Alternatives to Tact Switches in Compact Devices: The Engineering Guide

Designing sleek wearables often forces you to seek alternatives to tact switches in compact devices. While the standard tactile switch has been the heartbeat of user interfaces for forty years, modern consumer expectations for waterproofing and slim profiles are rendering it obsolete. If you are struggling to fit a 3mm switch into a 2mm housing, you are not alone.

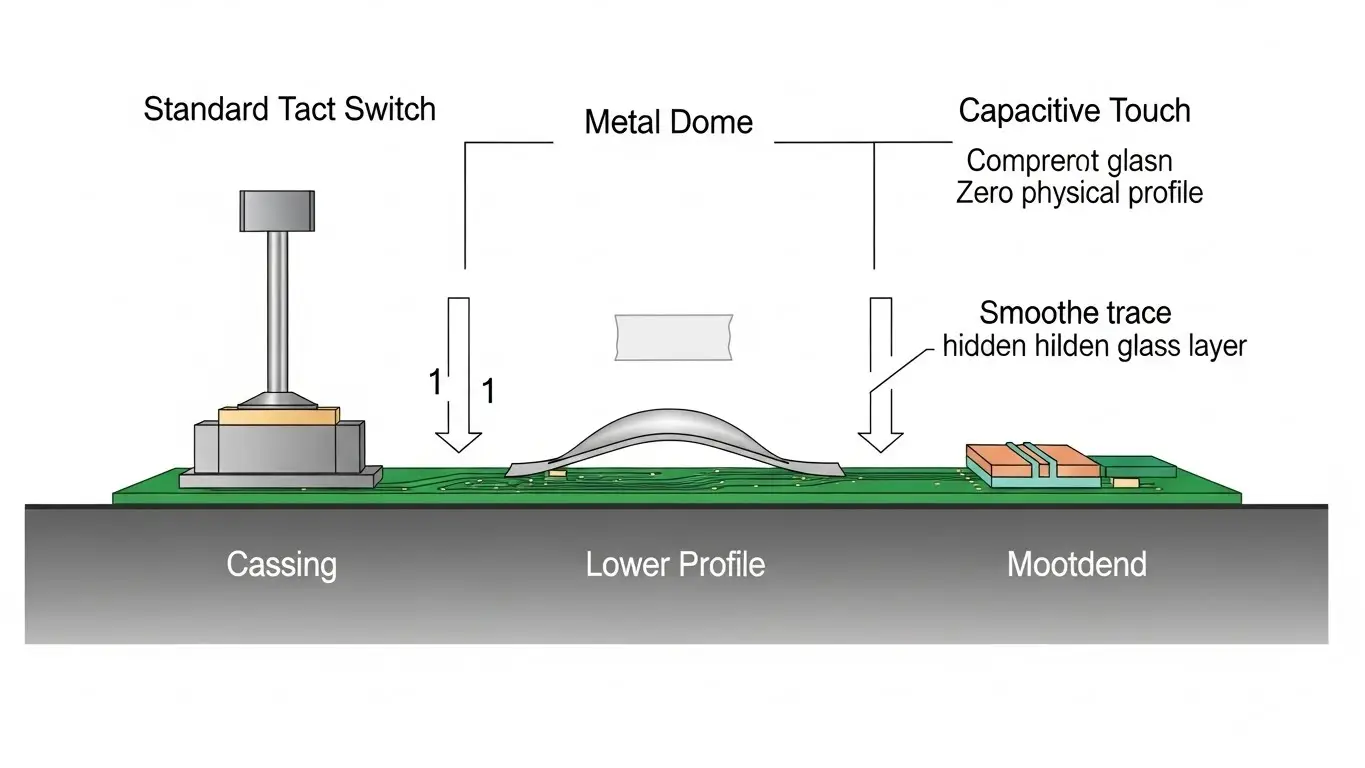

In this guide, we will dismantle the best low-profile and solid-state replacements for traditional electromechanical switches. We will explore how technologies like capacitive sensing and snap domes are revolutionizing product design without sacrificing user feedback.

What Are the Best Alternatives to Tact Switches in Compact Devices?

The best alternatives to tact switches include capacitive touch sensors for a sleek, sealed interface and metal dome arrays for ultra-low-profile tactile feedback. For harsh environments, piezo switches offer superior durability, while membrane switches provide a cost-effective solution for multi-button interfaces.

The Shift from Mechanical to Solid-State

I remember working on a handheld GPS project where we stuck with standard 6x6mm tact switches. They were reliable until the first field test in heavy rain. The seals failed, and the "click" turned into a "mush." That experience taught me a valuable lesson: the component that feels best on the bench isn't always the one that survives the real world.

When selecting an alternative, you are generally trading off between tactile feedback (the physical click) and durability/size.

1. Capacitive Touch Sensors (The Smartphone Standard)

This is the most common upgrade for modern IoT devices.

- How it works: Sensors on the PCB detect the change in capacitance when a finger approaches.

- Best for: Smartwatches, medical devices, and sealed enclosures.

- Pros: Zero moving parts, infinite cycle life, waterproof (IP68 capable).

2. Metal Dome Arrays (The "Naked" Switch)

If you strip the plastic housing off a tact switch, you get a metal dome.

- How it works: A stainless steel dome is taped directly to the PCB. Pressing it collapses the dome to bridge a circuit.

- Best for: Ultra-thin remote controls, membrane keypads.

- Pros: Retains the "click" feel but reduces height by 70%.

3. Piezo Switches (The Indestructible Option)

- How it works: Pressure on a crystal generates a voltage pulse.

- Best for: Vandal-proof interfaces, underwater equipment.

Why Should You Replace Standard Tact Switches?

You should replace standard tact switches to eliminate mechanical wear, improve ingress protection (IP ratings), and significantly reduce device thickness. Traditional switches introduce potential leak paths and require physical travel distance, which limits how thin a modern device housing can be.

The Height Constraint

In the world of wearables, Z-height is the enemy. A standard low-profile tact switch is about 1.5mm to 3mm tall. A metal dome is 0.4mm. A capacitive pad is effectively 0mm (just copper on the PCB). By switching technologies, you can shave millimeters off your device, which allows for larger batteries or slimmer aesthetics.

Reliability in Harsh Environments

Mechanical contacts oxidize. Springs fatigue. If your device is destined for an industrial environment, a standard tact switch is a ticking time bomb.

Interestingly, we see a similar trend in network infrastructure. Just as device designers are moving away from physical switches to software-defined controls, network engineers are moving toward more robust, managed solutions. For a broader look at upgrading infrastructure, see our guide on Industrial Ethernet Switch Alternatives, which parallels the shift from simple mechanical toggles to intelligent systems.

Is Capacitive Touch the Ultimate Solution?

Capacitive touch is the ultimate solution for aesthetics and waterproofing, but it lacks physical feedback. It allows for completely sealed enclosures and sleek glass fronts, yet it requires careful software tuning to distinguish between a finger press, water droplets, or accidental brushes.

Overcoming the "Phantom Touch"

The biggest hurdle with capacitive touch is "tuning." I once reviewed a prototype shower controller that turned itself on every time steam built up in the room. The sensitivity was too high.

To implement this successfully, you need:

- Haptic Feedback: Since there is no "click," use a vibration motor (LRA or ERM) to confirm the press.

- Water Rejection Algorithms: Modern microcontroller (MCU) drivers have dedicated logic to ignore rain or sweat.

- Wake-up Gestures: To save power, the sensor sleeps until a specific "double tap" or proximity event occurs.

How Do Metal Dome Arrays (Snap Domes) Work?

Metal dome arrays work by adhering a pre-formed stainless steel dome directly onto the PCB pads using an adhesive spacer layer. When pressed, the dome snaps down to close the circuit, providing a crisp tactile click with a travel distance of only 0.3mm to 0.6mm.

The Best of Both Worlds

If your users demand a click, but you don't have space for a switch, this is your answer. This is essentially how the buttons on your old flip phone worked, and it remains the gold standard for thinness.

- Peel-and-Place: You can buy "dome arrays" on a sheet. You simply peel them off and stick them to your board during assembly.

- Venting: You must design the PCB with via holes to allow air to escape from under the dome, otherwise, the air pressure will make the button feel stiff.

Pro Tip: Don't rely on the adhesive alone for alignment. Use alignment holes on the PCB to ensure the dome sits perfectly centered over the contact pads.

Comparison Table: Tact Switch vs. Alternatives

The following table compares the physical and electrical characteristics of the main alternatives to help you choose the right interface for your compact device.

| Feature | Tact Switch | Capacitive Touch | Metal Dome | Piezo Switch |

| Profile (Height) | High (>2mm) | Zero | Low (<0.6mm) | Medium |

| Tactile Feedback | Excellent | None (Requires Haptics) | Excellent | Low/None |

| Sealing (Water) | Difficult | Excellent (Sealed) | Good | Excellent |

| Life Cycle | 100k - 1M | Infinite | 1M+ | 50M+ |

| Cost | Low | Medium (MCU required) | Low | High |

| Best Application | Generic Consumer | Wearables / IoT | Remotes / Keypads | Vandal / Medical |

Export to Sheets

Decision Framework: The FAME Model for Switching

Use the FAME framework (Function, Atmosphere, Mechanics, Economics) to select your switch. If the device is exposed to water (Atmosphere), choose Capacitive. If the user wears gloves (Mechanics), choose Metal Domes or Piezo. If cost is paramount (Economics), stick to Domes.

Integrating Configuration Switches

While we are discussing user interface switches (momentary), do not forget the backend configuration. Often, compact devices also need internal settings changed during manufacturing. If you are struggling with bulky DIP switches inside your compact housing, you should read our deep dive on Best Alternatives to DIP Switches. It covers how to replace those bulky internal toggles with zero-profile options like solder bridges or EEPROM settings, saving even more precious board space.

Emerging Technologies: What is Next?

Emerging technologies like Force Sensing Resistors (FSR) and Ultrasonic Gesture control are the next frontier. FSRs allow for variable pressure input (soft press vs. hard press), while ultrasonic sensors enable touchless control, completely eliminating the need for surface contact.

The Rise of "Solid State Buttons"

Companies like Apple (with the trackpad) and various automotive manufacturers are moving toward "Force Touch." This combines a pressure sensor with a haptic engine. To the user, it feels exactly like a button moving, but physically, the surface never bends. This is the holy grail for durability, as there are no fatigue points.

Conclusion

The era of putting a bulky mechanical switch on a sleek wearable device is ending. By embracing capacitive touch for elegance or metal domes for tactile thinness, you can design products that look better and last longer.

The right choice depends on your user's environment. Does it need to work in the rain? Go Piezo or carefully tuned Capacitive. Does it need to fit in a credit-card-sized device? Metal Domes are your only path.

Frequently Asked Questions (FAQ)

The thinnest physical alternative is a metal dome (snap dome), which adds approximately 0.4mm to the PCB height. However, capacitive touch is effectively zero-profile as it uses copper traces within the PCB itself.

Generally, no. Standard capacitive sensors rely on the conductivity of human skin. However, high-sensitivity sensors or 'mutual capacitance' setups can sometimes detect proximity through thin gloves, but for heavy gloves, pressure-based switches (Piezo or Metal Dome) are superior.

Yes, membrane switches are inherently resistant to moisture and dust because the circuitry is sealed between layers of plastic. They are commonly used in medical and industrial applications where wash-down capability is required.

Yes. The PCB footprint for a metal dome consists of a central pad (or pads) and an outer ring pad. The dome sits on the outer ring and, when pressed, collapses to touch the center pad, completing the circuit.

For volume control, slider sensors (capacitive sliders) or linear force sensors are excellent replacements. They allow the user to slide a finger to adjust levels, which is more intuitive and durable than repeatedly pressing a button.