How Gold-Plated Contacts Improve DIP Switch Life

Gold-plated contacts improve DIP switch life by preventing oxidation, ensuring reliable signals in low-voltage "dry circuits." Unlike tin or silver, gold is a noble metal that does not corrode or form an insulating oxide layer.

For engineers, the choice is simple: if you are switching logic-level signals (under 100mA / 20V), specifically in modern 3.3V or 1.8V IoT devices, gold plating is essential. It guarantees that even a weak signal passes through the switch without needing high voltage to "punch" through surface tarnish. However, gold is not a magic bullet; it is soft and thin, making it unsuitable for high-power switching where arcing can vaporize the plating.

The Enemy: Why Do Switches Fail?

To understand why gold is superior, you must understand how standard switches fail.

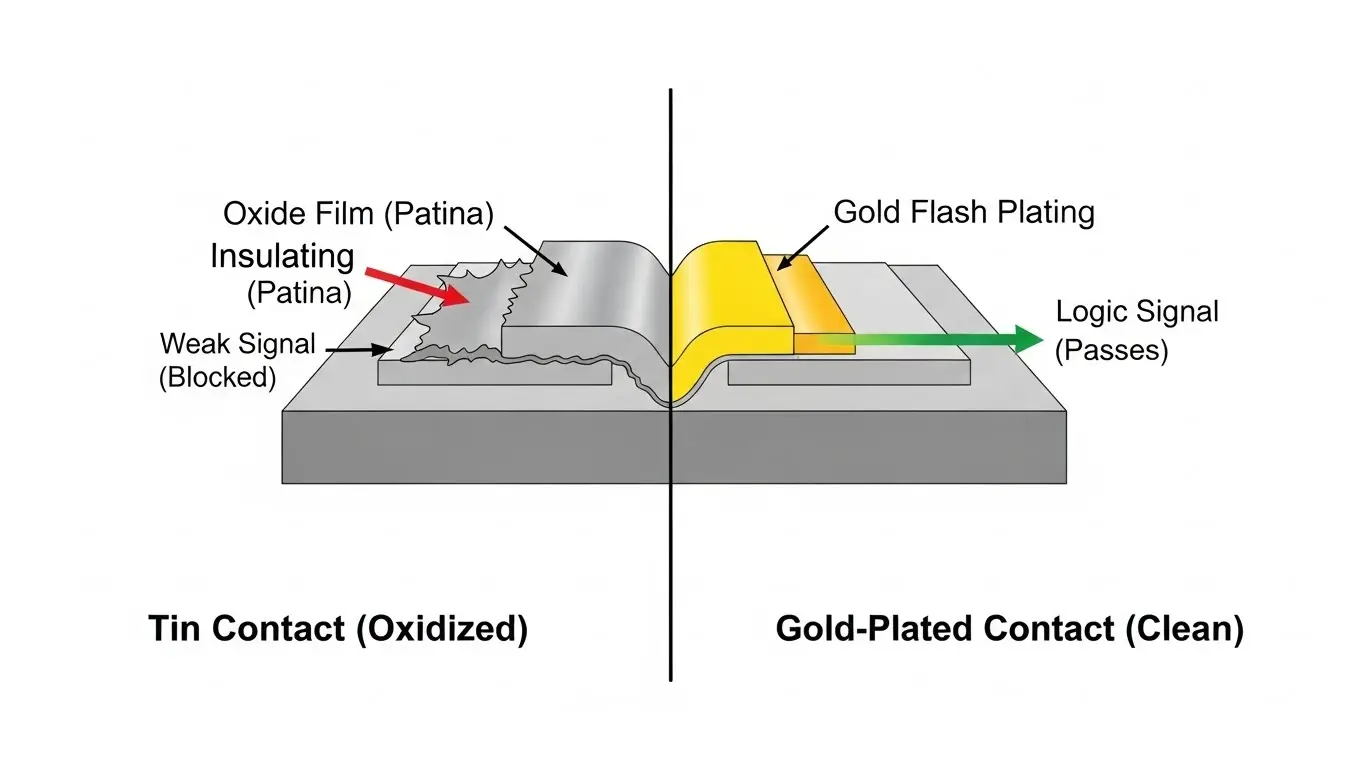

Most standard DIP switches use Tin or Silver-Nickel contacts. While excellent conductors, they react with oxygen and sulfur in the air to form a thin, non-conductive film (patina).

In high-voltage circuits (like 24V industrial lines), this isn't a problem. When the switch closes, the electrical potential is strong enough to arc through the microscopic oxide layer—a phenomenon called "Wetting Arc." It literally burns the rust away to make a connection.

The "Dry Circuit" Problem

In modern electronics, we rarely use 24V. We use 3.3V microcontrollers or 1.8V FPGA logic.

These low-energy circuits lack the "punch" to break through the oxide layer on a tin contact. You might close the switch physically, but the signal stays open electrically. This is a Dry Circuit failure.

Gold plating solves this because it does not oxidize.

- Shelf Life: A gold-plated DIP switch can sit in a warehouse for 5 years and work perfectly on the first toggle.

- Reliability: It requires almost zero wetting current, making it the only viable choice for battery-powered logic.

Gold vs. Tin: The Engineering Trade-off

Choosing the right plating isn't just about "premium vs. cheap"; it's about matching the material to the load.

| Feature | Gold-Plated Contacts | Tin / Silver Contacts |

| Best Application | Logic Level (0-20V, <50mA) | Power Level (>20V, >100mA) |

| Oxidation Resistance | Excellent (Noble Metal) | Fair (Forms Oxide Layer) |

| Contact Resistance | Extremely Low & Stable | Varies (Increases with Age) |

| Cost | High | Low |

| Wetting Current Req. | Negligible | Moderate (Needs ~10V punch) |

| Mechanical Wear | Poor (Soft, wears off fast) | Good (Harder material) |

For a deeper look at how voltage levels dictate component choice, refer to our DIP Switch Current & Voltage Rating Guide.

When Should You AVOID Gold?

It sounds counterintuitive, but Gold is the wrong choice for high-power switching.

Gold plating on DIP switches is typically "Gold Flash"—a layer only 0.05 to 0.1 microns thick over a nickel base. If you use a gold switch to control a 24V solenoid or a high-current fan:

- Arcing: The switching arc vaporizes the thin gold layer instantly.

- Contamination: The underlying metal is exposed, leading to rapid corrosion.

- Welding: The soft gold can micro-weld under high heat, sticking the switch in the closed position.

For these power applications, standard Tin is superior because it is harder and thicker.

Environmental Stability & Fretting

DIP switches are often used in "Set and Forget" scenarios. They might be configured once and then left alone for 10 years.

In environments with temperature swings, materials expand and contract. This causes the switch contacts to rub against each other microscopically, a process called Fretting. On tin contacts, this rubbing creates abrasive oxide dust that eventually blocks the signal. Gold acts as a lubricant, preventing this fretting corrosion.

If your device operates in humid or harsh environments, pairing gold contacts with a sealed housing is critical. As explained in our IP67 Waterproof Rating Guide, keeping sulfur and moisture out of the switch body further extends the advantage of the gold plating.

How Plating Affects Lifecycle Ratings

While gold prevents corrosion, it doesn't necessarily increase the mechanical cycle life (the number of clicks). In fact, because gold is soft, it can wear away mechanically if the contact pressure is too high.

However, "Lifecycle" is defined by resistance stability. Since gold maintains low resistance (under 50mΩ) longer than oxidizing tin, it effectively extends the Electrical Lifecycle in logic applications.

- Tin Failure Mode: Resistance creeps up until the signal is lost.

- Gold Failure Mode: Plating wears through to the nickel base.

For more on reading these specs, check our guide on Tact Switch Lifecycle Ratings.

Frequently Asked Questions

No. "Gold Flash" is a very thin cosmetic or protective layer used on most DIP switches. "Hard Gold" contains cobalt and is much thicker, used for high-wear items like PCB edge fingers or USB connectors. DIP switches rarely use hard gold due to cost.

It depends on the current. If it is a 12V signal to an ECU (low current), gold is excellent. If it is driving a 12V relay coil directly (high inductive load), stick to silver or tin to avoid pitting.

Yes. Gold dissolves into solder very quickly. If the gold layer is too thick, it can cause "Gold Embrittlement" in the solder joint, making it brittle. However, the thin flash on DIP switches typically doesn't cause this issue. Ensure your PCB Layout is optimized for proper wetting.

If a gold switch fails, it is usually due to "cold switching" contamination (dust getting inside) or because it was subjected to a voltage spike that damaged the plating.

Rule of thumb: If your circuit runs on a battery (3V) or uses a microcontroller input pin, pay the extra for Gold. If you are turning on a motor or light bulb (>100mA), save money and use Tin.

Key Takeaways

- Low Voltage Necessity: Gold is mandatory for 3.3V and 1.8V logic circuits to prevent dry circuit failure.

- Oxidation Immunity: Gold extends the shelf-life and "set-and-forget" reliability by resisting tarnish.

- Not for Power: Avoid gold for switching loads >100mA; the arc will destroy the plating.

- The Investment: The marginal cost increase for gold is cheaper than a field service call for a failed contact.

Conclusion

Gold-plated contacts are the insurance policy for modern digital electronics. While standard tin switches have their place in power circuits, the reliability of gold-plated DIP switches is unmatched for logic-level applications. By eliminating the risk of oxidation and ensuring instant signal conduction without wetting currents, gold plating ensures your device works exactly as configured, even after years of dormancy.

When selecting your next component, check the "Contact Material" section of the datasheet carefully—your microcontroller's ability to read that switch depends on it.