Compact Vibration Switch – Guide for Safety & Protection

What is a Compact Vibration Switch?

- A compact vibration switch is a protective circuit that reacts to abnormal machinery vibrations. Once vibrations breach a safe limit, the switch goes off; either the system is shut down or the user receives an alert. It is compact in nature, hence it is versatile and can be installed on a variety of applications.

- These monitoring devices are small and user-friendly, unlike big monitoring systems. You may refer to it as a mini vibration switch, micro vibration switch, or small vibration switch, but the concept remains the same: small design but maximum safety.

Key Features of a Compact Vibration Switch

- Lightweight and Compact Body

The small vibration switch has a light structure, which makes it easy to fit on any machine or control panel. It is small and is therefore flexible in its use where there is a scarcity of space, as is the case with pumps, motors, or HVAC systems.

- Quick Response to Vibration Changes

The fast response time has been one of the most useful features. The switch identifies the level of abnormal vibration immediately and avoids the expensive idle time, and limits the sensitive equipment from being damaged severely.

- Mechanical or Electronic Options

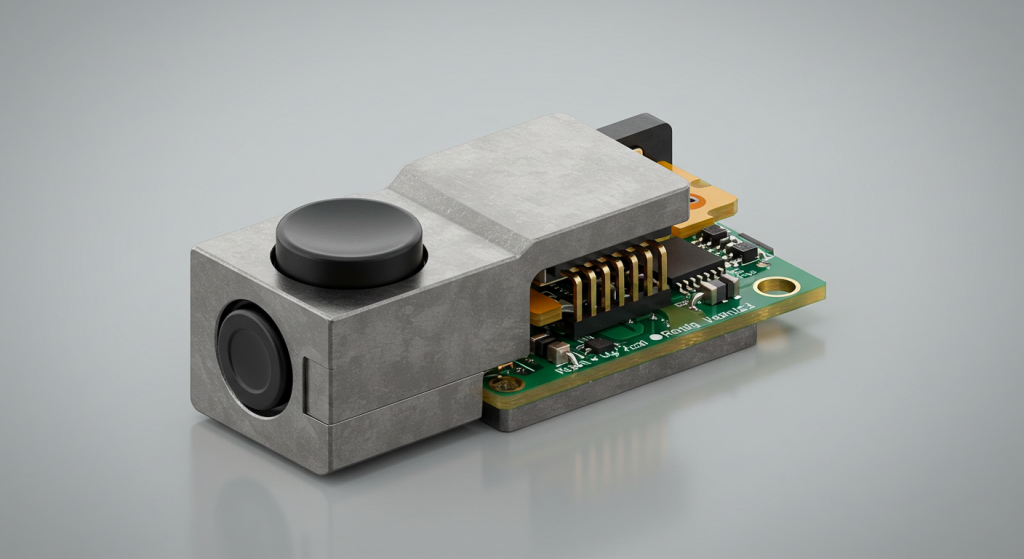

These switches come in mechanical vibration switch as well as electronic vibration switch designs. Simple, rugged, and needing no power supply are the mechanical types; more precise and advanced monitoring is provided in the electronic versions.

- Easy Integration into Industrial Systems

Compact vibration switch are created to easily integrate with automation systems in industry. They may be hard-wired to alarms, relays, or control circuits, allowing them to run smoothly.

- Long Service Life with Low Maintenance

Constructed using resistant materials, such switches ensure long-term functionality. They need little maintenance and are, hence, a cost-effective option to industries that need to minimize downtimes and maintenance expenses.

Why a Compact Vibration Switch?

- Equipment Protection

The vibrations are inherent in machines. But excessive vibrations signal problems such as imbalance, wear, or misalignment. A vibration detection switch eliminates serious damage as an equipment protection switch.

- Cost-Effective

Downtime means lost revenue. Thousands can be saved by using a low-priced vibration switch to prevent equipment failure.

- Regulatory Compliance

Several industries have to fulfill safety regulations. A vibration safety switch is used to prevent non-compliance and expensive fines.

- High Sensitivity

The high-sensitivity vibration switch used in modern models is sensitive to slight vibrations so that they can be monitored.

Product Description

• Rated Value: DC12V 50mA

• Contact Resistance: ≤100mΩ

• Insulation Resistance: >100MΩ

• Operating Force: 250±50g

Application Field

Switches are used to operate all varieties of electronic devices, including audio equipment, office devices, communications equipment, measuring devices, television sets, and VCRS.

Why Choose Us?

When one decides to use Hanxia, they decide to use the promise of good quality, reliability, and high-quality services. These are the reasons why we will be trustworthy:

- Rich Industry Experience

Hanxia has managed to work in the area of electronic components manufacturing for 10 years since its creation in 2014. We have over 7,500 customers in most parts of the world, including the United States, Germany, South Korea, Taiwan, and Hong Kong.

- Optimal Automated Production

38 automated production lines: In daily production, over 2 million pieces are produced, which guarantees that orders are delivered on time.

- Advanced Technology:

Development of technical cooperation with Korean counterparts, the adoption of fully automatic production of assembly technology, which is able to produce products successfully with the reduction of human error.

What is the Mechanism of a Compact Vibration Switch?

- Mechanical Type: A mass with springs attached to it moves in response to vibrations that are more intense than the present level. The movement causes a contact, either breaking the power or an alarm.

- Electronic Type: Accelerometers or piezoelectric sensors are used as a sensor of motion vibration. It is further processed into the signal, which is converted to an output that safeguards the machine.

Benefits of Using Compact Vibration Switches

• Early Detection: Identifies misalignment or wear before failure.

• Compact Size: Suitable for space-limited applications.

• Diversity: Can be applied as a mini vibration alarm switch.

• Durability: Can work in high temperatures.

• Cost Savings: Reduces downtime and maintenance costs.

Technical Specifications

Although specifications are different, the general parameters are:

• Sensitivity: Adjustable from 0.1 g to 50 g.

• Power Supply: 5V–24V DC.

• Temperature Range: -40°C to +85°C.

• Output: Relay, transistor, or digital.

• Mounting: PCB, panel, or in-line connectors.

The switch is applicable in several industries due to these technical features.

The Right Compact Vibration Switch.

When selecting, consider:

- Application Type- Industrial, consumer, marine, or aerospace.

- Sensitivity Level- In the case of precise machines, high-sensitivity vibration switches should be used.

- Environment- Choose waterproof or durable models to be outdoor use.

- Budget- Choose between low-cost vibration switches or premium options.

- Size Constraints- A Micro vibration switch is preferred in small systems.

Trends in Vibration Switch Technology

- IoT Integration: Switches that are linked to networks to monitor in real-time.

- Energy Efficiency: Low power consumption designs.

- Miniaturization: Smaller switches with high sensing capability.

- Smart Sensors: Hi-Tech Vibration sensors (analytics).

Conclusion

Small in size, the compact vibration switch has a gigantic impact on industrial safety. These devices protect against mechanical failures in case of motors and pumps, marine vessels, and turbines. They are affordable, user-friendly, and necessary to maintain the health of the machine in the long term. When one decides to invest in the correct vibration switch, then that investment will ensure not only the equipment but also productivity and safety. A smaller-than-usual vibration switch is not a choice; it is a necessity for industries that want to reduce risk and enhance efficiency. Visit Hanxia.