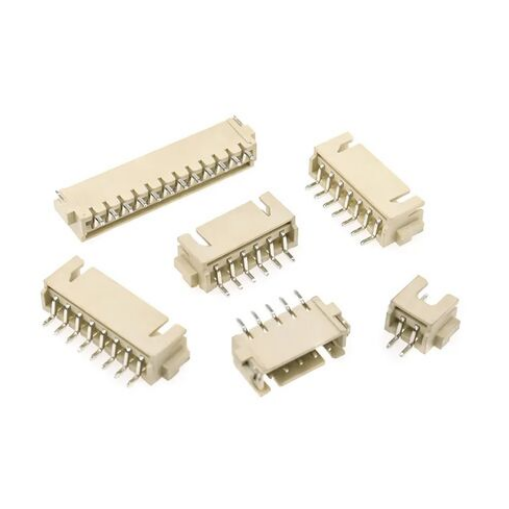

1.25mm 2mm 2.54mm Wafer Connector

1.25mm 2mm 2.54mm Wafer Connector choices shape board layout, cost, and performance. The right pitch is not a box to tick; it is a design call with budget impact. On Hanxia's lines, we see the same pattern again and again. Wins come from clear trade-offs between space, current, signal behavior, and assembly flow. In this article, we share a practical map you can use today - yet one detail often surprises even senior teams. We will come back to that twist near the end.

What Changes With Pitch

Selecting between 1.25mm, 2mm, and 2.54mm sets the tone for everything that follows. It shapes the PCB, the harness, and even the service model in the field. Think of pitch as a design lever you can pull to rebalance constraints.

- Space And Layout

Small pitch saves space. 1.25mm fits dense consumer boards and slim housings. It lets you place more I/O in less area. Traces get short. EMI risk can drop when routing is tidy. The cost is tighter tolerances. Placement needs discipline. Rework is harder.

2mm is the middle ground. It relaxes pad sizes and clearances. It still keeps the product compact. It is a popular step up when teams outgrow 1.25mm density but want to avoid a large footprint change.

2.54mm favors comfort and speed. Pads are wide. Test access is easier. Manual work is safer. This pitch fits legacy backplanes, industrial controls, and fast prototyping. If your crew will unplug and replug during maintenance, the bigger pitch helps.

- Power And Signals

Contact geometry scales with pitch. With 1.25mm, current is usually modest and wire gauges stay lean. It shines in low-to-medium power and compact harness designs. 2mm handles longer duty cycles and higher pin counts without crowding copper. 2.54mm offers generous contact area and sturdier wire choice. It tolerates repeated mating and field stress.

For signals, stability matters more than size. Short routes, solid grounds, and clean contact plating protect impedance at any pitch. What changes is margin. Tighter pitches offer less room for error and ask for better process control.

- Reliability And Service

Field reliability is not only the connector; it is the ecosystem around it. 1.25mm needs precise crimp quality and strain relief. 2mm lowers the risk of nicks and bent terminals during harness prep. 2.54mm forgives more handling and speeds up diagnostics. If you have many SKUs, a consistent pitch family reduces training time and spare-parts overhead.

Design Trade-Offs You Can Measure

Many teams debate pitch by preference. We suggest a short scorecard instead. It removes guesswork and aligns engineering with sourcing and quality.

1) The Scorecard Inputs

- Envelope And Density

How tight is the enclosure? What is the I/O per square centimeter target? If the goal is maximum I/O, 1.25mm 2mm 2.54mm Wafer Connector trade-offs begin with footprint math.

- Thermal And Current

List steady-state current per line and duty cycle. Add headroom for transients. Map temperature rise to contact size and copper area.

- Signal Integrity

Note edge rates, return paths, and layer stack. Shorter routes help, but connector plating, contact flex, and bow also matter.

- Assembly Flow

Who builds it and how? 1.25mm demands precise placement and careful harness prep. 2mm eases jig design. 2.54mm speeds manual touch-ups and pilots.

- Service Model

Will users or technicians unplug connectors in the field? If yes, durability and finger access can outweigh compactness.

2) Cost Beyond Unit Price

Total cost beats unit price. Scrap, rework, and returns often trace to the earliest pitch decision. 1.25mm can lower material use and shrink the PCB. But it increases sensitivity to process drift. 2mm reduces tool wear and improves first-pass yield for many factories. 2.54mm cuts pilot risk and training time. The cheapest BOM line can become expensive if it adds time or failure modes.

A simple exercise helps. Build two trial harnesses: one at the smaller pitch and one step up. Time the crimp, insert, and mate operations. Log the touch-up rate. The delta you measure is more honest than any estimate.

3) The Often-Missed Detail

Teams compare pitch, current, and space. They forget service loops. Cable bend radius and strain relief geometry must fit the enclosure. A connector can pass every lab test and still fail in the box build if the harness kinks. Before freezing the pitch, place the real harness in the enclosure mock-up and shut the lid. That five-minute check prevents months of churn.

Why Hanxia Reduces Risk, Not Just Size

Hanxia is a manufacturing partner, not only a catalog. We build connectors to tighten your margins and shorten your launch. Our view comes from building at volume and seeing what breaks first.

- Deep Experience - Over a decade in precision connector production. Faster DFM feedback. Smoother ramps.

- Automated Lines - Stable, high-consistency output across 1.25mm 2mm 2.54mm Wafer Connector families.

- Tough Quality Gates - 100% testing for durability, signal integrity, and power efficiency. We guard your design margins.

- Broad Compatibility - Options for varied voltage, current, and data rate needs. One supplier, multiple product tiers.

- Custom And OEM Work - We shape layouts, polarizations, locking features, and contact counts to your envelope.

- Global Logistics - Fast, secure shipping keeps pilots and mass builds on schedule.

Beyond the headline features, we focus on details that quietly lower cost:

- Polarization And Keying to prevent mis-mating during line changeovers.

- Housing Materials that tolerate reflow heat and light touch-ups.

- Harness Guides matched to wire gauges and bend radius.

- Footprint Libraries and pad advice that speed PCB release.Test Fixtures that trim EVT/DVT cycles and raise coverage.

When you share constraints, we answer with drawings, DFM notes, and a simple path to samples. The goal is not to sell the smallest pitch. The goal is to deliver the most forgiving product at the target size.

Final Words

If you are weighing 1.25mm 2mm 2.54mm Wafer Connector options for a new build - or planning a cost-down on a current design - send Hanxia your enclosure sketches, current targets, and service model. We will propose the right pitch, outline risks, and provide samples with a reliability plan. Contact Hanxia today for design guidance and a fast quote.

What about that twist we mentioned? Many teams pick the pitch, then scale the harness. We often reverse it. Start with the harness path and the service loop. Then let the pitch fall out of the space and bend-radius math. In our next piece, we will show a quick method to do exactly that.