How IP67 Waterproof Rating Works for Tact Switches

An IP67 waterproof rating on a tact switch indicates that the component is totally protected against dust ingress and can withstand being submerged in water up to 1 meter deep for 30 minutes.

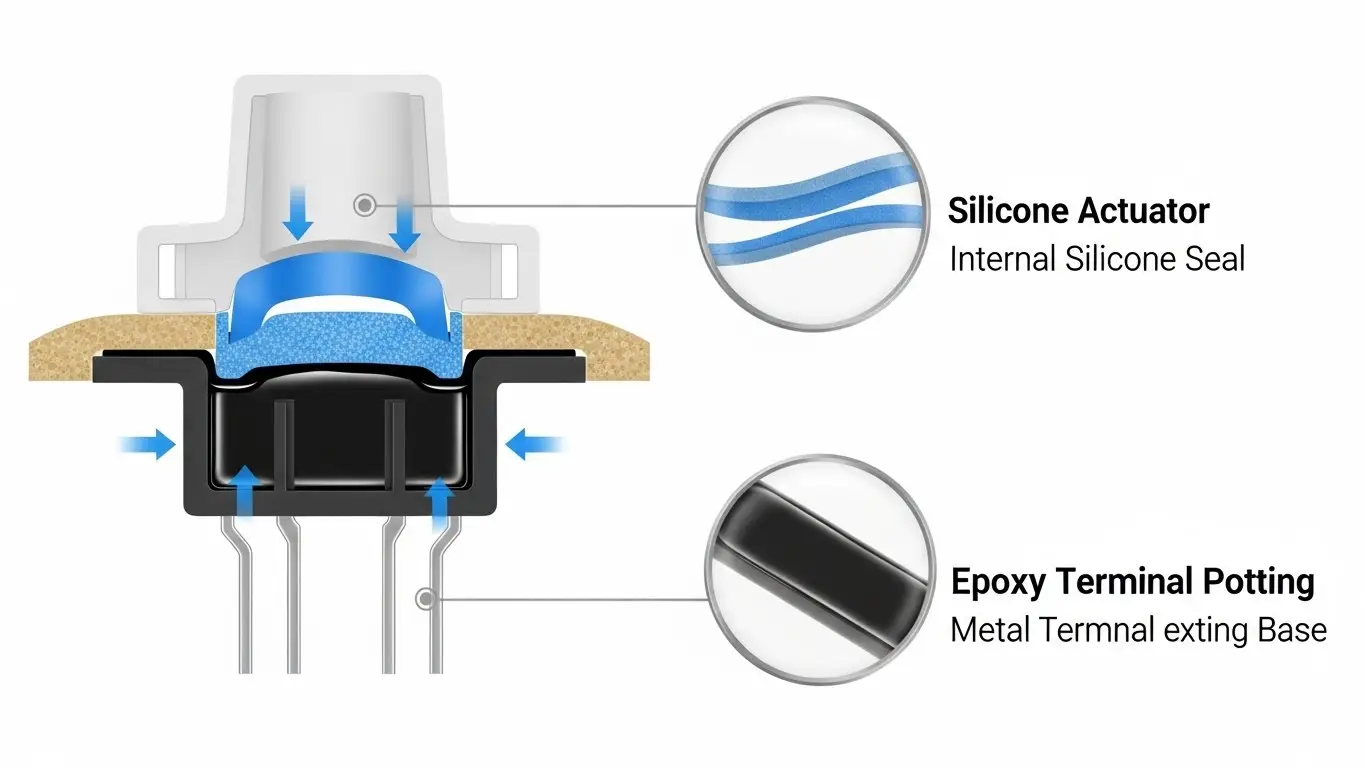

For engineers, this rating (often called "process sealed") serves two distinct purposes. First, it ensures the switch survives the harsh PCB washing process after soldering, where flux residue is cleaned off using solvents or water jets. Second, it protects the final product—like an outdoor smart meter or a wearable medical device—from rain, sweat, and accidental drops in water. Unlike standard switches that allow air and contaminants to flow freely, IP67 switches utilize internal silicone seals, adhesive membranes, or epoxy potting to create a hermetic barrier around the electrical contacts.

Decoding the IP Rating System

The "IP" stands for Ingress Protection. The two digits following it are not random; they are specific classifications defined by the IEC 60529 standard.

The First Digit (6): Solid Particle Protection

The number 6 represents the highest level of solid protection. It means the switch is dust-tight. No ingress of dust is permitted, even after an extended vacuum test. This is critical for industrial controls where conductive metal dust or sawdust could short-circuit a standard open switch.

The Second Digit (7): Liquid Ingress Protection

The number 7 indicates protection against the effects of temporary immersion.

- Depth: 15 centimeters to 1 meter.

- Time: Up to 30 minutes.

It is important to note that IP67 does not guarantee protection against high-pressure water jets (that requires IP65 or IP66) or continuous deep submersion (that requires IP68).

How Do Manufacturers Make Tact Switches Waterproof?

Achieving an IP67 rating in a component as small as 6x6mm requires precise internal engineering. Manufacturers typically use one of three sealing methods.

1. Silicone Rubber Actuators (Internal Stem)

This is the most common method for "soft feel" switches. The hard plastic plunger is replaced or covered by a flexible silicone rubber stem. This rubber component acts as a gasket, compressing against the switch housing to create a watertight seal while still allowing the force to transfer to the metal dome.

Note on Haptics: Adding a rubber seal often changes the tactile feedback. As detailed in our guide onhow tact switch actuation force works, rubber actuators can dampen the sharp "snap" of the metal dome, resulting in a softer, quieter click.

2. Adhesive Membrane Seals

For low-profile switches where there is no room for a rubber gasket, manufacturers use a thin, high-strength adhesive film (often Polyimide or Polyester) directly over the metal dome. This film is laser-welded or bonded to the plastic base, trapping the dome inside a sealed air pocket.

3. Terminal Potting (Base Sealing)

Water doesn't just enter from the top; it can wick up through the bottom terminals via capillary action. To prevent this, especially during wave soldering, manufacturers apply a layer of epoxy resin (potting) around the base of the metal terminals.

IP67 vs. IP68: What Is the Difference?

Many engineers mistakenly assume IP68 is just "better" than IP67, but they have different testing criteria.

| Feature | IP67 Rating | IP68 Rating |

| Definition | Temporary Immersion | Continuous Submersion |

| Depth | Up to 1 meter | >1 meter (Manufacturer Specified) |

| Time | 30 Minutes | Continuous (Manufacturer Specified) |

| Common Use | PCB Washing, Rain Exposure | Underwater Cameras, Marine Gear |

| Cost | Moderate | High |

If your device needs to operate while underwater (like a diving watch), IP67 is insufficient. However, for most consumer electronics, IP67 provides the necessary "accidental drop" protection.

Can You Wash IP67 Switches After Soldering?

Yes, IP67 switches are specifically designed to be "process sealed" or "washable."

In automated PCB assembly, boards are often passed through a cleaning stage to remove corrosive flux residues. A standard open switch would absorb the washing fluid, trapping it inside the dome area. This fluid would eventually dry, leaving behind sticky residue that causes contact failure.

IP67 switches prevent this ingress. However, you must adhere to the manufacturer's washing guidelines:

- Temperature: Do not wash immediately after reflow; let the switch cool to room temperature to prevent the vacuum effect from sucking in fluid.

- Agents: Avoid harsh chemicals that degrade silicone seals.

For a broader understanding of how these switches fit into complex assemblies, you might want to read our Micro Switch Deep Dive.

Does Waterproofing Affect Lifespan?

Generally, yes, but in a positive way.

While the rubber seal might wear out over time, the protection it offers keeps the contacts clean. A major cause of switch failure is silver migration and sulfurization of the contacts caused by humidity and air pollution. By sealing the contacts, you effectively delay these corrosion processes.

However, mechanical wear still applies. As discussed in Tact Switch Lifecycle Ratings Explained, the silicone seal itself has a fatigue limit. If the rubber tears after 500,000 cycles, the waterproof rating is lost, even if the switch still clicks electrically.

Are IP67 Switches Suitable for Underwater Use?

No, IP67 switches are not intended for active operation underwater.

Actuating (pressing) a switch while it is submerged creates a dynamic pressure spike that can force water past the seals. IP67 tests are static—the switch is gently lowered into water and left alone.

If your application requires the user to press buttons while submerged (e.g., a waterproof camera housing), you typically need a specialized magnetic (reed) switch or a piezoelectric switch, rather than a standard mechanical momentary or latching tact switch.

Frequently Asked Questions

No. Seals degrade over time due to UV exposure, temperature cycling, and mechanical wear. An IP67 switch might degrade to IP54 (splash proof) after several years of heavy use outdoors.

You can use conformal coating to protect the PCB, but you cannot coat the switch itself. The coating liquid would seep into the switch mechanism and glue the parts together, destroying the tactile feel. You must use a sealed switch if you plan to coat the board.

IP65 protects against low-pressure water jets (like a nozzle). IP67 protects against immersion. Interestingly, a device can be IP67 (immersion safe) but fail IP65 (jet safe) tests because the pressure dynamics are different.

Not automatically. While the membrane layer itself is waterproof, the adhesive edges must be perfectly sealed to achieve an IP67 rating. Standard membrane keypads are often only IP54 (dust and splash protected).

Reputable manufacturers will provide a test report verifying the switch meets IEC 60529 standards. Look for "Sealed" or "Process Sealed" in the datasheet features.

Key Takeaways

- Definition: IP67 means dust-tight and safe for 30 minutes in 1 meter of water.

- Process Sealed: These switches are essential if your PCB manufacturing line involves a washing phase.

- Feel: The internal silicone seals often make the switch feel slightly softer than non-sealed variants.

- Limit: Do not use IP67 switches for continuous underwater operation; they are for accidental exposure protection.

Conclusion

Selecting an IP67 waterproof tact switch is a smart insurance policy for your product's longevity. Whether you are protecting against the immediate threat of PCB washing solvents or the long-term threat of outdoor humidity, the small additional cost of a sealed switch pays for itself by preventing field failures.

If you are designing for a harsh environment, always check the specific "sealing material" in the datasheet to ensure it is compatible with your expected chemical or temperature exposures.