SMD DIP Switch vs Through-Hole DIP Switch: The Designer's Guide

Choosing between an smd dip switch vs through hole component is often the first real argument a junior engineer has with their production manager. I vividly remember my first PCB design review; I had specified a rugged through-hole switch because it "felt" sturdier. The manufacturing lead looked at the Bill of Materials, sighed, and asked if I planned to hand-solder all 5,000 units myself.

It was a harsh lesson, but a necessary one. The choice between Surface Mount Device (SMD) and Through-Hole Technology (THT) isn't just about how the switch attaches to the board—it dictates your manufacturing speed, board real estate, and long-term reliability.

In this guide, we are moving beyond the datasheet. We will explore the manufacturing realities, the mechanical stress factors, and the cost implications that determine which switch belongs on your board.

What is the Main Difference Between SMD and Through-Hole DIP Switches?

The primary difference lies in how they connect to the Printed Circuit Board (PCB). Through-Hole (THT) switches have long metal leads that pass through drilled holes in the board and are soldered on the opposite side. SMD (Surface Mount Device) switches sit flat on the board's surface, soldered directly to metal pads, allowing for automated assembly and higher component density.

The Technical Deep Dive

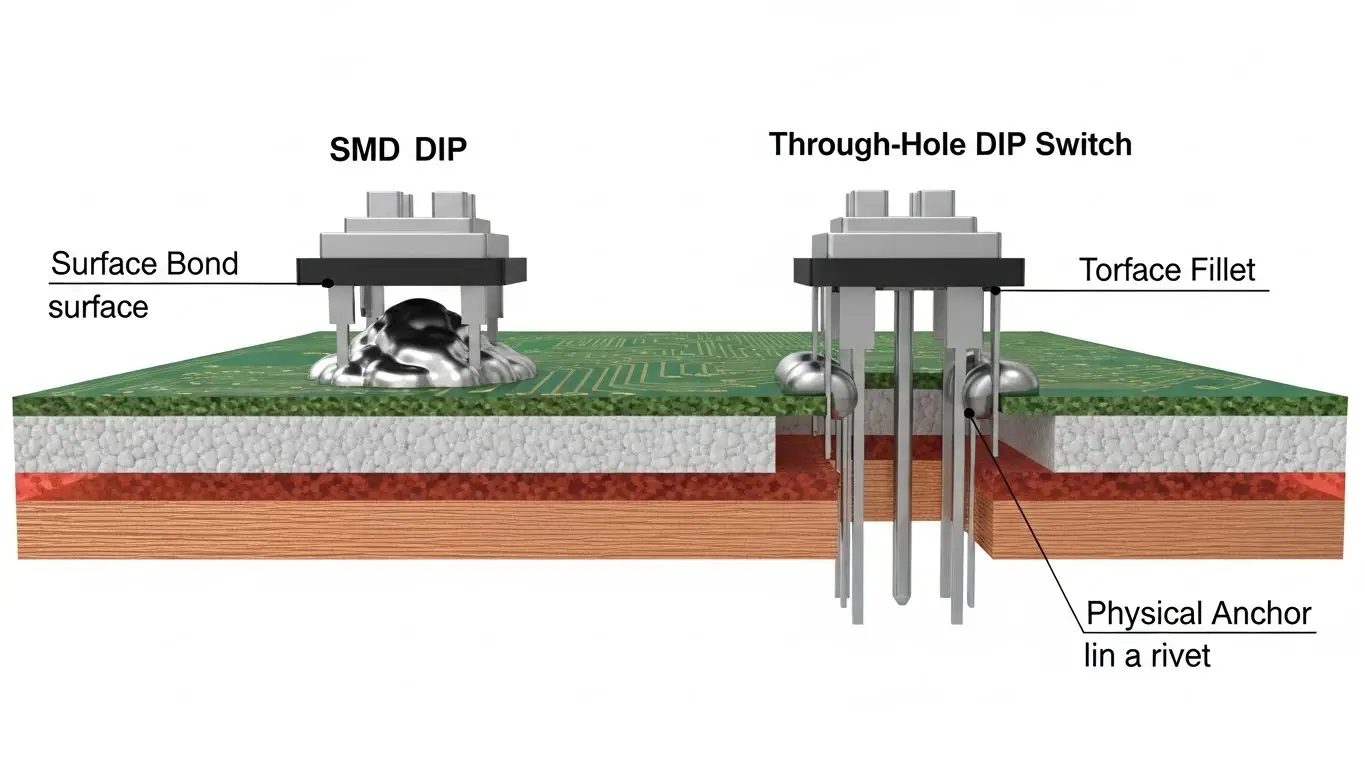

To understand the smd dip switch vs through hole debate, you have to look at the anatomy of the connection.

- Through-Hole Technology (THT):This is the "classic" style. The switch has legs (leads) that are inserted into plated holes.

- The Anchor: Because the leads go through the fiberglass substrate (FR4), the mechanical bond is incredibly strong. You are essentially riveting the component to the board.

- The Solder Joint: The solder fills the hole (the barrel) and forms a fillet on both the top and bottom.

- Best For: Prototypes, high-stress actuation, and hobbyist projects.

- Surface Mount Technology (SMT/SMD):These switches have small "gull-wing" or "J-lead" legs that rest on top of copper pads.

- The Process: Solder paste is stenciled onto the pads, the switch is placed by a robot, and the board travels through a reflow oven.

- The Space Saver: Because no holes are drilled, you can route tracks on the layer directly beneath the switch.

- Best For: Mass production, miniaturized devices, and complex multi-layer boards.

Engineer’s Note: While THT feels stronger, modern SMD switches often include "retention pegs" or ground pads to add mechanical stability without requiring a full through-hole process.

Which Switch Style is Better for Manufacturing Efficiency?

SMD is the undisputed king of manufacturing efficiency. For high-volume production runs (1,000+ units), SMD allows for fully automated "pick-and-place" assembly and reflow soldering. Through-hole components often require a separate "wave soldering" step or, worse, manual hand-insertion, which drastically increases labor costs and slows down the production line.

The "Pick-and-Place" Reality

If you are building industrial switch comparisons for a mass market, time is your most expensive resource.

- The SMD Workflow:

- A machine picks the switch from a tape-and-reel.

- It places it on the board in milliseconds.

- The board goes into an oven. Done.

- The Through-Hole Bottleneck:

- Standard pick-and-place machines cannot handle THT parts easily (though some expensive "insertion machines" exist).

- Usually, a human operator must insert the switch.

- The board then needs to go through a "wave solder" machine (a literal pool of molten solder).

- The Risk: If you have a board that is 99% SMD and you add one THT DIP switch, you have just forced the manufacturing house to set up a completely different soldering process for a single component.

Data Placeholder: [Insert graph showing the cost curve intersection between manual assembly vs. automated assembly at 500 units]

How Do Mechanical Strength and Durability Compare?

Through-hole switches offer superior mechanical strength. Because the leads pass entirely through the PCB, they can withstand significantly more downward pressure and lateral force during actuation. SMD switches rely solely on the solder pad's adhesion to the board surface; if a user presses too hard, there is a risk of ripping the copper pad right off the fiberglass.

The "Heavy Hand" Factor

DIP switches are unique because users physically interact with them. Unlike a capacitor that sits there passively, a DIP switch gets poked with screwdrivers, pens, and fingernails.

- The THT Advantage:I once worked on a project for heavy machinery controls. The technicians wore thick gloves and used heavy tools. We used THT switches because when a technician pushes a slider with 5lbs of force, the THT leads transfer that energy into the board structure.

- Result: The switch stays put.

- The SMD Risk (Pad Lifting):With an SMD switch, the only thing holding the switch to the board is the chemical bond between the copper foil and the epoxy resin of the PCB.

- Failure Mode: If the switch is stiff and the user forces it, the lever action can peel the copper pad up (delamination). Once a pad lifts, the trace breaks, and the board is dead.

Pro Tip: If you must use SMD in a high-vibration environment or for a device that will be configured frequently, look for SMD switches with mounting bosses. These are plastic pegs on the bottom of the switch that fit into non-plated holes for stability, giving you THT strength with SMD compatibility.

When Should You Use a Through-Hole DIP Switch?

Choose Through-Hole when prioritizing durability, repairability, or prototyping. They are ideal for harsh industrial environments where vibration is constant, or for educational kits and development boards where users might need to desolder and replace components. They are also the standard for legacy designs that utilize single-sided PCBs.

Specific Use Cases for THT

- Prototyping & Breadboarding:You cannot plug an SMD switch into a breadboard. THT is essential for the design phase.

- High-Vibration Zones:If the device is mounted on a vibrating motor or inside a vehicle, the solder joints of an SMD component can crack over time due to metal fatigue. THT leads have a slight flexibility that absorbs this stress better.

- Field Repairability:If a switch fails in the field, a technician with a basic soldering iron can easily replace a THT switch. Replacing a fine-pitch SMD switch requires hot air stations, tweezers, and a steady hand—luxuries not found in a van.

Reference: This mirrors the logic found in our DIP switch vs jumper comparison, where the choice often comes down to who is interacting with the hardware.

When is an SMD DIP Switch the Right Choice?

Choose SMD for high-density designs, automated manufacturing, and cost reduction. If you are designing a compact IoT device, a consumer gadget, or any double-sided PCB where space is at a premium, SMD is the mandatory choice. It allows for faster assembly times and frees up critical space on the underside of the board.

The "Real Estate" War

On a modern PCB, every millimeter costs money.

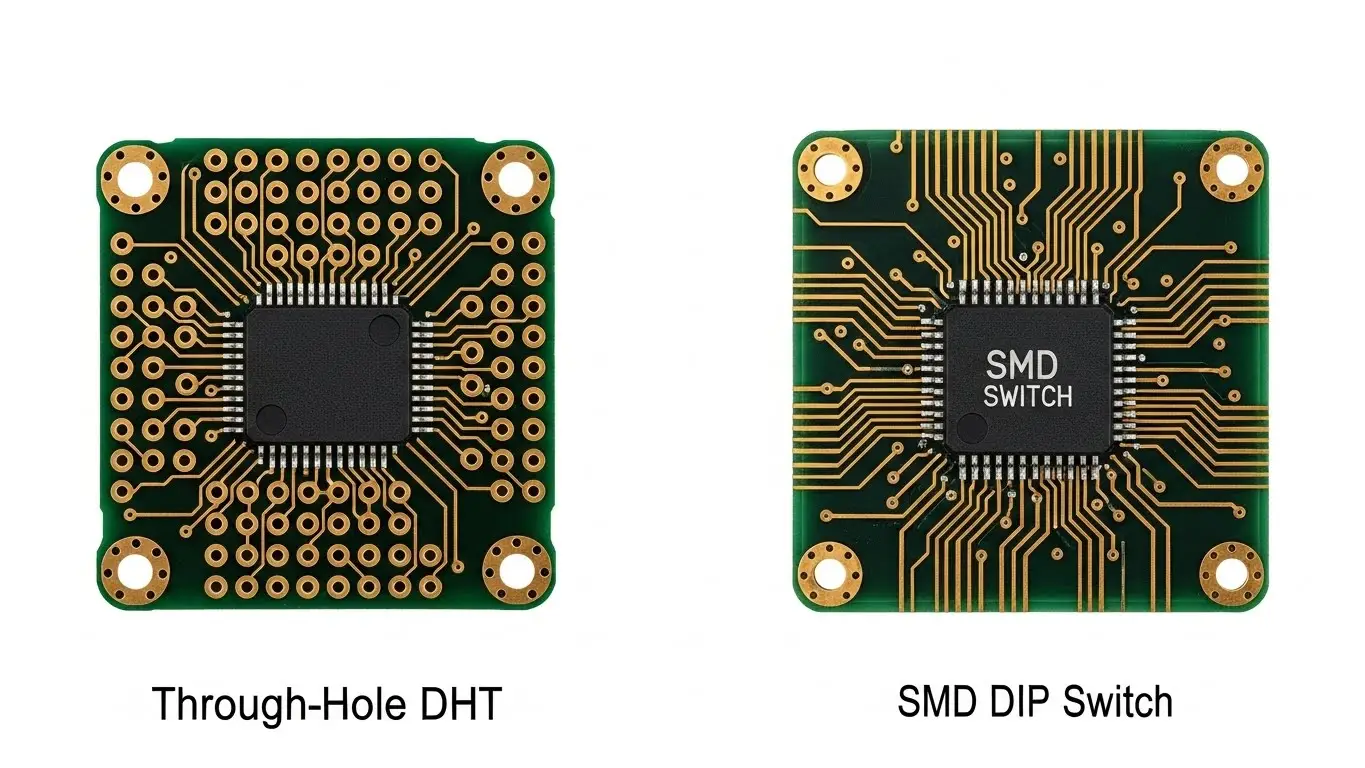

- No Drilling: Drilling holes is a slow part of PCB fabrication. Reducing hole count reduces board cost.

- Double-Sided Routing: With THT, the leads poke out the bottom, blocking you from running wires (traces) in that area on the bottom layer. With SMD, the bottom layer is completely open for complex routing or placing other components (like decoupling capacitors) directly underneath the switch on the opposite side.

- Profile Height: SMD switches are generally lower profile. If your device needs to fit inside a slim plastic enclosure (like a smart thermostat), the THT leads on the back might short out against the case or simply not fit.

Cost Analysis: Is SMT Cheaper than Through-Hole?

While the component price is similar, SMD is significantly cheaper at scale. The "Total Landed Cost" of an SMD switch is lower because it eliminates manual labor and secondary soldering steps. However, for small batches (<100 units), THT may be cheaper because it avoids the setup costs of stencils and pick-and-place programming.

Breaking Down the BOM (Bill of Materials)

Let’s look at the hidden costs:

| Cost Factor | Through-Hole (THT) | Surface Mount (SMD) |

| Unit Price | $0.50 | $0.52 (slightly higher for packaging) |

| PCB Fabrication | Higher (Drilling holes costs machine time) | Lower (Less drilling) |

| Assembly Setup | Low (Hand solder) | High (Stencil + Programming) |

| Assembly Labor | High (Manual insertion = slow) | Low (Robots = fast) |

| Inspection | Visual | AOI (Automated Optical Inspection) |

The Verdict: If you are making 10 units, buy THT. If you are making 10,000 units, buying THT is financial suicide.

How Does Soldering Heat Affect the Choice?

SMD switches must withstand higher temperatures than THT switches. Because SMD parts go through a reflow oven (often reaching 260°C for lead-free solder), they are made of high-temperature thermoplastics (like LCP or Nylon 6T). THT switches, often hand-soldered or wave-soldered, are exposed to heat for shorter durations or only on the leads, not the body.

The Melting Point Danger

This is a classic rookie mistake.

- Scenario: An engineer specifies a cheap standard DIP switch for an SMD board.

- The Event: The board goes into the reflow oven. The plastic housing of the switch warps, or the internal lubricant boils and coats the contacts.

- The Result: The switch is "open" (non-conductive) right out of the factory.

Checklist for SMD Selection:

- Ensure the datasheet specifies "Reflow Compatible."

- Look for tape seals. These removable seals prevent the flux (cleaning acid) and solder vapors from entering the switch body during the oven process. You peel the tape off after the board is washed.

Comparison Table: SMD vs Through-Hole DIP Switch

| Feature | Through-Hole (THT) | Surface Mount (SMD) |

| Assembly Method | Manual or Wave Solder | Pick-and-Place Reflow |

| PCB Space | Requires holes (blocks bottom layer) | Surface pads (bottom layer free) |

| Mechanical Strength | Excellent (Anchored through board) | Moderate (Dependent on pad adhesion) |

| Vibration Resistance | High | Medium (Susceptible to fatigue) |

| Cost (Low Volume) | Lower | Higher (Setup costs) |

| Cost (High Volume) | Higher (Labor intensive) | Lower (Automated) |

| Best For | Prototypes, Heavy Duty, Repair | Mass Production, Miniaturization |

FAQs: Selecting the Right DIP Switch

Yes, but it complicates assembly. You will have to solder that specific component by hand after the rest of the board has gone through the reflow oven. This is known as "secondary operation" and adds cost.

Standard DIP switches (both THT and SMD) usually have a 2.54mm (0.1 inch) pitch. However, SMD switches are increasingly available in 1.27mm (0.05 inch) "half-pitch" versions. These are incredibly small and save massive amounts of space, but they are harder to actuate without a tool.

They are robust enough for configuration settings (set once, rarely touched). If you expect the user to toggle the switch daily, you should probably not use a DIP switch at all, but rather a panel-mount toggle switch or a button.

This is usually a design error or a user error.

Design: The copper pads on the PCB were too small.

User: Too much force was used with a sharp tool.

Solution: Increase the pad size in your EDA software (Altium/Eagle/KiCad) to provide more surface area for the glue to hold.

Conclusion

The battle of smd dip switch vs through hole is not a question of "better," but of "fit."

If you are designing the next generation of smart home sensors, the SMD DIP switch is your only logical path—it’s sleek, automatable, and compact. However, if you are building a rugged controller for a hydraulic press or a DIY kit for students, the Through-Hole DIP switch remains the champion of reliability and ease of use.

Before you finalize your Bill of Materials, imagine the lifecycle of the product: How is it made? Who touches it? How often? Answer those three questions, and the switch will practically select itself.