DIP Switch vs Toggle Switch: The Engineer’s Guide to PCB Control

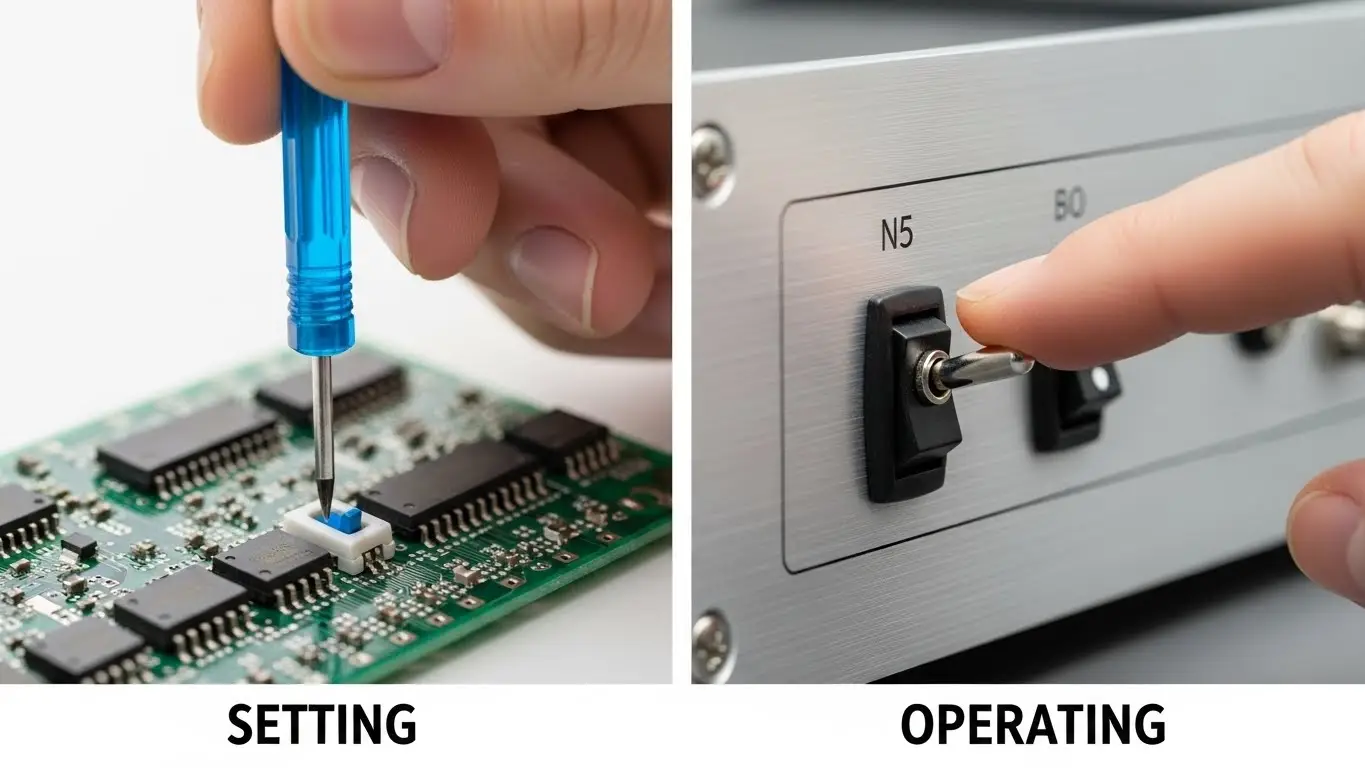

When designing a Printed Circuit Board (PCB) or a control panel, the choice between a DIP switch and a Toggle switch usually comes down to one question: How often does this switch need to be moved?

- Choose a DIP Switch for configuration. It is designed for "set and forget" applications (like device addresses or baud rates) where space is premium and changes are rare.

- Choose a Toggle Switch for operation. It is designed for frequent human interaction (like On/Off power controls), offering tactile feedback and higher current handling capabilities.

Below, we break down the engineering mechanics, durability, and use cases to help you finalize your Bill of Materials (BOM).

The Fundamental Difference: Configuration vs. Control

While both components break or complete a circuit, their design intent is vastly different.

The DIP Switch (Dual In-Line Package)

A DIP switch is actually a bank of electromechanical switches packaged together. You typically need a small tool or a fingernail to actuate them.

- Primary Use: Configuring device settings before installation.

- Key Feature: High density. You can fit 8 or 10 switches (poles) in the space of a single toggle switch.

- The Trade-off: They are not ergonomic. They are not meant to be flipped daily.

The Toggle Switch

A toggle switch uses a projecting lever (the actuator) that is moved up or down.

- Primary Use: Real-time control by a human operator.

- Key Feature: Tactile feedback. You can feel the "snap" when the state changes, which is vital for user interfaces.

- The Trade-off: They consume significant vertical space and panel real estate.

Technical Showdown: Specs at a Glance

For a quick decision, compare the standard specifications below.

| Feature | DIP Switch | Toggle Switch |

| Cycle Life | Low (1,000 - 3,000 cycles) | High (30,000 - 100,000+ cycles) |

| Current Rating | Low (25mA - 100mA) | High (1A - 20A+) |

| Voltage | Logic Level (5V, 12V, 24V DC) | Power Level (120V/240V AC capable) |

| Actuation | Tool or fingernail required | Finger lever (easy actuation) |

| Density | High (Multi-pole in one unit) | Low (Usually 1-4 poles per unit) |

| Cost | Low per circuit | Higher per unit |

Deep Dive: When to Use a DIP Switch

DIP switches are the standard for static parameters. If you are manufacturing a garage door opener, a remote control receiver, or an industrial sensor, you need a way to set a unique frequency or ID code.

Because these settings might only change once every few years (or never), durability is less critical than space efficiency.

Types of DIP Switches

- Slide DIP: The most common standard. Simple sliding actuators.

- Rotary DIP: Allows you to select a hexadecimal or decimal number by rotating a dial. This is incredibly useful for setting device IDs without needing 8 separate sliders.

- Learn more: Slide DIP vs Rotary DIP Switch Differences

- Piano DIP: Side-actuated levers that look like piano keys, often used on the edge of PCBs for better access.

Is there a cheaper alternative?

If your setting is truly permanent (never changes after the factory), you might not even need a DIP switch.

- Compare options here: DIP Switch vs Jumper Comparison

Deep Dive: When to Use a Toggle Switch

Toggle switches are the standard for power and function control. If your user is wearing safety gloves, or if the switch controls a motor, a DIP switch is physically too small and electrically too weak.

Current Handling

A standard DIP switch can melt if you run a motor directly through it. Toggle switches are built with robust internal contacts capable of handling AC mains voltage or high-current DC loads.

Panel Mounting vs. PCB Mounting

While DIP switches almost always live directly on the circuit board, toggle switches are frequently panel-mounted. This means the body sits inside the enclosure, but the lever sticks out for the user.

- For a broader look at industrial needs: Industrial Switch Comparisons

Integration and Environmental Factors

PCB Real Estate and Assembly

How you mount the switch affects your manufacturing costs. DIP switches are designed to fit standard integrated circuit footprints (2.54mm pitch), making them easy to machine-place.

- Read more on mounting: D-DIP Switch vs Through-Hole Mounting

Harsh Environments

If your device operates outdoors or in a wet factory, standard switches will fail due to corrosion.

- Toggle Switches: Often come with rubber "boots" or internal O-rings to achieve IP67 ratings.

- DIP Switches: Can be ordered with "tape seals" that protect them during the washing phase of PCB manufacturing, but the seal is usually removed for use.

- Related sealing guide: Sealed vs Waterproof Tact Switch (Principles apply to toggles as well).

Alternative User Interfaces

Sometimes, neither a toggle nor a DIP is the right fit.

- If you need a "momentary" signal (like a reset button), a Tactile Switch is superior.

- If you need precision position detection (like detecting if a door is closed), a Micro Switch is preferred.

- Detailed comparison: Tact Switch vs Micro Switch

Frequently Asked Questions

Technically yes, but it is not recommended. DIP switches are not designed for frequent toggling. They lack the physical durability for daily use and are difficult to operate quickly in an emergency.

The standard pitch is 2.54mm (0.100 inches), which matches the spacing of standard breadboards and IC sockets. "Half-pitch" (1.27mm) versions exist for high-density miniature electronics.

Because DIP switches often carry very low-voltage logic signals, even a tiny amount of oxidation can break the circuit. Gold plating ensures a reliable connection even after sitting idle for years.

Generally, no. Toggle switches usually have lower contact resistance because they have higher contact pressure and larger surface areas, allowing them to carry more current efficiently.

Key Takeaways

- Rule of Thumb: Use Toggle switches for people; use DIP switches for processors.

- Space: DIP switches offer the highest density of control points per square millimeter.

- Power: Never route high current through a DIP switch; use it only for logic signals.

- Cost: DIP switches are generally cheaper per pole, but Toggle switches last significantly longer in active use.

Conclusion

The decision between a DIP switch and a toggle switch rarely overlaps. If you are building the "brains" of the device where settings are fixed, the DIP switch is your compact, cost-effective solution. If you are building the "face" of the device where users interact daily, the Toggle switch provides the necessary durability and tactile feel.

Ready to specify your components?

- For complex configuration needs, explore our Rotary vs Slide DIP guide.

- For robust user interfaces, view our Industrial Switch Comparisons.