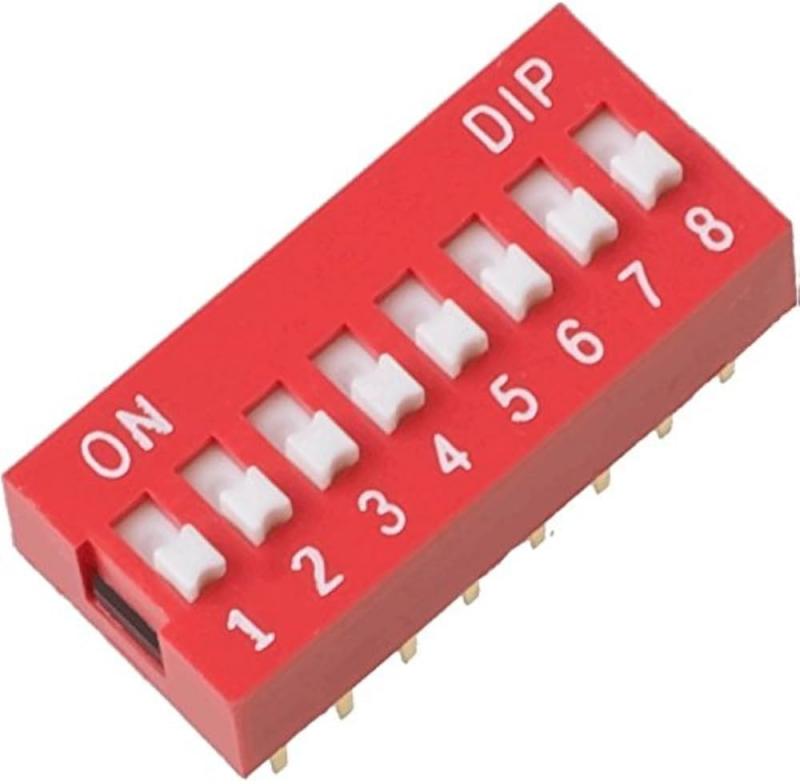

How a 8 Position DIP Slide Switch Improves Circuit Flexibility

An 8 Position DIP Slide Switch is a compact onboard selector with eight on/off toggles that configure device settings - addresses, modes, or features - without firmware changes, enabling quick, reliable customization during assembly or service. 8 Position DIP Slide Switch solutions give engineers a fast, reliable way to unlock flexible configurations without rewriting firmware or redesigning a PCB. But what separates a flexible design from a fragile one? Let's open the board and see.

From Fixed Boards To Flexible Platforms

An 8 Position DIP Slide Switch places eight binary selectors in a compact footprint. Each position can enable or disable a function, choose a mode, or set an address. The practical benefit is simple: the same PCB can serve multiple product tiers, local regulations, or customer-specific options. Instead of maintaining several board spins, you ship one platform and configure it at the factory line - or in the field - within seconds.

In day-to-day engineering, the switch often becomes a tiny "control panel" on the PCB. Teams use it to set bus addresses, limit current, adjust gain stages, or toggle diagnostics. No laptop on the line. No hidden menus. No extra microcontroller pins tied up by jumpers. A technician flips a few actuators and moves on, saving minutes per unit and hours across a batch.

Space and reliability are the real pain points. Devices keep shrinking while warranty costs keep climbing. A well-designed 8 Position DIP Slide Switch tackles both. It packs dense configuration into millimeters of board area and maintains stable contact resistance over time. That combination - high configurability with low overhead - protects margins and schedules.

- Where An 8 Position DIP Slide Switch Pays Off:

• Mode Selection: Eco vs. performance, regional settings, safe vs. high-power.

• Addressing & ID: Assign RS-485, CAN, or logic-line addresses without a code change.

• Feature Gating: Enable premium features on a shared hardware platform.

• Service & Calibration: Turn on logging, diagnostics, or factory tests quickly.

Inside Hanxia: Reliability You Can Specify

At Hanxia, reliability starts with precision engineering. Our 8 Position DIP Slide Switch designs focus on consistent actuation force, crisp detents, and secure, low-bounce contacts. That combination fights the two silent profit killers: misconfiguration and intermittent faults. When a switch reads the same today, next month, and after vibration in the field, teams avoid hours of fruitless firmware debugging.

We also design for the full product lifecycle. On the assembly line, clear legends, consistent feel, and intuitive orientation reduce operator errors. In the field, tactile feedback and defined on/off positions help prevent accidental toggling. For service teams, the state is visible at a glance - no laptop, no special probe, no guessing. That is practical flexibility you can measure.

✅ Why Choose Hanxia DIP Switches:

• High-Precision Design - Manufactured with precision engineering to ensure reliable switching and consistent operation.

• Wide Range Of Options - Available in multiple configurations, including slide, rotary, and piano-style DIP switches.

• Reliable Performance - Built for minimal wear and tear to support a long lifespan.

• Secure And Stable Contacts - Firm electrical contact helps prevent misreads and misconfiguration.

• Industry-Standard Compliance - Meets global safety and performance expectations across applications.

Beyond fundamentals, Hanxia pays attention to details that reduce hidden costs. Contact geometry, plating choices, and materials control help keep resistance stable and bounce predictable. Easy-to-read markings cut training time. And consistent actuation force across lots means your work instructions remain valid even when supply scales. The result is fewer RMAs, fewer line stoppages, and cleaner post-deployment data.

Selecting The Right 8 Position DIP Slide Switch

Choosing a switch is about context - electrical, mechanical, and human:

• Actuation & Access: Will operators use a tool or fingertips? Is orientation obvious on a crowded PCB?

• Electrical Margins: Confirm voltage/current levels for your logic scheme and any pull-ups or filtering.

• Contact Stability: Favor designs with low, consistent contact resistance and anti-vibration resilience.

• Markings & Human Factors: Crisp legends and firm detents reduce assembly and service errors.

• Compliance & Testing: Validate safety and environmental requirements (e.g., RoHS/REACH) for your market.

Practical Design Tips And Real-World ROI

Plan for both the schematic and the human experience. Place a clear truth table near the footprint on the silkscreen or in the service guide. Use pull-up/pull-down networks that default to a safe configuration. If your system is sensitive to switch bounce at power-up, consider small RC filters or a brief firmware debounce on first read. Sealed products may need an access window or gasketed door so technicians can toggle settings without disassembly.

From a system perspective, map the eight positions like capability flags. For example, dedicate 1-4 to addressing, 5-6 to operating modes, and 7-8 to service. This approach shortens training, simplifies audits, and prevents accidental feature overlap. Many teams also log the readback value on boot; this creates a quick health check and an audit trail for returned units.

Not every control deserves a touchscreen or a firmware build. Often, the fastest, most robust answer is mechanical - and that's where the 8 Position DIP Slide Switch shines. It translates design intent into repeatable factory actions and reliable field behavior, with very little to go wrong. When deadlines are tight and variants multiply, this quiet component can be the difference between chaos and control.

CTA - Configure With Confidence

Planning a new design or stabilizing an existing platform? Hanxia can help specify the optimal 8 Position DIP Slide Switch for your environment, assembly process, and compliance needs. Our engineering team supports samples, customization, and quick evaluations. Contact Hanxia to discuss your application and accelerate your next build with reliable, flexible switching.