Best DIP Switches for Automation Systems

Best DIP switches for automation systems must balance reliability, environmental sealing, and ease of configuration. In industrial environments, the ideal choice is often a Rotary DIP switch for quick address setting or a Piano-style switch for side-access configuration. Prioritize gold-plated contacts for low-voltage logic circuits to prevent oxidation and ensure consistent signaling over decades of service.

In my 20 years of troubleshooting factory control panels, I have learned that a $0.50 DIP switch is often the "ghost" in the machine. I once spent six hours debugging a conveyor system only to find that a single slide switch had vibrated into an undefined state between "ON" and "OFF." Let’s break down how to select the right components to ensure your automation infrastructure remains bulletproof.

What Are the Best DIP Switch Types for Industrial Automation?

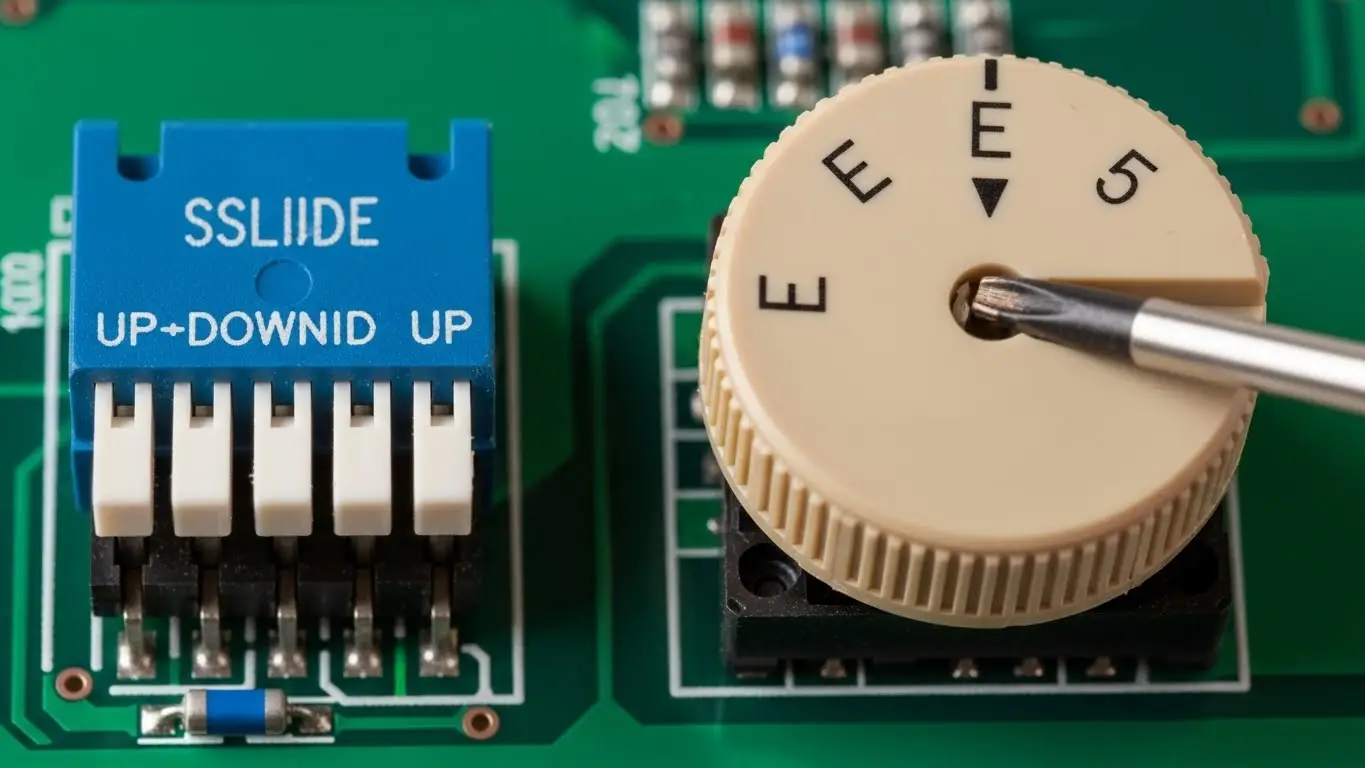

The best DIP switch types for industrial automation are Slide, Piano, and Rotary switches, each serving a specific interface role. Slide switches are the industry standard for "set-and-forget" configurations, Piano switches offer superior accessibility on edge-mounted PCBs, and Rotary switches are the premium choice for setting device addresses (0-9 or 0-F) without binary math.

Matching the Form Factor to the Function

In automation, form follows function. You aren't just picking a switch; you are designing a maintenance procedure.

- Slide DIP Switches: These are the workhorses. They are flat, robust, and usually protected by a recessed actuator to prevent accidental switching. Use these for permanent settings like baud rate selection on a gateway.

- Piano (Side-Actuated) DIP Switches: These are essential when the PCB is mounted vertically inside a DIN-rail enclosure. If a technician can't reach the switch without disassembling the unit, the design has failed.

- Rotary DIP Switches: These are the "Cadillac" of configuration. Instead of flipping four separate switches to set binary "1010," you simply turn a dial to "A." This reduces human error significantly during field installation.

For a broader look at how these components fit into larger industrial networks, reliable switching is just one part of the puzzle. You can explore our Industrial Ethernet Switch Guide to see how data moves from these physical settings to the network layer.

Why Do Contact Materials Matter: Gold vs. Silver?

Gold contacts are mandatory for low-voltage (logic level) applications common in automation to prevent signal loss due to oxidation. Silver contacts are cheaper and better for high-current switching, but in a 3.3V or 5V logic circuit, the silver sulfide tarnish that forms over time can create enough resistance to cause an "Open" reading even when the switch is closed.

The "Dry Circuit" Phenomenon

Automation controllers often run on "dry circuits"—where the voltage and current are too low to arc across the contacts and burn off contaminants.

- Gold (Au): Chemically inert. It does not rust or tarnish. If your PLC reads a digital input at 5V/1mA, you must use gold.

- Silver (Ag): Great for power, bad for logic. In a humid factory, a silver contact can fail within a year if not "wetted" by a higher current arc.

I’ve seen technicians try to save pennies by specifying silver contacts for IoT sensors, only to face massive recall costs later. For low-power devices, check our guide on Best Tact Switches for IoT Devices to understand why contact material is a non-negotiable spec.

How Important Is Ingress Protection (IP) in Factories?

Ingress Protection (IP) is critical; look for IP67-rated or "tape-sealed" switches if the PCB will undergo washing or operate in dusty environments. Standard unsealed switches are vulnerable to "flux wicking" during soldering and dust contamination during operation, which can insulate the internal contacts and cause intermittent signal failures.

Tape Seal vs. Full Seal

- Tape Seal: A temporary yellow or orange tape on top of the switch. This is designed only to survive the wave soldering and washing process during manufacturing. You peel it off after assembly.

- IP67 / Process Sealed: These switches have internal O-rings and sealed bases. They can survive being sprayed with water or coated in oil mist.

Pro Tip: If your automation cabinet is near a CNC machine (coolant mist) or a paper mill (conductive dust), spend the extra money for a fully sealed IP67 Rotary or Slide switch.

Rotary vs. Slide: Which Is Better for Address Setting?

Rotary DIP switches are superior for address setting because they eliminate binary calculation errors and offer better vibration resistance. While Slide switches are cheaper, setting a Node ID of "14" requires knowing the binary sequence (01110), whereas a Rotary switch simply points to "E," making it faster and safer for field technicians to configure.

The Human Factor in Automation

In the field, ease of use equals reliability.

- Slide Switch Risk: If a technician pushes a slide switch with a screwdriver, they might damage the actuator or leave it "floating" in the middle.

- Rotary Switch Benefit: They have a positive "detent" (click) that locks the position. This mechanical feedback is superior for vibration resistance.

Comparison Table: Rotary vs. Slide

| Feature | Slide DIP Switch | Rotary DIP Switch |

| Cost | Low ($0.20 - $0.50) | High ($1.50 - $3.00) |

| Setting Method | Binary (On/Off) | Hex/Decimal Dial |

| Space Efficiency | Low (8 pins for 8 bits) | High (4 pins for 16 codes) |

| Human Error | High (Requires binary math) | Low (Read directly) |

How to Troubleshoot Common DIP Switch Failures?

To troubleshoot failures, first verify the mechanical "click" of the actuator, then use a multimeter to check for high resistance caused by oxidation. Common failures include contact bounce from vibration, flux contamination insulating the contacts, and metal fatigue where the internal spring loses tension and fails to close the circuit.

The "Wiggle" Test

If an automation system is behaving erratically—like a servo motor resetting its ID randomly—go to the DIP switch.

- Power Down: Never change settings on a live system (hot switching).

- Exercise the Switch: Flip it back and forth 5-10 times. This "wiping action" can scrape off thin layers of oxide on silver contacts.

- Check Continuity: If resistance is >1 Ohm when closed, replace the switch.

Many "software bugs" are actually just dirty switches. Regular cycling of switches during maintenance intervals (if safe to do so) can extend their life significantly.

Frequently Asked Questions (FAQ)

Top-tier brands known for industrial reliability include Grayhill, TE Connectivity (Alcoswitch), Omron, and C&K. These manufacturers offer specific "industrial grade" lines with gold contacts and high-temperature housing materials.

Standard slide switches can suffer from "contact chatter" under heavy vibration. For high-vibration environments (like heavy machinery), Rotary DIP switches are preferred because their internal detent mechanism holds the position more securely than a sliding contact.

They are the same. Standard industrial DIP switches have a 2.54mm (0.100") pitch, which matches standard breadboards and IC sockets. "Half-pitch" (1.27mm) switches exist for high-density PCBs but are harder to adjust by hand.

In high-reliability automation, solder them directly. Sockets introduce another point of failure (corrosion between switch and socket). Only use sockets during prototyping.

Use a specialized Contact Cleaner spray (like DeoxIT). Do not use standard solvents or WD-40, which can leave a residue or dissolve the plastic housing. Spray sparingly and cycle the switch to clean the contacts.