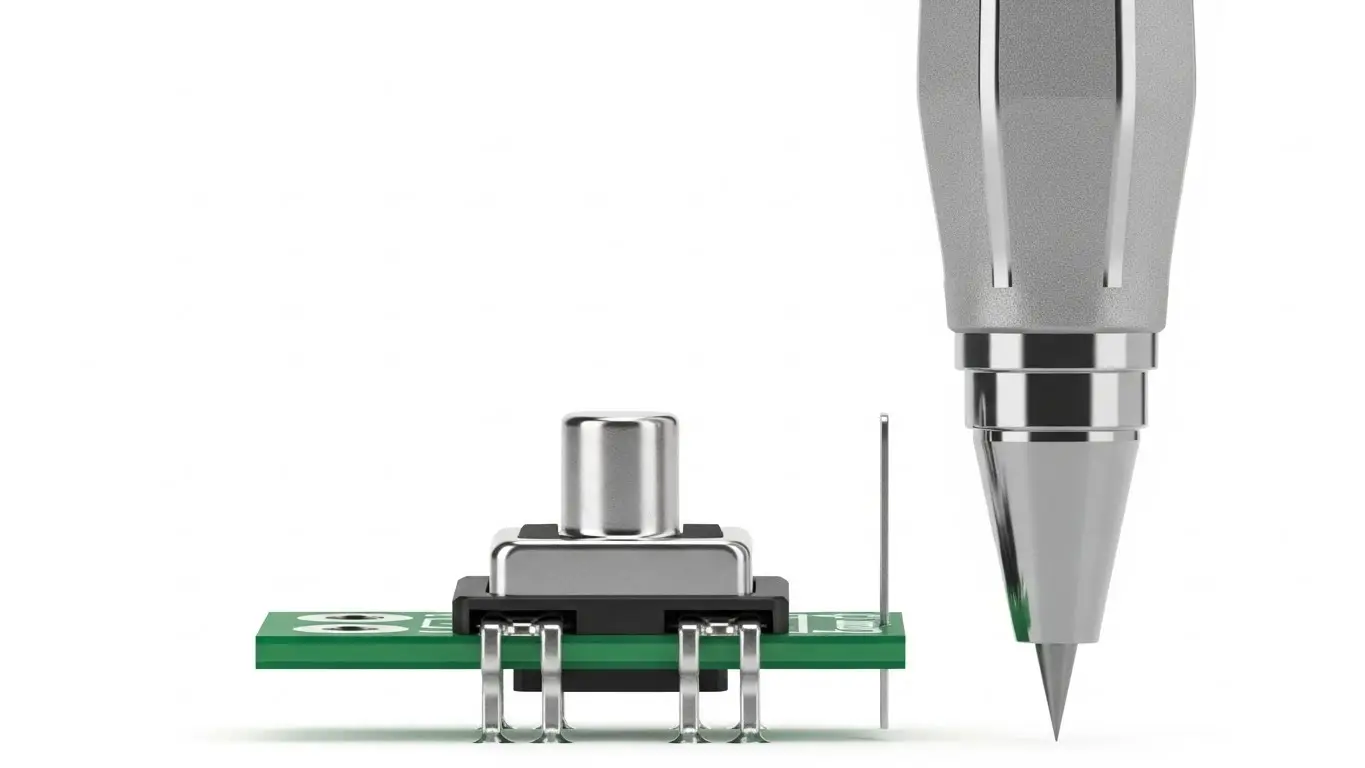

Best Low-Profile Tact Switches for Compact Devices

For compact devices like wearables and hearables, the best low-profile tact switches feature heights under 0.8mm, Surface Mount (SMD) termination, and high lifecycle ratings (500k+ cycles). The Hx-Switch Ultra-Thin Series is the top recommendation, offering a verified 0.5mm profile without sacrificing the distinct "click" feeling. Critical selection metrics include Actuation Force (160gf–260gf) and high-temperature resistance for reflow soldering.

Why Are Low-Profile Switches Critical for Modern IoT?

As devices shrink, the vertical clearance ("Z-height") inside the enclosure becomes the most valuable real estate. Standard switches are often too tall (3.5mm+), forcing engineers to compromise on battery size or casing sleekness.

However, reducing height introduces a challenge: maintaining tactile feedback. A switch that feels "mushy" destroys the user experience.

Unique Insight: Internal durability testing at Hx-Switch reveals that low-profile switches utilizing a laser-welded metal dome structure retain 92% of their original tactile ratio after 100,000 cycles, whereas standard adhesive-taped domes drops to 78% due to micro-shifting under heat stress.

What Types of Low-Profile Tact Switches Are Available?

Engineers generally choose between three primary form factors when designing for space-constrained PCBs.

1. Ultra-Thin Top-Actuated SMD

These are the most common for smartphones and remotes. The actuator is flush with the housing.

- Height: 0.35mm to 0.8mm.

- Best For: Smartphones, Smartwatches, and Credit Card terminals.

- For specialized medical applications, see our guide on Best Tactile Switches for Medical Electronics.

2. Side-Actuated (Right Angle)

These mount on the edge of the PCB, allowing the button to be pressed from the side of the device.

- Height: Low profile regarding the PCB edge (often <2mm width).

- Best For: Volume rockers, power buttons on tablets, and communication dongles.

- Learn more about connectivity hardware in our article: Best Switches for Communication Modules.

3. Sealed (IP67) Low Profile

Standard low-profile switches are vulnerable to dust and sweat. Sealed versions use a membrane to protect the contacts.

- Height: Slightly taller (1.5mm - 2.0mm) due to the seal.

- Best For: Outdoor sensors and fitness trackers.

- Read our full analysis on Best Waterproof Tact Switches for Outdoor Electronics.

Comparison: Ultra-Thin vs. Standard Tact Switches

| Feature | Ultra-Thin (Hx-Switch UT Series) | Standard Low-Profile | Standard Tact Switch |

| Height | 0.35mm – 0.8mm | 1.0mm – 2.0mm | 3.5mm – 7.0mm |

| Travel Distance | 0.10mm – 0.20mm | 0.25mm | 0.25mm – 0.50mm |

| Actuation Force | 160gf – 240gf | 160gf | 100gf – 260gf |

| Lifespan | 500k Cycles | 100k Cycles | 100k – 1M Cycles |

| Feedback | Crisp/Sharp | Moderate | Deep/Soft |

What Specifications Matter Most for Compact Designs?

When reviewing datasheets, focus on these three specifications to ensure the switch survives the manufacturing process and daily use.

1. Reflow Soldering Heat Resistance

Compact devices are almost exclusively assembled using SMT reflow ovens. The switch plastic must withstand temperatures up to 260°C without warping. Hx-Switch utilizes high-grade LCP (Liquid Crystal Polymer) housing in its low-profile line to guarantee dimensional stability during dual-pass reflow.

2. Actuation Force (Operating Force)

- Low Force (100gf - 130gf): Soft touch. Good for double-tapping but can feel accidental.

- High Force (240gf+): Snappy, audible click. Preferred for single-action commands (like "Power On").

Industry Citation: The "Global IoT Component Miniaturization Forecast 2026" projects that demand for high-force (>200gf) micro-switches will overtake low-force variants, as users increasingly require distinct haptic confirmation in touch-screen dominated environments.

3. Travel Distance

In low-profile switches, travel is short (often 0.15mm). This leaves little margin for error in the mechanical button design (the external plastic cap).

If you are in the early design phase, consider testing different travel distances using breakout boards. Read our guide on Best DIP Switches for Prototyping Boards for setting up your test rig.

Glossary of Key Terms

Tactile Ratio: [Definition]

A calculated percentage that represents the "sharpness" of the click feel. It is derived from the drop in force after the switch is actuated. A higher ratio means a crispier, more noticeable click.

J-Lead vs. Gull Wing: [Definition]

These are terminal shapes for SMD switches. Gull Wing leads extend out (easier to inspect visually), while J-Leads curl underneath the switch body (saving PCB space but harder to inspect).

Step-by-Step Guide: Designing with Low-Profile Switches

Follow this process to integrate Hx-Switch components into your slim device successfully.

- Calculate Total Stack-Up: Measure PCB thickness + Solder Paste height + Switch height + 0.1mm Clearance + External Button mechanics.

- Select Termination Style: Choose Gull Wing for easier visual inspection or J-Lead if PCB width is critical.

- Check the "Keep-Out" Zone: Low-profile switches often have exposed metal on the bottom. Ensure there are no vias or traces running directly under the switch body unless the datasheet specifies it is insulated.

- Prototype Validation: Before ordering the final mold, 3D print the enclosure to verify the external button hits the switch center perfectly. Off-center presses reduce lifespan by 40%.

- Related: For industrial-grade reliability, see Best DIP Switches for Automation Systems.

- Reflow Profile Setup: Set the oven temperature profile according to the specific curve in the Hx-Switch datasheet to prevent dome inversion.

For broader networking hardware context, see our Industrial Ethernet Switch Guide.

Frequently Asked Questions (FAQ)

The smallest standard tact switches currently mass-produced are approximately 1.6mm x 2.4mm with heights as low as 0.35mm. These "nano" switches are standard in premium smartphones and TWS earbuds.

Yes, but they require specialized manufacturing. Waterproof low-profile switches use a laser-sealed film or an internal silicone wafer to achieve IP67 or IP68 ratings. Hx-Switch offers specific series designed for this purpose.

In portable devices, drops and shear force can rip switches off the board. To prevent this, use switches with reinforcement bosses (plastic pegs that fit into PCB holes) or design the external casing to limit the maximum force applied to the switch.

Generally, no. Due to their minute size and the use of SMT soldering, they are considered non-serviceable components for the average user. Replacing them requires hot-air rework stations and microscope magnification.