Best DIP Switches for Industrial Control Panels: The Engineer’s Guide to Reliability

Selecting the best DIP switches for industrial control panels is rarely the highlight of a design review, but it is often the single component that dictates long-term configuration reliability. In my years troubleshooting factory automation floors, I have seen entire production lines halted not by a failed PLC, but by a cheap, corroded DIP switch that lost its address setting. When vibration, dust, and temperature fluctuations are the norm, standard commercial components simply do not survive.

This guide provides a definitive engineering breakdown of selecting, implementing, and protecting DIP switches within industrial environments.

Why Are DIP Switches Critical for Industrial Control Panels?

DIP switches provide a hardware-level, non-volatile method for setting device addresses, baud rates, and termination resistance in industrial panels. Unlike software settings, which can be wiped by firmware updates or power surges, a physical DIP switch retains its state permanently. They offer immediate visual verification of settings for maintenance technicians without requiring a laptop connection.

The "Set and Forget" Philosophy

In the world of industrial automation—whether we are talking about VFDs (Variable Frequency Drives), HMI panels, or DIN-rail mounted isolators—the philosophy is "set and forget."

However, "forget" is dangerous if the component degrades. I once serviced a remote telemetry unit in a water treatment plant where the DIP switch contacts had oxidized. The unit "forgot" its Modbus ID. The result? A communication timeout that triggered a false alarm for a tank overflow.

Reliability in these panels hinges on three things:

- Vibration Resistance: Can the actuator stay in the "ON" position when a 500hp motor kicks on nearby?

- Contact Integrity: Will the signal remain pure after 10 years in a humid cabinet?

- Accidental Actuation: Is it easy for a stray cable to flip a switch?

For engineers designing the communication backbones of these systems, understanding the network hardware is just as vital as the switch itself. You can explore how these components interact in our Industrial Ethernet Switch Guide.

What Types of DIP Switches Work Best in Harsh Environments?

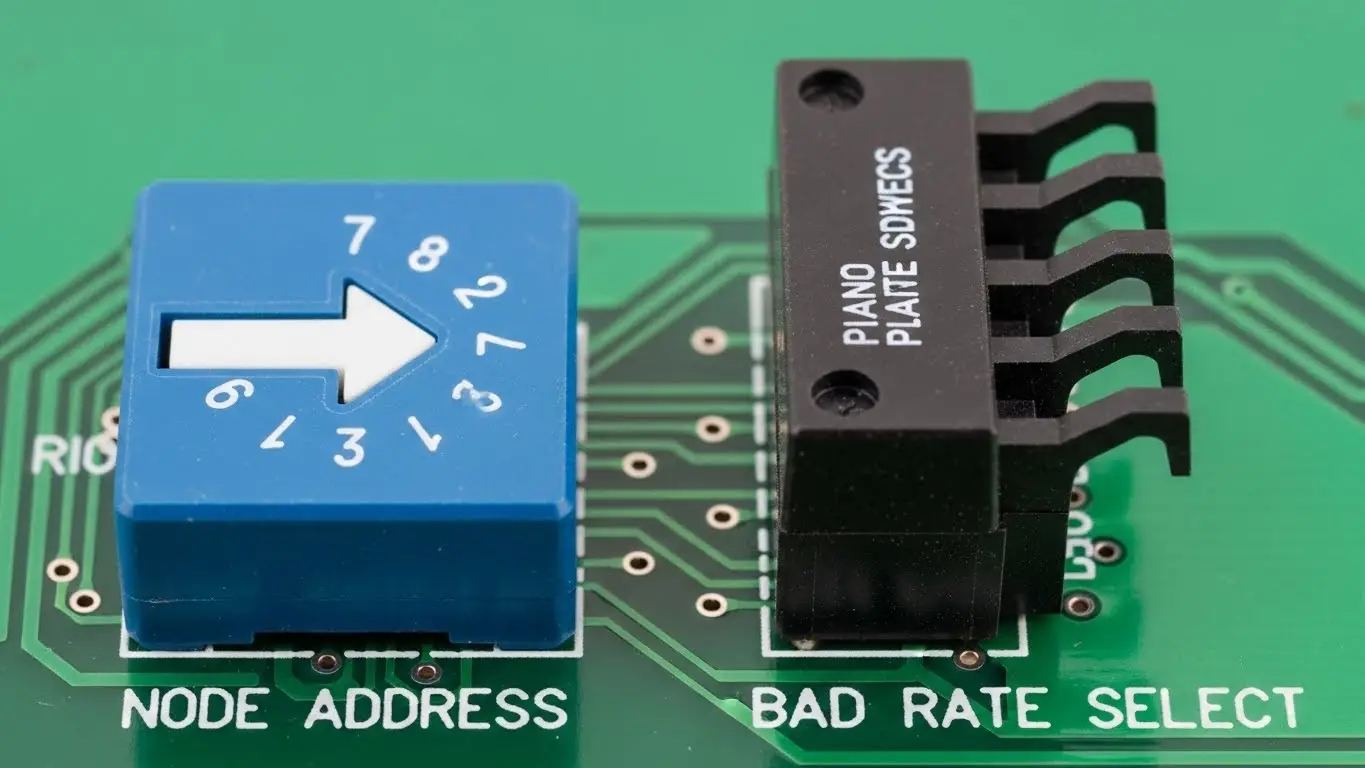

Rotary DIP switches and Piano-style (side-actuated) DIP switches are superior for industrial environments due to their ease of access and robust sealing options. Rotary switches are particularly favored for setting device IDs as they prevent invalid binary combinations, while recessed slide switches offer better protection against accidental actuation during panel maintenance.

Rotary DIP Switches: The Industrial Favorite

If you are designing a device that needs a specific node address (0-9 or 0-F), use a rotary DIP switch.

- Space Efficient: One component replaces 4 distinct slide switches.

- Error Proofing: It is impossible to set an ambiguous state (like "all off" when a value is required).

- Tooling: Technicians can adjust them with a standard flathead screwdriver, which is always in their pocket.

Piano vs. Slide Actuators

- Slide (Top Actuated): Standard, but can be hard to reach if PCBs are stacked vertically.

- Piano (Side Actuated): Ideal for edge-of-board placement. If your control panel uses DIN-rail modules packed tightly together, piano switches allow technicians to change settings without disassembling the rack.

If you are prototyping a new controller board, you might initially use standard open-frame switches. However, moving to production requires a different mindset. See the transition from lab to floor in our guide on Best DIP Switches for Prototyping Boards.

How Does Contact Material Affect Long-Term Reliability?

Gold-plated contacts are mandatory for industrial control panels because DIP switches typically operate at "logic level" voltages and currents (low energy), where there is insufficient power to arc through oxide layers. While silver is conductive, it tarnishes quickly in sulfur-rich industrial air, leading to open circuits. Gold resists corrosion, ensuring the signal reads "TRUE" even after years of inactivity.

The Wetting Current Problem

This is the most common failure mode I see. A DIP switch connects a 3.3V GPIO pin to Ground. The current flow is practically zero.

- Silver Contacts: Over time, silver sulfide forms. Since the switch isn't being toggled (no wiping action) and the current is too low to punch through the tarnish, the circuit eventually reads as "Open" even when the switch is closed.

- Gold Flash/Solid Gold: Gold is inert. It does not react with sulfur or oxygen.

For industrial panels located in wastewater plants, paper mills, or chemical processing facilities, gold is not a luxury; it is a requirement. This mirrors the strict standards found in healthcare technology, where signal failure is not an option. You can read about similar high-reliability requirements in our article on Best Tactile Switches for Medical Electronics.

Do You Need Sealed DIP Switches for NEMA/IP Rated Panels?

Yes, sealed DIP switches are recommended even inside NEMA/IP rated panels to protect against "micro-environments" caused by condensation and outgassing from other components. Tape seals protect the switch during the soldering/washing process, while full IP67 epoxy seals prevent fine dust and moisture ingress during the decades-long service life of the equipment.

The Tape vs. Epoxy Debate

- Top Tape Seal: This is a thin film covering the actuators. Its primary job is to survive the wave soldering bath and board washing. Warning: Technicians must peel this off to set the switch. Once peeled, the protection is gone.

- Bottom Epoxy Seal: This seals the gap between the plastic housing and the metal pins. It prevents "flux wicking" during manufacturing, which can glue the switch internals shut.

If your control panel is outdoors, condensation is inevitable when temperatures drop at night. Even if the enclosure is waterproof, the air inside holds moisture. For maximum protection, consider how other outdoor electronics handle this issue, as detailed in Best Waterproof Tact Switches for Outdoor Electronics.

How Should DIP Switches Be Arranged for Usability?

DIP switches should be placed near the board edge or behind a dedicated access door to minimize the risk of technicians touching high-voltage components during configuration. Clearly label the "ON" position and the function of each pole directly on the PCB silkscreen to prevent configuration errors in dimly lit industrial cabinets.

The Human Factor in Panel Design

I have opened panels where the DIP switches were located underneath a ribbon cable, next to a 480V transformer. This is bad engineering.

- Accessibility: Can a technician wearing gloves reach it?

- Visibility: Is the text legible? Use high-contrast silk screen (White text on Green/Black board).

- Protection: If the switch is flush with the board, consider a "recessed" actuator type. This requires a tool to move, preventing a stray wire from flipping the bit.

If space is at an absolute premium, such as in compact IoT sensor nodes or handheld diagnostic tools, you may need to look at lower-profile options. We discuss space-saving techniques in Best Low Profile Tact Switches for Compact Devices.

Comparison of Top Industrial DIP Switch Features

When specifying a switch for a Bill of Materials (BOM), use this matrix to select the right feature set.

| Feature | Standard Commercial | Industrial Grade | Best Application |

| Contact Plating | Silver / Tin | Gold (Flash or 30µ") | Logic level signals, Corrosive air |

| Actuator Type | Raised Slide | Recessed / Rotary | Anti-tamper, Address setting |

| Sealing | None | Top Tape + Bottom Epoxy | Washable assembly, Dusty zones |

| Operating Temp | -20°C to +70°C | -40°C to +85°C (or +105°C) | Outdoor cabinets, Motor enclosures |

| Pitch | 2.54mm | 1.27mm (Half Pitch) | High-density DAQ modules |

Export to Sheets

Pro Tip: For high-vibration environments (trains, heavy stamping presses), look for "high contact pressure" variants (often >500gf actuation force). These are harder to move but virtually immune to contact bounce caused by mechanical shock.

Troubleshooting and Maintenance of Industrial DIP Switches

Common DIP switch failures in control panels manifest as intermittent communication errors or incorrect device addressing. To troubleshoot, cycle the switch back and forth several times to "wipe" away contact oxidation. If using a multimeter, measure resistance across the closed switch; anything over 100 milliohms indicates potential degradation requiring replacement.

The "Self-Cleaning" Myth

Many engineers believe switches clean themselves. While the sliding action does scrape away some oxide, it cannot remove heavy corrosion.

- Do not use contact cleaner spray indiscriminately. Some solvents can dissolve the plastics used in DIP switches or wash lubricants away.

- Visual Inspection: Look for "contact walking" where vibration has caused the slide to move halfway between positions.

Sometimes, the issue isn't the fixed panel, but the tool used to test it. Handheld meters often have their own switch issues. For a broader perspective on mobile equipment switches, see Best Switches for Handheld Consumer Devices.

Conclusion: Specifying for the Long Haul

The best DIP switches for industrial control panels are the ones you never have to think about after installation. They resist the urge to corrode, they ignore the vibration of the factory floor, and they tell the controller exactly what it needs to know, year after year.

When creating your next schematic, spend the extra few cents for gold plating and epoxy seals. It is the cheapest insurance policy you will ever buy for your control system.

Frequently Asked Questions (FAQ)

A slide DIP switch has individual actuators for each bit (on/off), ideal for toggle settings. A rotary DIP switch uses a dial to select a specific value (0-9 or 0-F), making it perfect for setting device addresses without binary calculation errors.

Industrial panels often have corrosive atmospheres (sulfur, moisture). Gold plating prevents oxidation. Since DIP switches often sit for years without moving, and carry very low current, gold is the only material that guarantees a connection when the switch is finally needed.

Yes. Piano (side-actuated) switches are excellent for DIN-rail modules or crowded PCBs. They allow technicians to access the settings from the edge of the board without needing to reach over other live components or disassemble the stack.

While the panel is waterproof, the air inside still contains moisture which can condense. Using epoxy-sealed bases prevents flux from entering during manufacturing, and tape seals (or IP67 ratings) protect against dust and internal condensation over time.

Use recessed actuators (which require a tool to move) rather than raised actuators. Additionally, verify the switch is rated for high shock/vibration (MIL-STD-202) and consider using "stiff" detents that require higher force to actuate.