Best Alternatives to Micro Tact Switches

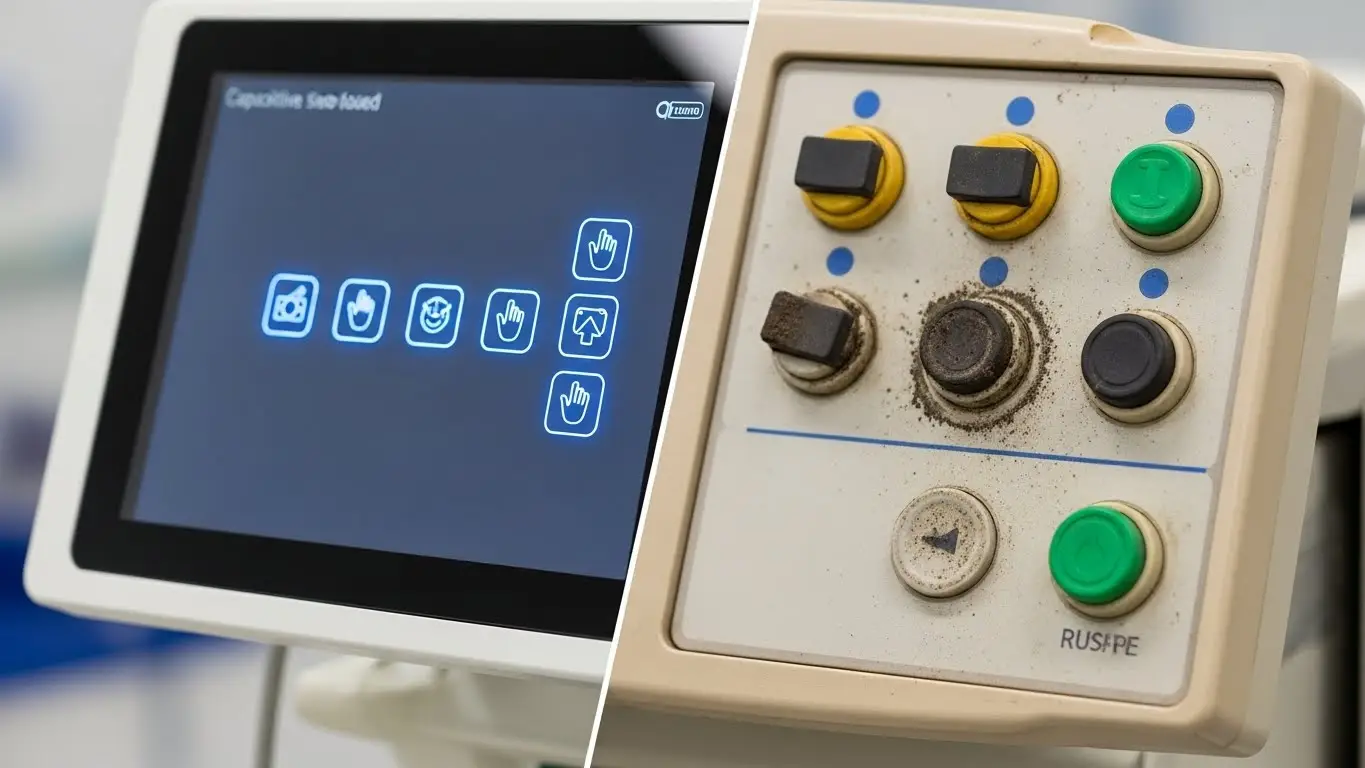

The best alternatives to micro tact switches depend heavily on your specific design constraints, but the top contenders are metal dome arrays (snap domes) for tactile feedback in ultra-thin profiles, and capacitive touch sensors for durability and waterproofing. If you need a rugged, sealed interface, piezo switches are superior. While micro tact switches are cheap and ubiquitous, they often fail due to mechanical wear or moisture ingress. Moving to these alternatives improves product longevity, allows for sleeker industrial designs, and eliminates the common failure points associated with moving mechanical parts.

What Are the Most Common Hardware Replacements?

When you simply need to replace the function of a button but can't use a standard tactile switch due to height or reliability concerns, you generally look at "naked" mechanical options or membrane solutions.

Metal Dome Arrays (Snap Domes)

A metal dome is essentially a tact switch without the plastic housing. It is a curved piece of stainless steel that sits directly on the PCB pads.

- Why use it: It reduces vertical height by over 50% compared to a standard switch while maintaining that crisp "click" users love.

- Best for: Remote controls, key fobs, and wearables.

If you are working on shrinking your product's footprint significantly, you should read our specific guide on alternatives to tact switches in compact devices, which dives deeper into space-saving strategies.

Membrane Switches

Membrane switches consist of printed conductive ink on flexible layers.

- Why use it: They provide a fully sealed front panel, making them excellent for medical devices or appliances where ease of cleaning is critical.

- Best for: Microwaves, medical control panels.

What Are the Best Solid-State Alternatives?

If you want to eliminate mechanical failure entirely, you need to go solid-state. This means no moving parts to wear out.

Capacitive Touch Sensors

Capacitive touch uses copper pads on the PCB to detect the electrical change when a finger approaches.

- Pros: Infinite cycle life; allows for a completely sealed, glass, or plastic unibody case.

- Cons: No physical feedback (requires haptics/vibration to confirm a press).

Piezo Switches

Piezo switches generate an electric signal when pressure is applied to a crystal.

- Pros: They work with gloves and are effectively vandal-proof. They can be sealed to IP68 or IP69K standards.

- Cons: More expensive than standard switches.

While upgrading your user interface, you might also be looking at internal board configurations. If you are modernizing your PCB, check out our guide on the best alternatives to DIP switches to see how to replace those bulky configuration blocks.

Are Membrane Switches Better Than Tact Switches?

Membrane switches are better than tact switches for environmental protection but often worse for tactile feedback.

A membrane switch is a sealed unit. It is ideal if your device is used in a kitchen or a hospital where it might get splashed with water or wiped down with harsh chemicals. A standard micro tact switch has a stem that allows dirt and liquid to enter the housing eventually.

However, membrane switches can feel "mushy." To fix this, high-end membrane keypads actually put a metal dome inside the membrane layer to restore the click feel.

How Do I Replace a Switch in a Waterproof Device?

To replace a switch in a waterproof device, use capacitive sensing or Piezo switches to eliminate holes in the enclosure.

The biggest weakness of a tactile switch is that it requires a physical hole in the case for the button actuator to move. This requires complex O-rings and seals.

- Capacitive Touch: Senses through plastic or glass (up to ~3-5mm thick). No holes required.

- Piezo: Detects the microscopic bending of a metal panel. You can machine a solid metal case with a thin spot for the button, maintaining a 100% solid metal surface.

Just as device interfaces are becoming more robust and sealed, the infrastructure connecting them is evolving too. For a broader perspective on rugged connectivity, see our article on industrial Ethernet switch alternatives.

Comparison Table: Choosing Your Alternative

| Feature | Micro Tact Switch | Metal Dome | Capacitive Touch | Piezo Switch |

| Tactile Feedback | Excellent | Excellent | None | Low/None |

| Life Cycles | 100k - 1M | 1M+ | Infinite | 50M+ |

| Waterproofing | Difficult | Medium | Excellent | Excellent |

| Cost | Lowest | Low | Low (if MCU exists) | High |

| PCB Space | Medium | Very Low | Zero (trace only) | Medium |

When Should I Stick to Mechanical Switches?

Sometimes, you just need a physical knob or dial. If your application involves selecting distinct modes or values (like channels on a radio), a simple button isn't enough. In these cases, you should compare when to use rotary switches vs. DIP switches to understand how rotary encoders or coded switches can offer a better user experience than repetitive button pressing.

Frequently Asked Questions

Standard capacitive buttons struggle with thick gloves. However, you can use high-sensitivity tuning or specialized "mutual capacitance" sensors to detect proximity through thin gloves. For heavy industrial gloves, Piezo or mechanical metal domes are better choices.

The component cost of a metal dome is very low, often cheaper than a switch. However, the assembly cost can be higher because they need to be placed accurately (pick-and-place) and covered with a retention layer (tape), whereas tact switches are standard SMT components.

Soft touch usually refers to silicone rubber keypads (like on a TV remote) that use a conductive carbon pill to bridge contacts. They are quiet and soft but lack the sharp "snap" of a metal dome or tact switch.

Standard capacitive buttons struggle with thick gloves. However, you can use high-sensitivity tuning or specialized "mutual capacitance" sensors to detect proximity through thin gloves. For heavy industrial gloves, Piezo or mechanical metal domes are better choices.