Technical Specs of the 22mm Push Button Switch

22mm Push Button Switch users expect every press to feel right, register fast, and keep working for years. At Hanxia, we build for real production floors and crowded panels, not lab benches. Our perspective is simple: the switch should be easy to integrate, predictable in operation, and resilient under real-world stress - from hot enclosures to quick operator taps on a busy line. Below, we explain the design choices that matter, share a representative product snapshot, and show how Hanxia's manufacturing turns specifications into dependable performance at scale.

Design Features of the 22mm Push Button Switch

In modern control cabinets, space is tight and downtime is costly. Our design framework centers on five pillars: long-lasting reliability, precise actuation, compact geometry, low power draw, and broad application compatibility. Each pillar addresses a common pain point that engineers face during selection, qualification, and maintenance.

1) Reliable Actuation, Press After Press

Reliability is a function of materials, tolerances, and process control. We focus on dimensional stability in the actuator and return mechanism so the tactile response does not drift as the switch ages. Clean electrical contact is just as important. Stable, low contact resistance helps prevent nuisance faults and keeps signals crisp for PLC inputs. Our target is consistency across the rated life, not just a perfect first week. That is why we validate against contact wear, verify insulation resistance, and confirm dielectric strength under real use conditions. This approach preserves the "yes, it clicked" feel that operators rely on during repetitive tasks.

2) Compact, Efficient, and Easy to Integrate

Panel real estate is precious. A panel mount 22mm push button switch must deliver performance without demanding excessive depth behind the plate. We design compact bodies that fit dense layouts, simplifying wiring and airflow. Low power consumption also matters. In systems with many indicators and inputs, cumulative current becomes heat, and heat shortens life. Our low-current philosophy reduces heat load and eases power budgeting. Finally, compatibility across voltage levels and device types speeds up engineering; a single switch family that suits multiple machines reduces part numbers and vendor complexity.

✅ Common problems our design addresses include:

- Mis-triggers caused by vague or "mushy" feedback

- Panel crowding where deep components block neighboring devices

- Power budgets strained by inefficient components

- Mixed fleets that need one switch family for many uses

- Maintenance costs linked to unstable contact behavior

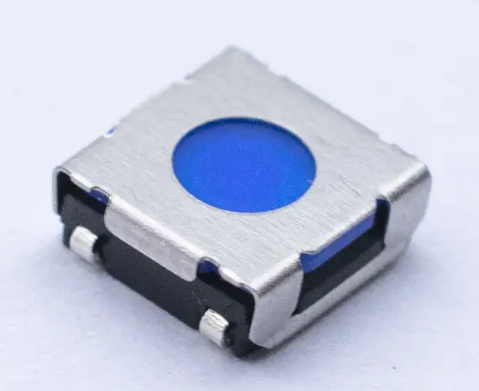

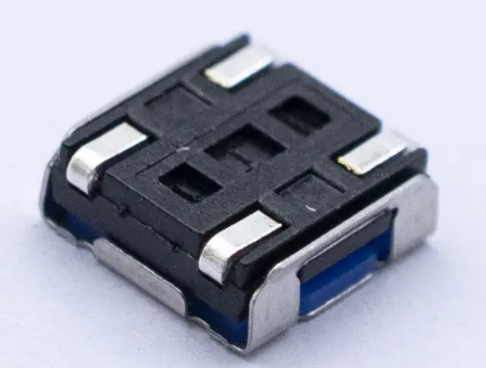

Hanxia's Tactile Switch for Laptop Push Button

While the 22mm series serves panel applications, our approach to tactile clarity and electrical stability is exemplified by Hanxia's Tactile Switch for Laptop Push Button. Built for portable electronics, it shows how we translate design intent into measurable performance.

✅ Key Parameters You Can Count On

- Operating Temperature: -25 to 70℃

- Relative Humidity: ≤80%RH

- Rating: 50mA 12V DC

- Contact Resistance: ≤100mΩ

- Insulation Resistance: ≥100mΩ

- Operating Force: 250gf ±50gf

- Dielectric Strength: 250V 50Hz 1min

- Contact Journey: 0.25 ±0.1mm

- Lifetime: 100,000 cycles

In use, the switch delivers reliable tactile feedback with a crisp, repeatable profile. The controlled operating force makes presses intentional, not accidental, which is critical when users interact quickly or wear light gloves. The compact form factor makes PCB and enclosure design easier, especially in thin devices where every millimeter matters.

Typical applications include audio apparatus, office equipment, communication devices, measuring instruments, TV sets, and VCRs. Although this model is tailored to laptops and compact electronics, the same principles - reliability, precise actuation, compactness, efficiency, and wide compatibility - guide our industrial control 22mm push button switch portfolio for panel-mounted HMIs. The result: cohesive design logic across products, smoother qualification, and fewer surprises during scale-up.

From an engineering viewpoint, these parameters make procurement and compliance checks more predictable. Known operating limits reduce the guesswork in thermal analysis. Defined force and travel help mechanical teams fine-tune enclosure openings and legends. Clear electrical ratings streamline schematics and derating plans. It is a product snapshot that mirrors how we build 22mm devices for control cabinets: practical, measurable, and consistent.

Why Choose Hanxia

Hanxia has been manufacturing electronic components since 2014. Today, we support 7,500+ customers across the United States, Germany, South Korea, Taiwan, and Hong Kong. Our mission is to merge application insight with industrialized production so you can launch quickly and keep quality steady from prototype to volume.

1) Capacity and Speed Without the Guesswork

High-mix, high-volume programs need reliable output. Hanxia operates 38 fully automated production lines with a daily capacity exceeding 2 million units. Automation helps us hit tight tolerances repeatedly and shortens lead times during ramp-ups and EOL transitions. We also collaborate with Korean partners on fully automated assembly processes that reduce human error and stabilize the tactile curve from lot to lot. For buyers and planners, that means simpler scheduling and fewer last-minute deviations. To de-risk sourcing, we offer fast, worry-free delivery backed by a 90-day no-questions-asked return policy - a practical safeguard when qualifying new builds.

2) Quality You Can Measure - and Rely On

Quality is a process, not a slogan. We monitor every stage: raw material inspection, in-line sampling, and final testing. Our 100% factory inspection ensures each unit meets expectations for electrical performance and tactile feel. Measurable targets guide everything we do: stable contact resistance, consistent operating force, and preserved tactile signature across the rated life. This discipline reduces field failures, lowers total cost of ownership, and keeps operators confident in every press.

For engineers, the effect is tangible. Qualification cycles run smoother because prototypes behave like production units. For maintenance teams, consistent feel means faster training and fewer second-guess presses. For operations managers, stable parts mean fewer line stops and cleaner data from the HMI layer.

Call to Action - Start Your Project with Hanxia

Evaluating a 22mm Push Button Switch for a new panel, updating an HMI, or qualifying a tactile switch for a compact device? We can help. Request samples, a fast quote, or a short engineering review to match your operating environment, expected lifetime, and integration needs. Hanxia turns clear design goals into switches that perform - press after press.