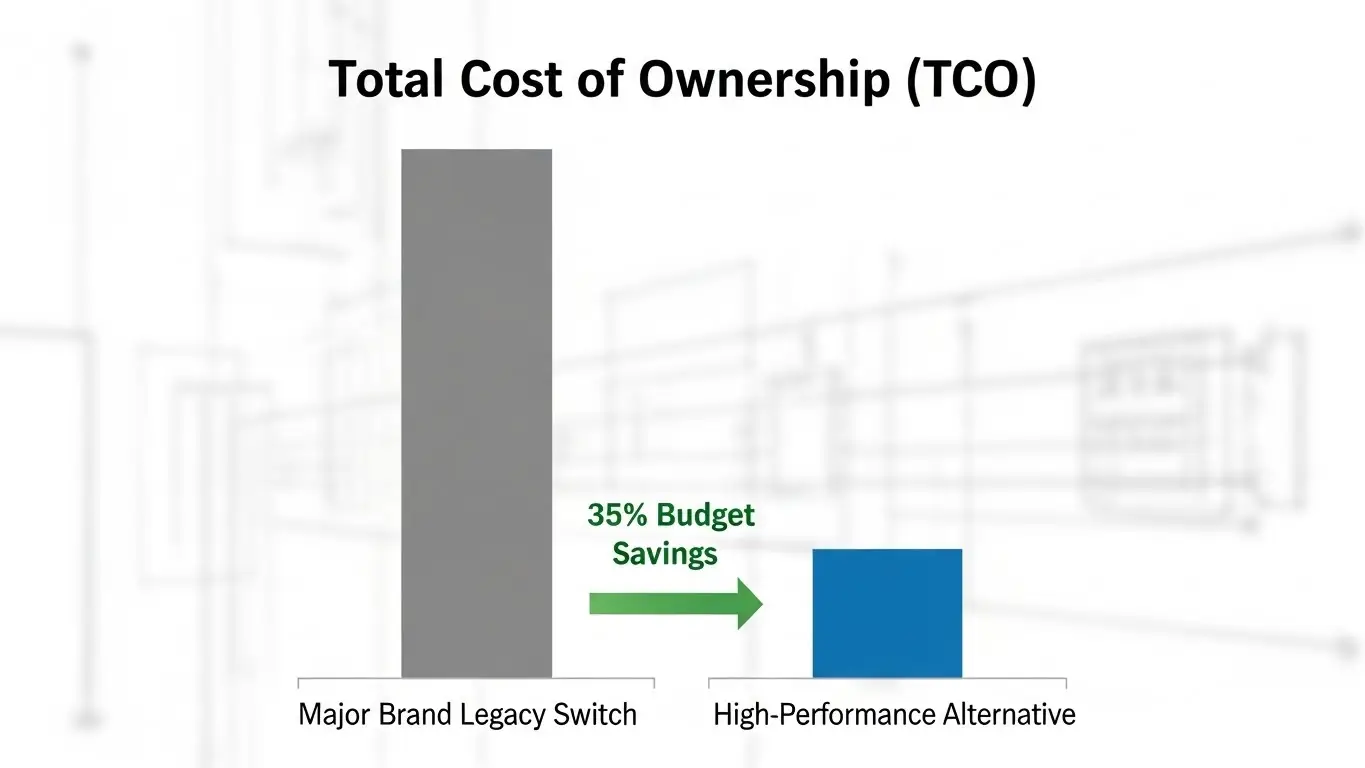

By switching to high-performance alternatives, manufacturing firms are seeing budget reductions of 30-40% without sacrificing compliance with essential standards like ISO/IEC or UL certifications.

Visual Recommendation: A bar chart comparing "Cost per Port" between a major incumbent brand and a specialized industrial alternative, highlighting the 35% average savings.

Critical Criteria for Evaluating Alternatives

When we evaluate alternatives at HX-Switch, we look past the marketing fluff and go straight to the datasheet. To ensure a switch can survive on a factory floor, it must meet three non-negotiable criteria.

1. Environmental Hardening

Commercial switches are built for air-conditioned offices (0°C to 40°C). Industrial alternatives must withstand the brutal reality of the plant floor.

- Operating Temperature: Look for a standard range of -40°C to 85°C. This ensures the capacitors and silicon won't fail during a summer heatwave or a winter freeze in an unheated cabinet.

- IP Rating: An IP30 or IP40 metal casing is essential. Plastic casings have no place in an industrial cabinet where electromagnetic interference (EMI) is rampant.

2. Power Stability and Redundancy

In my experience, the power supply is the most common point of failure. A reliable industrial alternative will always offer dual redundant power inputs. If Power Source A fails (or a breaker trips), the switch automatically pulls from Power Source B with zero packet loss.

For surveillance and sensor networks, check the PoE budget carefully. You need a switch that guarantees the full IEEE 802.3at (30W) or 802.3bt (60W-90W) output even when temperature rises.

3. Network Resilience Protocols

If a cable gets cut by a forklift, how fast does your network recover?

- Standard Spanning Tree (STP/RSTP): Good for simple loops, but recovery can take seconds.

- ERPS (Ethernet Ring Protection Switching): The gold standard for industrial rings. It offers recovery times of <20ms, ensuring that your PLCs and SCADA systems don't even register the glitch.

Visual Recommendation: A checklist graphic titled "Industrial Grade Checklist" comparing 'Office Grade' vs 'Industrial Grade' specs (Temp, Vibration, Power Input).

Managed vs. Unmanaged: Choosing the Right Architecture

One of the most frequent questions I get is, "Do I really need a managed switch?" The answer depends entirely on your visibility needs.

The Unmanaged Alternative

Best for: Isolated machine cells and simple plug-and-play connectivity. Unmanaged switches are the workhorses of the industry. They are transparent to the network—data goes in, data goes out. There is no IP address to configure and no software to update. If you simply need to connect five IP cameras to an NVR, an unmanaged high-power PoE switch is often the most robust and cost-effective choice.

The Managed Alternative

Best for: Plant-wide networks, motion control, and critical infrastructure. If you need to segment traffic using VLANs (e.g., keeping office data separate from machine control data) or if you need to know immediately when a link goes down via SNMP traps, you need a managed switch.

For a deeper dive into specific model capabilities, you can explore our detailed industrial switch comparisons.

Top Alternative Categories by Use Case

1. High-Density PoE Solutions

For modern factories deploying IIoT sensors and 4K security cameras, power is king. Alternatives in this space are now offering high-density ports (16-24 ports) with massive power budgets that rival the big names. We are seeing a huge demand for switches that support IEEE 802.3bt (90W) to power heavy-duty PTZ cameras and digital signage directly over Ethernet.

2. Fiber Optic Long-Haul Connectivity

Copper cables have a hard limit of 100 meters. For connecting a warehouse to a main office, fiber is the only viable option. Alternative manufacturers often provide more flexible SFP slot configurations (like 2 Gigabit SFP + 8 Copper) allowing you to daisy-chain switches across kilometers without signal degradation.

3. Compact DIN-Rail Solutions

Cabinet space is real estate. Many legacy switches are bulky. Newer alternatives focus on high port density in slim aluminum housings that snap directly onto a standard 35mm DIN rail, leaving more room for your power supplies and terminal blocks.

The HX-Switch Advantage: Beyond the Datasheet

At HX-Switch, we believe that trust is earned through transparency. While many "white box" vendors simply ship products, we follow a rigorous engineering validation process that mirrors (and often exceeds) industry giants.

100% Burn-In Testing

We don't do spot checks. Every single unit that leaves our facility undergoes a 12 to 24-hour burn-in test in an aging chamber. We stress the units at high temperatures and full data load to trigger any early component failures before they reach your facility.

Customization at Scale

Try asking a Tier-1 vendor to modify a port configuration or change a firmware default for an order of 50 units. It won't happen. As a specialized manufacturer, we offer the flexibility to tailor solutions—whether that’s specific fiber connectors or pre-configured VLAN settings—to save you hours of installation time.

ROI Analysis: The Cost of Switching

Let's talk numbers. The "safe choice" of buying a big brand often comes with a hidden cost: the cost of waiting and the cost of inflexibility.

Capital Expenditure (CapEx): You typically save 30% upfront on hardware. For a mid-sized plant upgrade requiring 50 switches, that can easily equal $15,000 - $20,000 in immediate savings.

Operational Expenditure (OpEx): High-quality alternatives use fanless, low-power chipset designs. This eliminates the #1 mechanical failure point (the cooling fan) and reduces energy consumption over the device's 10-year lifespan.

However, the biggest number to consider is the Cost of Downtime. In automotive and heavy manufacturing, downtime costs can average $22,000 to $50,000 per minute. If an "alternative" switch has a higher MTBF (Mean Time Between Failures) because it uses superior, newer silicon compared to a 5-year-old legacy model, the ROI isn't just in the purchase price—it’s in the uptime.

Conclusion

The era of defaulting to the most famous logo is over. Smart manufacturing demands smart procurement.

Reliability is not magic; it is physics and engineering. It is a wide operating temperature range, dual power inputs, and high-quality gold-plated pins. By choosing a high-performance alternative, you aren't just saving budget—you are often gaining agility and getting access to newer, more efficient technology.

If you are ready to audit your network spend and test a solution that prioritizes performance over marketing, we are here to help.

Frequently Asked Questions (FAQ)

Yes. Industrial Ethernet standards (IEEE 802.3) are universal. A switch from HX-Switch will communicate seamlessly with devices from Cisco, Moxa, or Siemens. You can mix and match brands within the same network without issues, provided your VLAN and ring protocols are configured correctly.

The main differences are durability and power reliability. Industrial PoE switches are built with rugged metal casings, are rated for extreme temperatures (-40°C to 85°C), and often feature redundant power inputs. Commercial switches typically use plastic or light metal casings and are rated only for office temperatures (0-40°C).

Modern unmanaged industrial switches utilize "Store and Forward" switching architecture with large backplane bandwidth. This ensures they can handle full wire-speed traffic on all ports simultaneously without dropping packets, even in data-heavy video surveillance applications.

Yes. Almost all our industrial-grade switches feature a terminal block with inputs for two separate DC power sources (PWR1 and PWR2). If one power supply fails, the switch instantly switches to the backup source, ensuring zero downtime.

While commercial switches often come with 1-year warranties, high-quality industrial alternatives typically offer 3 to 5-year warranties. This reflects the higher quality of components, such as industrial-grade capacitors and processors, used in their construction.