What Makes a Reliable Custom Micro Switch Manufacturer in China Stand Out

A Custom Micro Switch Manufacturer can promise low cost and fast delivery. But will the actuation feel stay consistent? Will contacts stay clean under heat, dust, and vibration? Will samples match mass production? You need evidence, not slogans. Data, not guesswork. Behind every "click" is a chain of materials, automation, and testing. One weak link can stall a line or trigger a recall. So what separates a true partner from a risky bet? When teams source critical components, they want steady quality, honest timelines, and help when the unexpected happens. As Hanxia, a leading switch producer in China since 2014, we've heard the stories: parts that feel different across batches, signal bounce that disturbs control logic, and long waits when a line is down. Reliability is not a slogan. It is a system - materials, methods, measurement, and service - working together day after day.

The Reliability System: From Materials To Measurements

Reliability starts long before a part meets a PCB. We select high-grade raw materials and control them from incoming inspection to final pack-out. Fully automated assembly removes human variability, and automated inspection checks the details you can't see with the naked eye - actuation force curves, contact resistance, and repeatability over cycles. Functional testing validates that each unit behaves as designed before it leaves the line.

Those controls reduce the most common pain points buyers report with a Custom Micro Switch Manufacturer in China: uneven actuation feel, early wear on moving parts, contact chatter under vibration, and missed ship dates. Ask any supplier two simple questions: How many manual steps remain in your line? and What statistical evidence can you share for force, travel, and life? Real reliability leaves a trail of numbers.

✅ What you can verify with Hanxia

• Automated assembly and automated inspection minimize variation.

• Functional test data captured against actuation and contact metrics.

• Lifecycle targets engineered for millions of operations under load.

Scale You Can Plan Around

A stable line means a stable roadmap. Our factory spans 5,600 m², staffed by 90+ skilled technicians and powered by 38 fully automated production lines. By 2025, we've served 3,625 enterprises, including many listed companies that audit both process and results. Daily capacity exceeds 2 million units, with regular goods shipping in 2 - 6 working days. That mix - volume with speed - helps OEMs move from pilot to mass production without scrambling for a second source.

Compliance and documentation matter, especially for export programs. Hanxia holds CE, REACH, RoHS 2.0, and ISO 9001 certifications, alongside utility patents. Technical exchanges with leading Korean counterparts keep our tolerances tight and our designs current, so when your spec changes, we can respond quickly rather than retool from scratch.

✅ What this means for your program?

• Short, predictable lead times for standard configurations.

• Fast DFM feedback to de-risk new designs.

• Clear compliance files for regulatory submissions and audits.

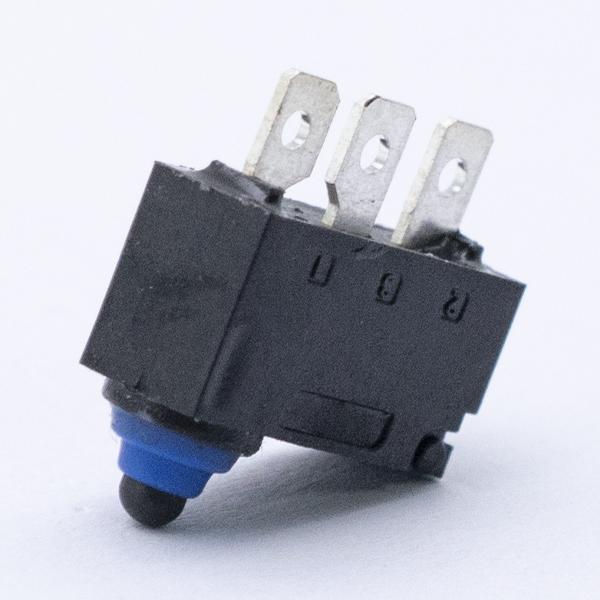

What A Micro Switch Must Do - Every Time

A micro switch is a small, sensitive device that changes state with very little force. In practice, that means it must trigger precisely, resist arcing, and keep a stable signal - whether it sits in an appliance door, a limit station on a conveyor, a seat-belt buckle, or a medical device latch. Failure looks different in each setting: a production line pause, a user complaint about "stickiness," a false alarm in a safety system. The root causes are often the same - poor contact geometry, inconsistent springs, or contamination during assembly.

Hanxia's approach addresses those risks:

• Precision Actuation: Force and travel are tuned to narrow bands, delivering a consistent "click" and predictable switching.

• Stable Electrical Contact: Clean, repeatable closures limit bounce and noise in control circuits.

• Compact Integration: Small footprints fit tight housings without redesigns downstream.

• Environmental Range: Designs operate across temperature and humidity swings common in field use.

• Long Service Life: Components are specified and validated for endurance over millions of cycles.

Design Choices That Lower Your Total Cost

Real savings appear when a part installs without fuss, runs without drift, and passes audits the first time. That's why we focus on options that avoid rework:

• Actuator Forms: Levers, rollers, and push-buttons match the motion profile of your mechanism.

• Mounting Flexibility: Hole patterns and terminals suit common assembly methods and wiring preferences.

• Contact Options: Configurations that balance current needs with longevity and safety margins.

For new projects, our engineers recommend a quick, focused DFM session - stroke, force, environment, and duty cycle - followed by a pilot run from the same automated lines that will make your mass production. That keeps your test data representative and your schedule realistic.

✅ Service That Doesn't Disappear After Delivery

A dependable Custom Micro Switch Manufacturer China supports the full lifecycle. Hanxia's standard goods carry a 90-day no-reason return policy. More important for complex builds, our engineering team provides on-site solutions when needed. If a switch lives inside a tight assembly or faces dust, vibration, or fluids, root-cause analysis works best on the ground: measure, simulate, adjust, and lock the fix.

When you compare suppliers, look for three signals:

• Process Control: How automated is the line, and what SPC data is shared?

• Measured Reliability: Cycle life, return rates, and third-party certifications.

• Service Depth: Sample speed, FA reports, and willingness to troubleshoot at your site.

Why Hanxia Often Becomes The Second Source - And Then The First

Many customers first contacted us to dual-source a critical SKU. They stayed because parts from different lots felt the same, because shipments arrived when promised, and because our team answered with data, not guesswork. That is how a Custom Micro Switch Manufacturer in China earns trust - by turning every order into proof.

• Founded 2014; serving 3,625+ enterprises by 2025.

• 2M+ units/day capacity; 2 - 6 working days for regular goods.

• CE, REACH, RoHS 2.0, ISO 9001, utility patents.

• Technical exchanges with top Korean partners.

Call To Action: Bring Us Your Constraints

If you're qualifying a Custom Micro Switch Manufacturer China for a new platform or replacing a fragile part, bring us your constraints - available space, target force, environment, and life. Ask for a rapid DFM review and a pilot lot from production tooling. We'll return a concrete plan, testable samples, and a shipping schedule you can anchor to.

Build With Confidence. Build With Hanxia.

Let our engineers translate requirements into reliable, certifiable, and scalable production. When the switch simply works - batch after batch - everything upstream and downstream moves faster.