Why Modern Electric Button Switch Designs Improve Safety

Electric Button Switch upgrades fix problems that quietly erode margins and customer trust. From a manufacturer's vantage point at Hanxia, we see the same patterns across consumer devices: an inconsistent “click,” contact wear that shows up too soon, and batch-to-batch variation that slows lines and triggers rework. Moving to a modern switch brings the feel back under control, stabilizes test results, and makes production more predictable. Below, we lay out the business case, the product details, and the manufacturing backbone that make an upgrade worth doing now.

The Business Case for a Modern Electric Button Switch

Users judge a device the moment their thumb meets the button. If the feedback is mushy, loud, or late, the entire product feels unrefined. Older components also stumble when heat, vibration, or electrical noise enter the picture - issues that surface as returns and support tickets. A modern Electric Button Switch brings back a crisp, repeatable actuation and helps your engineering and operations teams speak the same language: consistent force, tight tolerance, stable insulation resistance.

For procurement and supply-chain managers, the benefit is equally practical. A single switch platform that spans appliances, audio gear, wearables, and controllers trims SKUs and simplifies vendor management. Fewer exceptions mean faster approvals, fewer last-minute substitutions, and easier forecasting. Design teams win, too. When actuation force and dielectric strength land where you expect, validation becomes routine instead of experimental.

✅ Common Pain Points You Can Eliminate

- Premature wear that dulls the “click” and lowers perceived quality

- Force variability that complicates assembly torque settings and QA limits

- Marginal dielectric strength in demanding or noisy environments

- Thermal drift that weakens feedback in hot or cold conditions

CTA: If your current switch is creating noise in your metrics - higher RMA, longer debug cycles - ask Hanxia for a quick, no-obligation fit check. We'll map your targets to a compatible Electric Button Switch and share sample timelines.

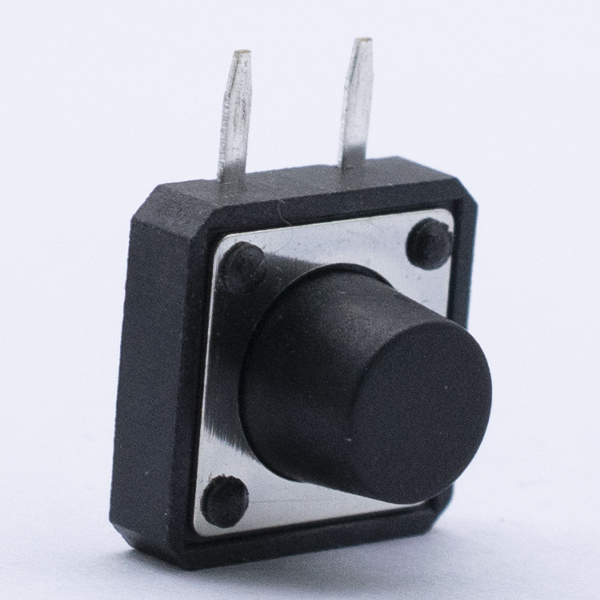

Inside Hanxia's TS128B2J: Built for Everyday Devices

At the center of our lineup is the Push Button Switch 12×12 for Consumer Electronics, item Tactile switch TS128B2J 250GF 290. It's designed for precise, durable performance in real conditions, not just on a bench. Engineers choose it for a steady, tactile response; operations teams like how it behaves the same way on Monday morning as it does on Friday night. If your search includes the long-tail phrase tactile electric button switch 12x12, the TS128B2J fits without forcing a layout rethink.

The TS128B2J is a match for the everyday interfaces that define user experience. In home appliances - think washing machines, microwaves, and refrigerators - it delivers reliable presses through repeated daily use. In televisions and audio systems, it supports power, input, and volume controls with a dependable feel. It also works in smartphones and tablets that need clear tactile feedback, in personal electronics such as smartwatches and wearables, and in remote controls where long service life matters. For gaming consoles and accessories, the switch handles rapid, repetitive actuation while keeping performance consistent.

✅ Core Specifications That Matter

- Operating Temperature: −20 to 80 ℃ for real-world thermal headroom

- Insulation Resistance: ≥100 mΩ to keep signals clean and predictable

- Operating Force: 70 gf ± 30 gf for a crisp, confident press

- Dielectric Strength: 250 V, 50 Hz, 1 min to endure demanding use cases

These figures translate to fewer surprises in validation and a smoother path through certification. In practice, they also mean the “feel” you approved in EVT is still there when the first thousand units roll off the line. If you need a push button switch for consumer electronics that scales from entry to premium SKUs, this profile gives your roadmap some welcome stability.

✅ Where It Fits in Your Roadmap

Use the TS128B2J to standardize your input strategy across product families. The consistent click helps align brand perception; the stable electrical behavior reduces late-stage troubleshooting. Because the switch suits multiple categories - from appliances to controllers - you can consolidate buys and reduce end-of-life risk on niche components.

CTA: Ready to evaluate? Contact Hanxia for samples or a short design review. We'll verify fit, feel, and reliability against your test plan and provide guidance on assembly fixtures and inspection points.

Why Hanxia De-Risks Your Upgrade

Upgrading an Electric Button Switch is not just a component decision; it's a factory decision. Hanxia has manufactured electronic components since 2014 and serves 7,500+ customers across the U.S., Germany, South Korea, Taiwan, and Hong Kong. That breadth shows up in our repeatability, our support structure, and our ability to scale without drama.

We run 38 fully automated production lines that prioritize consistency and throughput. Automation compresses cycle times and helps keep tolerances tight from reel to reel. Our daily capacity exceeds 2 million units, which means line ramps and seasonal peaks are supported without straining lead times. In cooperation with Korean partners, we use fully automatic assembly to reduce handling errors and improve part accuracy from the start. To make your planning simpler, we back delivery with a 90-day return policy.

✅ Capacity, Automation, and Delivery You Can Plan Around

- 38 automated lines for consistent, high-volume builds

- 2+ million units per day to support large orders

- Fully automatic assembly with Korean partners for better accuracy

- 90-day return policy for worry-free delivery planning

✅ Quality Assurance You Can Audit

Quality is checked end-to-end - from incoming materials through final inspection - and every switch is 100% factory-tested before shipment. For your team, that means shorter incoming inspection and fewer pauses on the line. It also means your field data stays boring in the best possible way: stable actuation, steady resistance, predictable lifetime.

CTA: Planning a control-panel refresh or a new handheld? Talk to Hanxia's engineering team about migrating to a modern Electric Button Switch without changing your industrial design or user-experience goals.

Final Thought

Upgrading to a modern Electric Button Switch is a practical, low-risk way to lift perceived quality and streamline production. Reach out to Hanxia for samples, quotes, or a rapid fit assessment and move your next build forward with confidence.